| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Atlas G Series |

|---|---|

| Brand Name: | Atlas |

| Model Number: | G15~26 |

| Certification: | ISO 8573-1 CLASS 0 |

| Place of Origin: | China |

| MOQ: | 5pcs |

| Price: | be negotiabled |

| Payment Terms: | L/C, T/T, D/A, Western Union, D/P |

| Supply Ability: | 100pcs per month |

| Delivery Time: | 7~30days |

| Packaging Details: | Atlas standard packing |

| Machine Type: | Oil Injected Screw air compressor |

| Model: | G15~26 |

| Motor: | IE3 Premium motor |

| Frequency: | 50~60Hz |

| Motor Power: | 15~26kw |

| Working Pressure: | 7.4~12.8 bar |

| Company Info. |

| CEBE GROUP HK CO.,LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

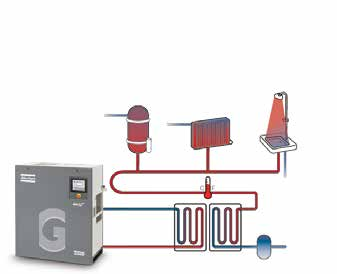

Compact Screw Compressor G Series 15~26kw Atlas Rotary Oil Injected

7.4-12.8bar Working Pressure

Click to open our catalog:G2-90 wuxi leaflet EN 2935081343.pdf

Compact Economical Compressors G15/G18/G22/G26

Premium GA quality and optimal serviceability at the lowest initial

investment.

• Good-quality, dry air thanks to the integrated dryer.

• Total control and assured efficiency with the Elektronikon ®

controller.

Set to tackle your daily challenges, Atlas ’s high-performance GA compressors beat any workshop solution. Ready to supply high-quality air, they keep your air network clean and your production up and running.

Robust element & motor

• The GA 15-26’s compression element, the most used in its size, is

combined with an IE3/NEMA Class 1 efficiency motor.

• A 2-3% higher efficiency with the gear-driven drive train

compared to belt-driven systems.

• Gear-driven drive train for best-in-class reliability and limited

maintenance.

Advanced monitoring

• State-of-the-art monitoring using a simple Ethernet connection,

thanks to the Elektronikon ® with a built-in server.

• Service and warning indications, error detection and compressor

shut-down.

• Optional Elektronikon ® graphic controller for further enhanced

remote monitoring features and service time indications.

High-tech oil vessel

• Protection from oil contamination: extremely low oil carry-over

thanks to the vertical design of the oil vessel.

• Extremely low losses of compressed air during load/unload cycle

thanks to minimized oil vessel size.

Integrated quality air solutions

• The integrated dryer avoids condensation and corrosion in the

network. Optional filters for air quality up to ISO Class 1 level

(<0.01 ppm).

• Standard included water separator.

• Additional energy savings with the dryer’s no-loss electronic

drain.

Easy installation

• A true plug-and-play solution, ideal machine for installation

companies and OEMs.

• Optional integrated dryer.

• Easy transportation by forklift.

• Remarkably compact footprint.

Specifications

| COMPRESSOR TYPE | Pressure variant (bar) | Max. working pressure WorkPlace | Capacity FAD* | Installed motor power | Noise level** | Weight WorkPlace | Weight WorkPlace Full Feature | |||

| bar(e) | psig | l/s | m³/min | cfm | kw | dB(A) | kg | kg | ||

| G15 | 7.4 | 7.4 | 107 | 47.1 | 2.83 | 99.8 | 15 | 66 | 421 | 474 |

| 9.1 | 9.1 | 132 | 42.4 | 2.54 | 89.8 | 15 | 66 | 421 | 474 | |

| 10.8 | 10.8 | 157 | 39.2 | 2.35 | 83 | 15 | 66 | 421 | 474 | |

| 12.5 | 12.5 | 181 | 30.3 | 1.82 | 64.2 | 15 | 66 | 421 | 474 | |

| G18 | 7.4 | 7.4 | 107 | 56.9 | 3.41 | 120.5 | 18 | 68 | 431 | 495 |

| 9.1 | 9.1 | 132 | 50.8 | 3.05 | 107.8 | 18 | 68 | 431 | 495 | |

| 10.8 | 10.8 | 157 | 48 | 2.88 | 101.7 | 18 | 68 | 431 | 495 | |

| 12.5 | 12.5 | 181 | 42.2 | 2.53 | 89.4 | 18 | 68 | 431 | 495 | |

| G22 | 7.4 | 7.4 | 107 | 67.7 | 4.06 | 143.3 | 22 | 69 | 440 | 495 |

| 9.1 | 9.1 | 132 | 60.6 | 3.64 | 128.4 | 22 | 69 | 440 | 495 | |

| 10.8 | 10.8 | 157 | 54.4 | 3.26 | 115.2 | 22 | 69 | 440 | 495 | |

| 12.5 | 12.5 | 181 | 49 | 2.94 | 103.8 | 22 | 69 | 440 | 495 | |

| G26 | 7.4 | 7.4 | 107 | 74.4 | 4.46 | 157.6 | 26 | 70 | 500 | 558 |

| 9.1 | 9.1 | 132 | 69.5 | 4.17 | 147.2 | 26 | 70 | 500 | 558 | |

| 10.8 | 10.8 | 157 | 62.8 | 3.77 | 133 | 26 | 70 | 500 | 558 | |

| 12.5 | 12.5 | 181 | 57.1 | 3.43 | 120.9 | 26 | 70 | 500 | 558 | |

* Unit performance measured according to ISO 1217, Annex C, Edition

4:2009.

Reference conditions:

• Absolute inlet pressure 1 bar (14.5 psi)

• Intake air temperature 20°C, 68°F

FAD is measured at the following working pressures:

• 7.5 bar versions at 7 bar

• 8.5 bar versions at 8 bar

• 10 bar versions at 9.5 bar

• 10.5 bar serion at 10 bar

• 13 bar versions at 12.5 bar

Applications

• Auxiliary or main heating of warehouses, workshops…

• Industrial process heating

• Water heating for laundries, industrial cleaning and sanitary

facilities

• Canteens and large kitchens

• Food industry

• Chemical and pharmaceutical industries

• Drying processes

|