| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Powder Packing Machine |

|---|---|

| Place of Origin: | Anhui, China |

| Brand Name: | Ewinall |

| Certification: | ISO9001:2008,CE |

| Packaging Details: | packed in wooden box |

| Supply Ability: | 5 sets per day |

| Model Number: | 25W |

| MOQ: | 1 set |

| Delivery Time: | 20 days |

| Type: | Filling Machine |

| Condition: | New |

| Application: | Food, Commodity, Chemical, Machinery & Hardware, Food/Chemical |

| Packaging Type: | Cartons, Bags, Pouch, case |

| Packaging Material: | Plastic, Wood |

| Automatic Grade: | Semi-automatic, Semi-Automatic |

| Driven Type: | Electric, Electric |

| Voltage: | 4N-AC380V |

| Dimension(L*W*H): | 2846*1025*2738 |

| Weight: | 400kg |

| After-sales Service Provided: | Online support, Video technical support |

| Warranty: | 1 Year |

| Color: | green and blue |

| Packing material: | PP/PE/woven bags |

| Packing speed: | 200-300bags/hour |

| packing range: | 2.5-15kg |

| Keyword: | coffee bean packaging machine |

| Material: | SS304 |

| Division value: | 2-10g |

| Port: | Any main port |

| Company Info. |

| Anhui Yongcheng Electronic and Mechanical Technology Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

wheat flour powder small packing machine

DCS-25W series electronic quantitative powder packaging scale

A:Scope of application

Quantitative packaging of powder materials in flour, feed, food additives, chemical industries and other industries.

B:Features

1. The domestically pioneered conveyor manual lifting technology,

the core components adopt internationally renowned brands, advanced

functions, stable and reliable.

2. The specially designed twisted-pair cage feeding mechanism,

combined with the control algorithm of the controller, makes the

scale's packaging speed and accuracy high.

3. Adopt international advanced high-precision weighing sensor and

quantitative controller, the controller adopts high-performance A/D

converter, the conversion rate is up to 200 times/sec, the input

sensitivity is 0.5μν/d, the measurement accuracy is high, and the

stability is good.

4. Equipped with manual control mode, which can control the

discharging and loose bag mechanism separately by manual operation,

which is convenient for cleaning agglomerated and clogged

materials.

5. It has the functions of automatic statistics, printing and data

communication of the number of packages and the volume of packages.

6. With automatic drop correction function. Out of tolerance alarm.

7. The operation is simple. The operator only needs to cover the

bag and touch the bag clamping switch (or step on the foot switch),

and the feeding, filling, unloading and other actions are all

automatically completed.

C:Parameter:

| Model: | DCS-25W |

| Covveyor: | lifting conveyor |

| Display: | intelligent controller |

| Range(kg) | 5~25 |

| Division(g) | 5 |

| Accurancy | X(0.5) |

| Capacity(bags/hour) | 170~240 |

| Consumption | 3.7kw,0.4-0.5Mpa Air16.7L/min |

| Environment | Humidity≤90%,4N-AC380V±10% 50HZ |

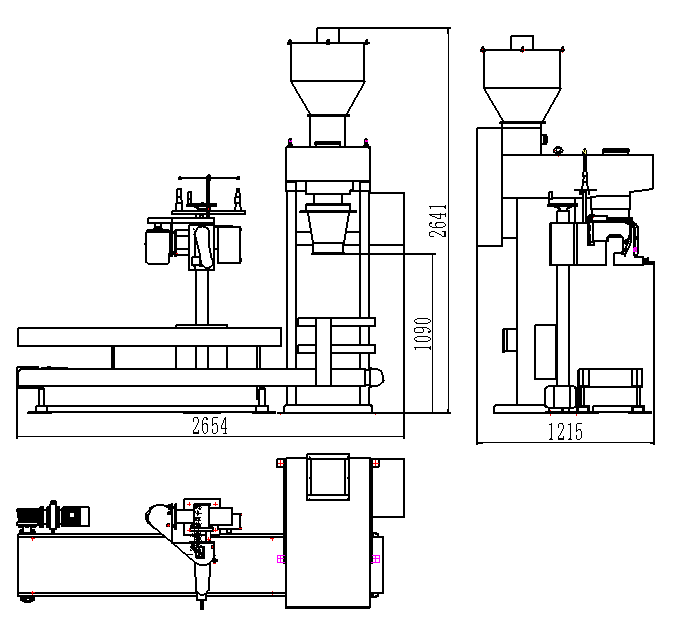

Dimension(mm) L×W×H | 2654×1215×2641 |

Remarks: The height of the external dimensions includes the hopper

D:Components

| Name | Brand | Note |

| Weighing controller | GM | Weighing control instrument product development and design is a Japanese company, and all components are imported from Japan. |

| PLC | DELTA | |

| Load cell | METLLER TOLEDO(USA) | |

| Solenoid valve | MINDMAN | |

| SENSOR | SICK(Germany) | |

| Proximity switch | OMRON(Japan) | |

| Cylinder | AIRTAC | |

| Air part | AIRTAC |

E:Certification

|