| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Multi Cavity Injection Molding |

|---|---|

| Brand Name: | Gennki |

| Certification: | ISO9001 / TS 16949 |

| Place of Origin: | China |

| MOQ: | 1 mold |

| Price: | discuss base on certain RFQ |

| Payment Terms: | T/T |

| Supply Ability: | 12 sets/monthly |

| Packaging Details: | plastic film wrapped or vacuumed, and sustained in the wooden crate |

| Delivery Time: | 45 days~60 days |

| Application: | Household appliance |

| Mold steel: | NAK80 or 2344 |

| Cavity No.: | corresponding to customer's production needs |

| Standard: | International standard, easy replacement |

| Surface: | SPI or Mold-tech standard |

| Mold life: | 500K ~1M shots |

| Plastic Material: | PP |

| Design software: | Solidworks, Proe, Catia, UG |

| Company Info. |

| Gennki Group |

| View Contact Details |

| Product List |

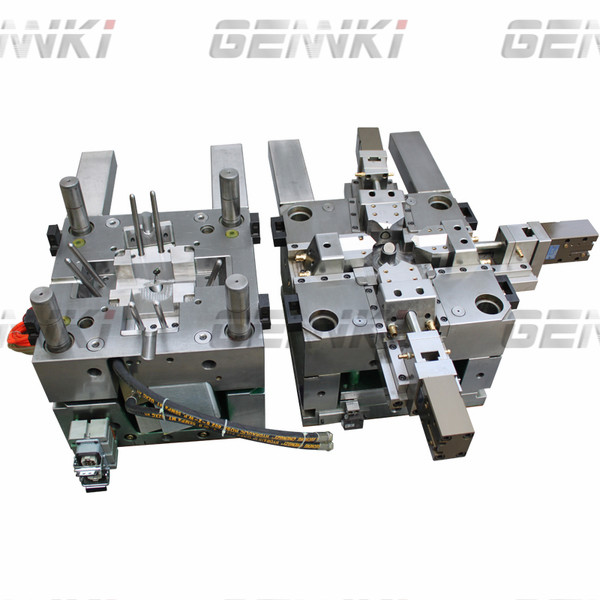

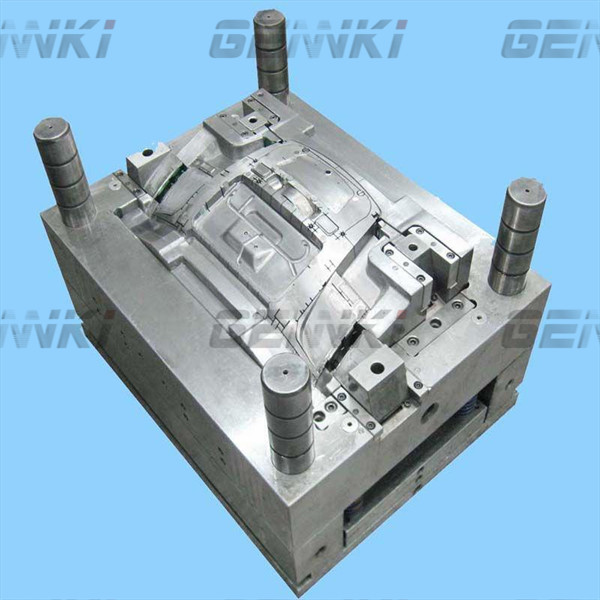

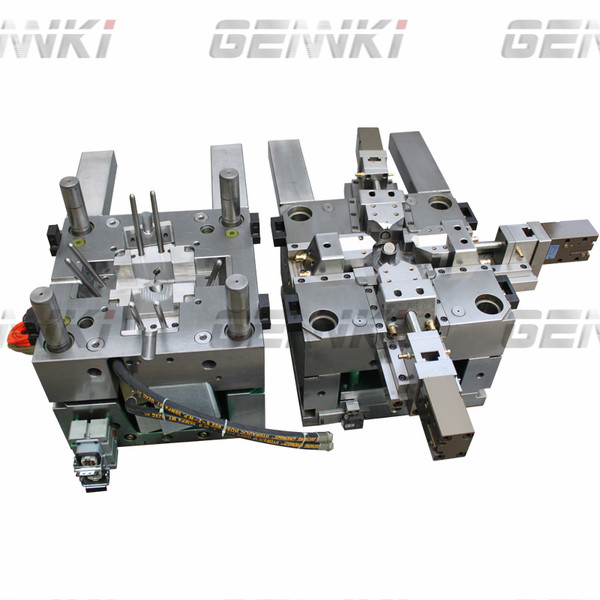

Freezer molding part by Plastic Injection Molds

From chest freezers and upright freezers to portable freezers and commercial freezers – we have involved all main elements which are built through the injection molds or aluminum die casting molds for customer's production requirement.

At Gennki, providing the customers the turn-key solution from the concept to the real product, are committed to manufacturing the products for end-users efficiently. That signifies working closely with each of our customers, from concept, part design, design analysis prototype, and production fulfillment of injection molds/molding, aluminum die casting, stamping, and assembly.

Product Description | Make injection molds and produce plastic injection molding parts |

| Plastic Materials: | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS, PEEK, HDPE, TPU, PET, PPO,...etc. |

| Other materials: | Rubber, Slilcone rubber, LSR, Aluminum, Zinc, Copper...Metal...etc. |

| Quality: | RoSH and SGS standard |

| Feature: | Non marking and Non flash |

| Size: | According to your 2D or 3D Drawing |

| Color,Quantity,Unit price,Tooling cost,Tooling size: | To be discussed |

| Package: | Standard exported Wooden box packed, Fumigation process(upon required) |

| Mold Building Lead Time: | T1, 4-5 weeks, Part measurement report (upon required). |

| Export Country: | Europe, America, Australian, UK, Canada, France, Germany, Italy, Japan...etc.: |

| To be discussed | In-Mold Decoration, Injection Mould, Plastic Mold, Overmould, 2K Mould, Die-Casting Mould, Thermoset Mold, Stack Mold, |

| Interchangeable Mold,Collapsible Core Mold, Die Sets, Compression Mold, Cold Runner System LSR Mold,...etc. | |

| Mould Base: | Hasco Standard, European Standard, World Standard |

| Mould Base Material: | LKM, FUTA, HASCO, DME,...etc. Or as per Customer's requirment. |

| Surface Finish: | Texture(MT standard), High gloss polishing |

| Cavity/Core Steel: | P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 ...etc. |

| Hot/ Cold Runner | HUSKY, INCOE, YDDO, HASCO, DME, MoldMaster, Masterflow, Mastip |

| Mould Life: | 5,000 to 1,000,000 Shots. (According to your working environment.) |

| Design & Program Softwares: | CAD, CAM, CAE, Pro-E, UG, Soildworks, Moldflow, CATIA....etc. |

| Facilities: | High-speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder,

Plastic Injection Molding Machine for trial out mold from 50-3000T |

Frequently Asked Question:

Q1. What is required of RFQ?

1) 3D formats with .stp.(preferred) igs,.prt.

2) 2D drawing for tolerance/material/surface finish/test requirement/regulations

3) Quantity (by order, month and Year)

Q2. How do you ensure product quality?

Gennki applies assessment, planning, monitors every single process. Some bullet points:

1) Apply APQP Product development analysis

2) Lay emphasis on prevention and planning

3) Quality Criteria (ISO and TS 16949)

Q3. How do you ensure on-time delivery?

1) Detailed planning, details per hour/person/machine number/stakeholder…

2) Main material is managed efficiently

3) Daily progress meetings, a recovery plan will be reviewed by the management team once any key chain is a delay.

4) If a delay happens on delivery in the course, extras hours will help to turn it on schedule

Q4. How can you if we don’t have the CAD data?

Gennki is able to generate the CAD for your review and approval in terms of your 2D sketch, or certain samples.

Q5. Can we test the plastic injection mold?

You are always welcome to company with us to try the molds in place in person. The testing video can be supplied for your checking with your absence.

Q6. How long does an injection mold last?

Generally, a plastic injection mold could complete anywhere between 100,00 to 1 million (or sometimes somewhat more than a million) cycles in its lifetime, so it's subject to customer’s expectancy.

Q7. How about your guarantee or aftersales?

The worn-easily spare parts will be freely provided during the warranty period. Gennki’s strategic associated American mold shop will assist you to handle the modification change if needed after the delivery.

Q8. How Can I visit your company from abroad?

Easy to find, you may take an international flight either land at PVG Airport or Hongqiao Airport from your workplace. The nearby high-speed train station to Hongqiao Airport will facilitate your trip to elsewhere in China.

|