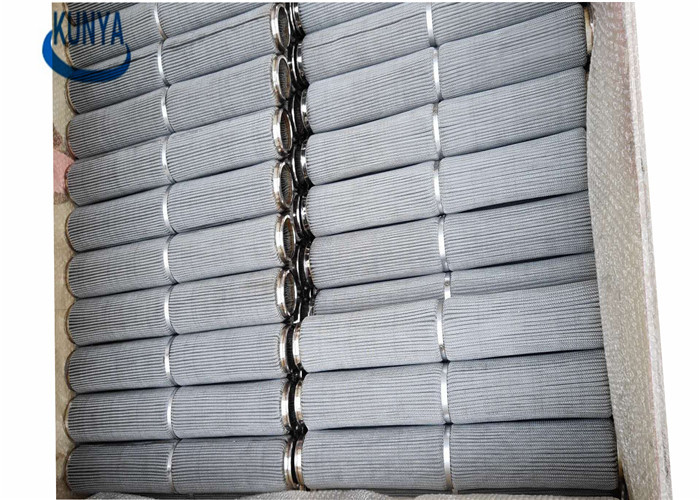

metal felt filter media is made with thin filaments of nonwoven

stainless steel. These porous metal felt filter elements are ideal

for high pressure, highly corrosive, highly viscous or radioactive

applications. They feature extremely high porosity (up to 85%),

high flow rates (up to 20 times higher than other media types), and

very long life.

These elements are the same we use in our

high pressure filter assemblies, which are often employed in highly challenging applications.

Random fiber filtration (metal felt) can provide absolute particle

retention, longer on stream time and high dirt-holding capacity for

under 60 micron filter elements. Although more expensive, it oftens

offers clear advantages over wire cloth, sintered metal or

non-metallic fibers. Its high temperature, high pressure and

corrosion resistance combined with almost unending cleanability,

make it highly economical for hostile environments.

Metal Felt Filter Element Specifications

Metal felt filter elements have a random matrix of 316-L stainless

steel filaments with diameters from 4 to 25 microns. The finer the

micron, the more open area is provided in a pure crosshatch

pattern. When sinter bonded, this random matrix can provide:

- Extremely high porosity (up to 85%)

- high flow rates: up to 20 times higher than other media types

- long on-stream lifetime

- downscaling is possible (less filter surface is needed to filter

the same volume)

- Low pressure drop: The high porosity of our metal fiber media allows a very low

pressure drop (and thus lower energy cost), even at high filtration

velocities

- Ease of cleaning: The open structure of porous metal media allows you to clean in

situ by backpulsing or backwashing

- High strength: The sintering process creates strong fiber bonds and guarantees a

high strength filter medium. Combined with an appropriate inner

core, our filter elements can withstand thermal shock, high

pressures, and frequent backpulsing.

- Heat & corrosion resistance: Our filter media can be used in high temperature (up to 1000° C,

depending on the alloy) and/or corrosive applications - where

non-metallic textile, ceramic or polymer products fail

- Can be used for surface or depth filtration. Our filter media enables you to achieve high efficiencies through

a cake build-up (surface filtration) and also offer high dirt

holding capacity for depth particles capture (depth filtration)

- Stainless steel and other alloys available: not brittle, chemical cleaning is possible, weldable, low thermal

expansion, maintains structure (no thermal shock) Depending on the

performance you require, we select the proper alloy to provide the

required resistance and strength

For filtration, the absolute filter ratings are:

- for liquids — 1 to 80 µm

- for air & gases — below 0.1 µm is possible (HEPA, ULPA)

Metal Felt Filter Element Applications

- Polymer filtration: polyaramides, polyesters, polypropylene, polyamide,

- Spinning polymers

- Automotive:

- air filters

- lubricant filters

- filters for air bag inflators

- Chemical and catalyst recovery

- High-temperature liquids

- Cryogenic fluids

- Solvents, ketones, esters, liquid hydrocarbons

- Feed water and make-up water

- Ethylene glycol

- High-efficiency solids recovery or liquid recycling