| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Biodiesel Production Equipment |

|---|---|

| Place of Origin: | China |

| Brand Name: | FOREVER |

| Model Number: | Decisions based on user needs |

| Packaging Details: | According to the actual situation decision |

| Supply Ability: | 10000 Unit/Units per Day Delivery period is determined by the number of products and requ |

| Price: | $20,000.00/Square Meters |

| Application: | Distillation |

| Power Source: | Water, electricity, natural gas |

| Process: | Vacuum Distillation |

| Power: | According to the actual situation decision |

| Dimension(L*W*H): | According to the actual situation decision |

| Warranty: | 12months |

| martical: | According to the actual situation decision |

| After-sales Service Provided: | Engineers available to service machinery overseas |

| LAN: | According to the actual situation decision |

| Processing Method: | New |

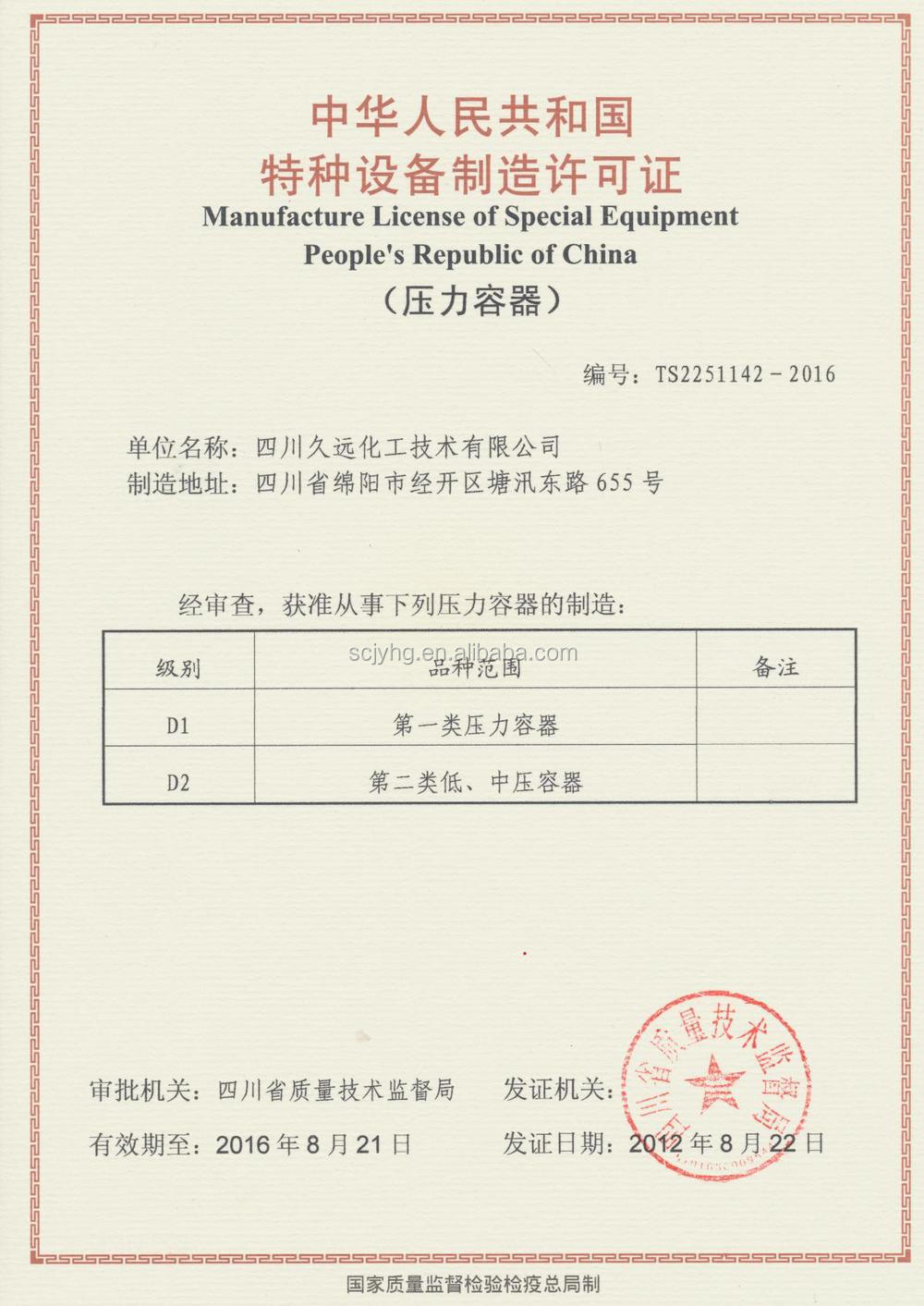

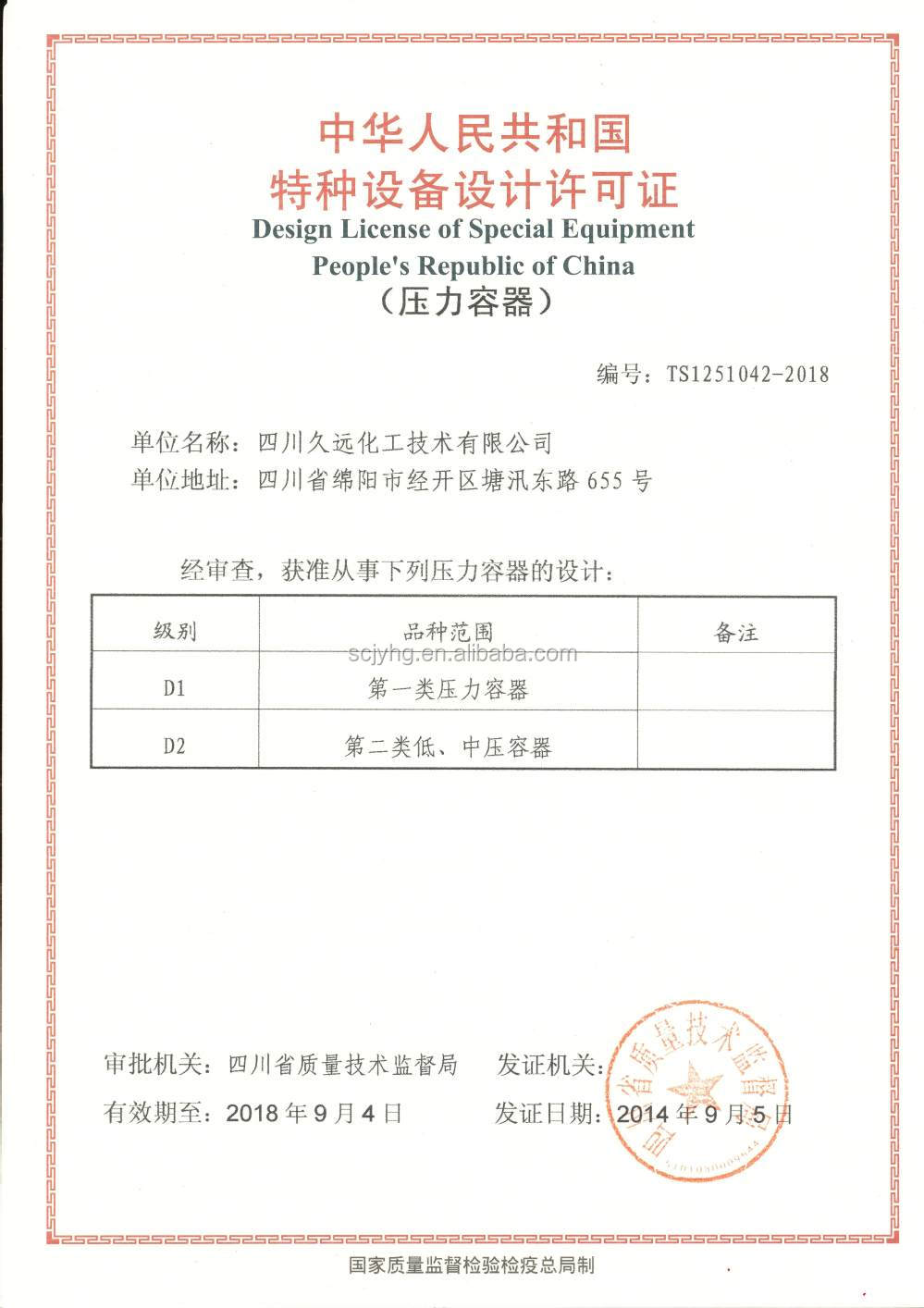

| productivy: | esign license of special equipment |

| Product name: | Bio-diesel plant |

| Renewable energy: | Use oil as a raw material of plant or animal oils and fats |

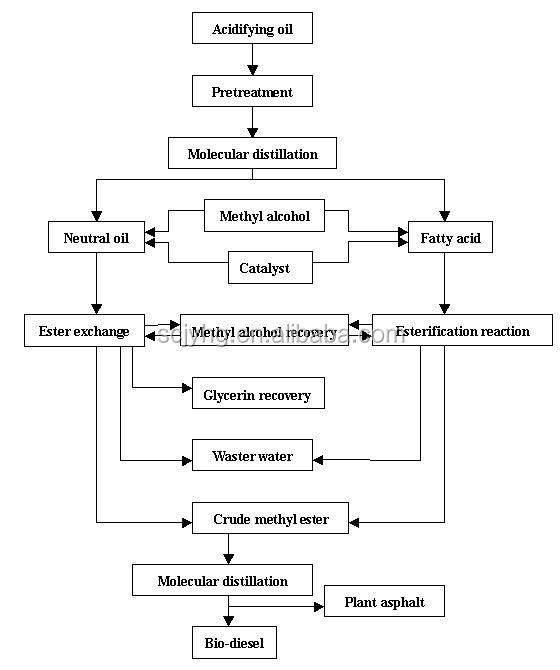

| Routing: | Acid-catalyzed, base-catalyzed |

| Refined crude methyl ester: | Multi-stage molecular distillation |

| Engineering experience: | China, Vietnam, Malaysia and so on |

| Port: | chongqing,shanghai |

| Company Info. |

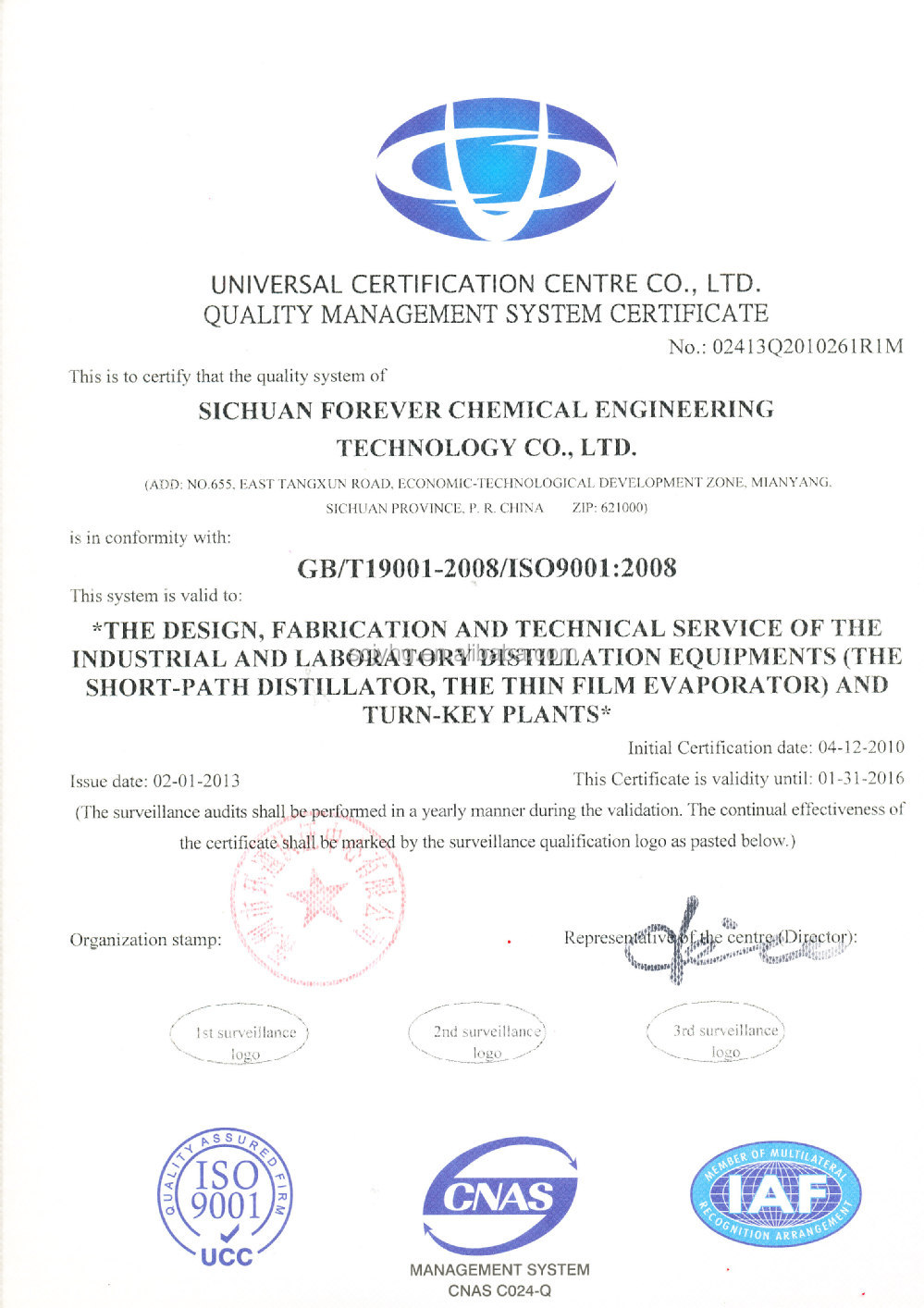

| Sichuan Forever Chemical Engineering Technology Co.,Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

The technique has widely used in all kinds of raw materials. Theproduct is high quality and yield percentage. It is environment caredand energy saved.

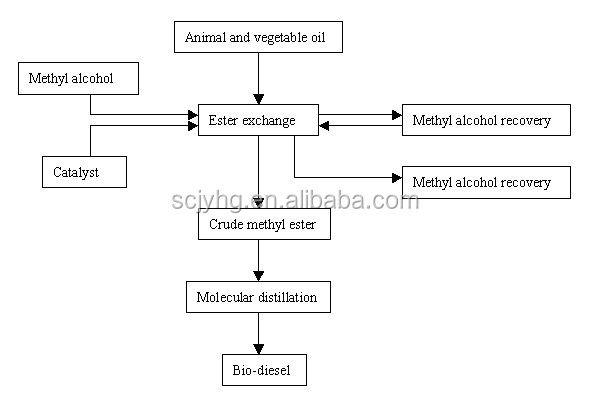

2. The technology of producing bio-diesel by animal / vegetable oil

Animal/vegetableoil is a high-quality oil and fat. It includes few

free fatty acid (thecontent is little than 2%). It can gain crude

methyl ester and itsby-product crude glycerin by ester-exchange

reaction of adding methylalcohol and alkalescene catalyst. It can

gain bio-diesel after crudemethyl ester is distilled by short-path.

After the crude glycerin ispretreatmented, short-path distilled, it

can gain glycerin used inindustry and medicine.

Thetechnique is the same with high-quality raw material

ofanimal/vegetable oil. The product is high quality and yield

percentage.It is environment cared and energy saved.

In the rancidity oil, some oil and fat is ranciditied, so there issome free fatty acid. At first, the acid catalytic reaction is adapted,then adopt alkalinous catalytic reaction after the free fatty acidreacted completely. The free fatty oil become methyl ester after addingpyro alcohol and concentrated sulfuric acid under definite temperature(65~68℃). After the reaction of methyl ester, the sodium methylate ismade of pyro alcohol and NAOH. It can gain fatty acid methyl ester andit's by-product glycerin after the fat and oil and measurable pyroalcohol ester exchanged by the alkalinous catalyst of sodium methylateunder definite temperature (65~68℃).

Projects

Meet the requirements of overseas export goods packaging

|