| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Plastic Pipe Machine |

|---|---|

| Brand Name: | Friend |

| Model Number: | SJSZ |

| Certification: | CE |

| Place of Origin: | China |

| MOQ: | one set |

| Price: | negotiation |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 25 sets per month |

| Delivery Time: | 30 days |

| Packaging Details: | Film package,if wooden case needs extra charge |

| Raw material: | PVC powder |

| Motor power: | 18.5kw,37kw |

| Condition: | new |

| L/D: | 25:1 |

| Application: | PVC electric pipe |

| Inverter: | ABB |

| After-sales Service Provided: | Engineers available to service machinery overseas |

| Warranty: | 12 months |

| Company Info. |

| Zhangjiagang Friend Machinery Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

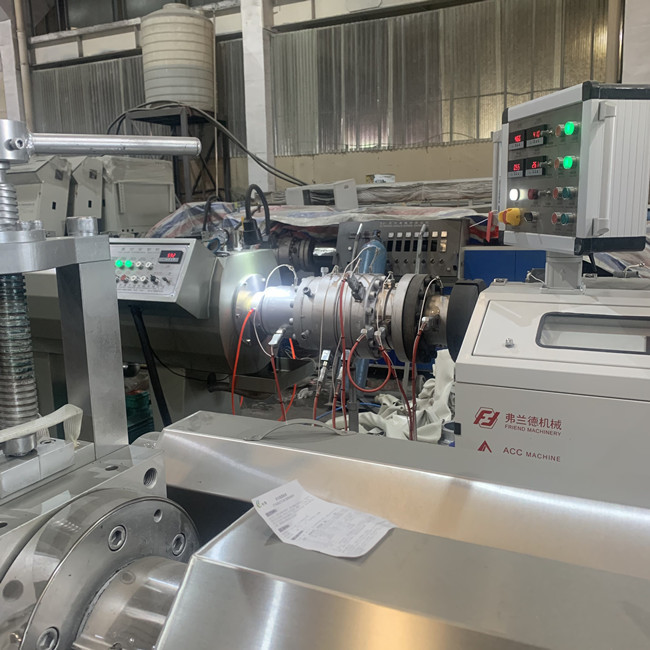

PVC Pipe Machine 16-63mm Electrical Water Pipe Plastic Pipe Machine

Details

PVC pipe extruder machine /VC pipe making machine/PVC pipe extrusion line is mainly used in the manufacture of the UPVC and PVC pipes with various tube diameters and wall thickness such as the agricultural and constructional plumbing, water supply and drain etc.

This set is composed of conical twin-screw extrude, vacuum calibration tank, haul-off machine, cutter, stacker etc. The screw extruder and traction machine adopt imported AC frequency control device. The vacuum pump and traction motor both adopt advanced products. The haul-off machine has many models, such as two-claw, three-claw, four-claw, six-claw etc. It may choose visual blade or cutting type.The unit is of reliable performance and high production efficiency.

Our machine can produce the PVC pipe with diameter from 16mm to 630mm

Advantages

The innovative technology of our extruders allows us to create versatile lines for the processing of plastic and new thermoplastic materials.

Completely customisable lines, whose winning feature is their ability to adapt perfectly to any technical need. We also offer ongoing support, which starts during the pre-sales analysis phase and continues with a reliable and comprehensive assistance an supply service.

Motorisation

Single static frequency converter. Both mechanical and electronic

synchronism makes the motor rotation more constant and increases

the machine efficiency.

Frequency converter

Chosen for the motorisation of our extruders, it guarantees the

same speed of the four motors, greater energy savings, lower instal

lation and maintenance costs, more solidity and durability over

time and perfect power distribution across all motors.

Thrust system

The multi-stage thrust bearings used on MD twin screw extruders

make it possible to triple the dynamic load and make the extruders

ideal for managing high production levels.

Feeding systems

It is possible to equip each machine with customized feeding

systems. This ensures adjusting the layout of the line and its

technical characteristics to the material to be processed and to

any specific production requirement.

PLC touch screen

Each extruder mounts a PLC control panel with touch screen, with

the possibility of controlling each phase remotely.

Moreover,algorithms and mathematic formulas allow processing the

energy consumption.

Cooling System

The correct thermoregulation of the barrels and screws is the key

to obtain high quality extruded products. That's why we have

developed an advanced, efficient cooling system, reliable at any

production speed.

Application

PVC Plastic pipe extrusion line is mainly used in Water supply pipelines, Sewage pipelines & Rainwater drainage pipelines & Air conditioning condensate water systems & Electrical conduit pipelines etc. The unit consists of Conical (Parallel) double screw extruder-PVC pipe mold-Vacuum forming tank-Haul-off machine-Cutting machine-Stacker/Belling machine. And the line can be equipped with Comptroller thickening instrument, computer ink-jet printer, crusher, shredder, Pulverizer ,water chiller, air compressor etc. to achieve the production and manufacture of high-grade tubing. Advanced design for screws and barrel supplies powerful safeguard for the PVC plasticization.

Main Technical Parameters

| Mode | Pipe Range(mm) | Extruders | Max. Output(kg/h) | Max. Speed(m/min) | Total Power(kw) | Line Length(m) |

| PVC-50*2 | 16-50 | SJSZ51/105 | 150 | 6 | 60 | 20 |

| PVC-63 | 16-63 | SJSZ45/90 | 120 | 10 | 45 | 20 |

| PVC-110 | 50-110 | SJSZ51/105 | 150 | 6 | 60 | 24 |

| PVC-160 | 63-160 | SJSZ65/132 | 300 | 5 | 100 | 24 |

| PVC-250 | 110-250 | SJSZ80/156 | 400 | 3.5 | 120 | 28 |

| PVC-315 | 160-315 | SJSZ80-156 | 400 | 3 | 160 | 28 |

| PVC-450 | 250-450 | SJSZ92/188 | 700 | 1.5 | 200 | 36 |

| PVC-630 | 315-630 | SJSZ92/188 | 700 | 0.9 | 230 | 36 |

More Product Pictures

|