| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Shutter Door Roll Forming Machine |

|---|---|

| Brand Name: | Sussman |

| Model Number: | SM-OP |

| Certification: | CCC, SGS, ISO9001, CE |

| Place of Origin: | Wuxi Jiangsu China |

| MOQ: | 1 set |

| Price: | negotiable |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram, D/P |

| Supply Ability: | 10 sets per month |

| Delivery Time: | 75days |

| Packaging Details: | Standard packing |

| Speed: | 5-6m/min,30m/min |

| Thickness: | 0.4mm-0.8mm |

| Motor Power: | 7.5KW or 11KW |

| Forming Roller: | about 20 Stations |

| Driven: | Gear Box Driven |

| Cutting: | Servo Following Saw Cutting |

| Company Info. |

| Sussman Machinery(Wuxi) Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

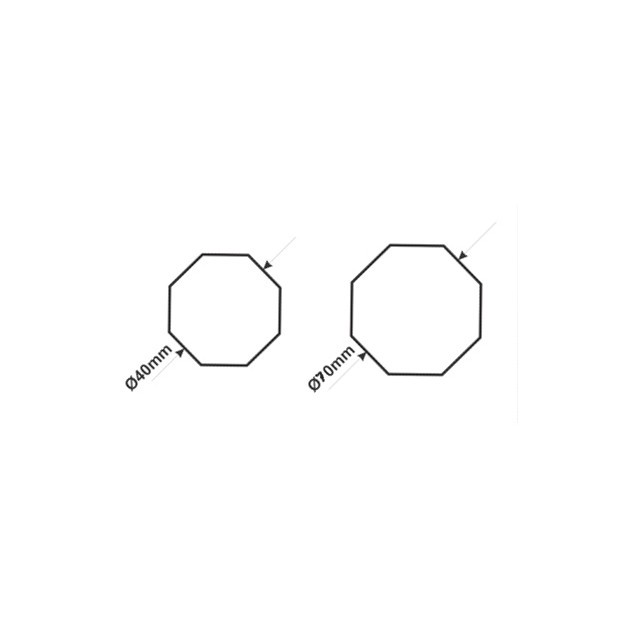

40mm 50mm 60mm 70mm Octagonal Pipe Roll Forming Machine with Servo Following Cutting

Octagonal tube is accesory of shutter slat door. Normally we can

make size 40mm, 50mm,60mm,70mm. Also we customized the size as the

client's requirement.

Normally one roll forming machine produce one size of octagonal

tube. If you want to produce more size in one machine, we recommend

cassettes to achieve profile change, they share one machine frame,

save more space.

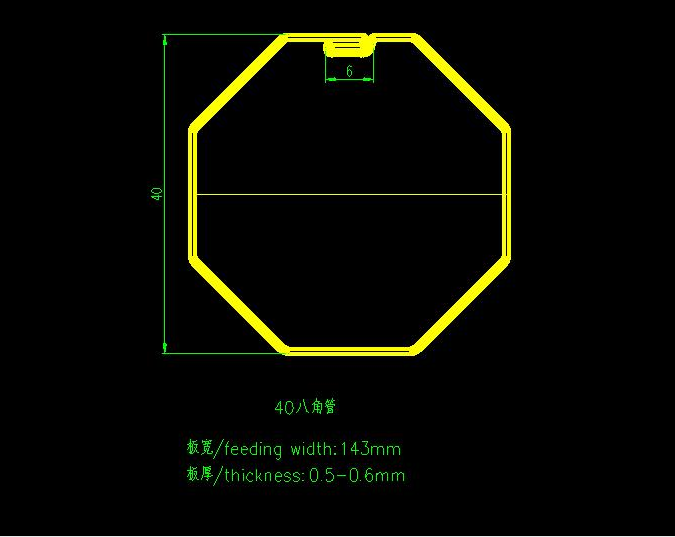

Technical Parameter

Machine specification:

Forming thickness 0.5-0.6 galvanized coils

Forming speed: About 5-6 M/min (EXCLUDING CUTTING STOP TIME), the speed can reach 10m/min if you do not need the punching

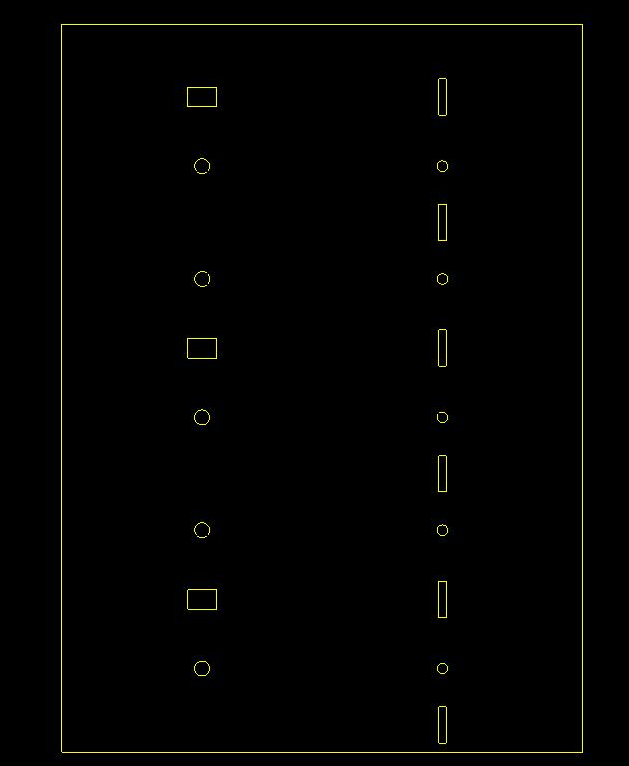

Forming roller: about 20 stations

Main motor power: 7.5KW

Roller material: 45# forged steel, surface coated with chrome

Main shaft material: 45# steel

Main axis dia.: ¢50mm

Hydraulic cutting pressure: 10-12Mpa

Cutting method: hydraulic powered, cutting after roll forming.

Cutting blade material: Cr12 quenching treatment

Electrical controlling system: Whole line adopted PLC control, cut to length tolerance≤2mm

Water cooling system

Main Components

| Serial No. | Commodity & Description | Quantity |

| 1 | 3T manual uncoiler | 1 set |

| 2 | feeding guiding | 1 set |

| 3 | Main roll forming machine | 1 set |

| 4 | Output table | 1 set |

| 5 | Main drive gear box | 1 set |

| 6 | Fly saw cutting | 1 set |

| 7 | Controlling system (including cabinet) | 1 set |

| 8 | Water cooling system | 1 set |

1. Reasonable Price

2. High Quality

3. 12 Months Warranty

4. More Than 10 Years Experience

5. Durable

6. Reliable

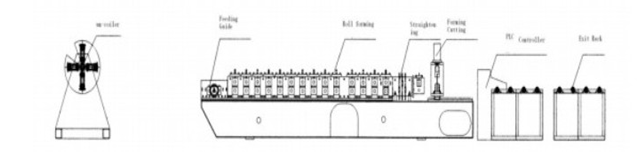

Working Flow

Decoiler—→feedingwithguide—→main roll forming machine—→fly saw cutting—→ run out table

Forming Machine Pictures

Packaging & Delivery

Packaging Details:

1.Tighten to container with steel wire rope and welded angel iron.

2.Main forming machine and uncoiler is naked (if you need we can

also packed with water-proof plastic)

3.Roll forming machine PLC control system and moter pump are packed

with water-proof plastic coverage.

Delivery Detail: 75 days after your pre-deposit

Our service

1. Professional mechanical background sales for better undestanding

customer's need

2. Experienced in China machine industry for supplying

comprehensive machines and equipments

3. Strictly product manufacturing and quality controlling to ensure

every machine we sold is satisfied with our customer

4. Engineers available to service machine overseas, for example

installation, training, etc

5. Lifelong service for spares, ware parts, technical supporting,

etc

|