| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Tungsten Alloy Products |

|---|---|

| Brand Name: | JINXING |

| Model Number: | customized |

| Certification: | ISO 9001 |

| Place of Origin: | CHINA |

| MOQ: | 10 pcs |

| Price: | Negotiable |

| Payment Terms: | T/T, L/C, Western Union, D/A |

| Supply Ability: | 2000 kg per month |

| Delivery Time: | 15-20 days |

| Packaging Details: | plywood cases |

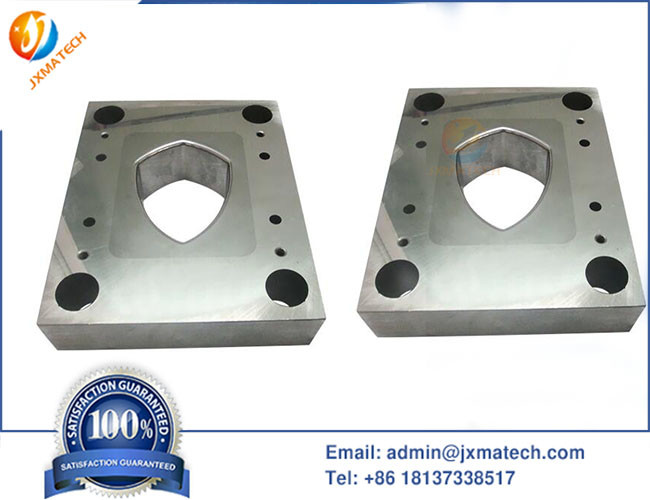

| Product name: | Tungsten Carbide Moulds For Punching And Forging Tool |

| Hardness: | 57-62 HRC |

| Electric discharge processing precision: | 0.03mm |

| Advantage: | Control Quality |

| Application: | Punching/forging/stamping/drawing/nut forming dies |

| Grade: | YG-8 |

| Standard: | ASTM B578-2011 |

| Company Info. |

| JINXING MATECH CO LTD |

| View Contact Details |

| Product List |

Tungsten Carbide Moulds For Punching And Forging Tool are made of tungsten steel. Tungsten steel is an alloy material made from refractory metals and hard compounds that bond metals through powder metallurgy. Tungsten steel has good wear resistance, high hardness, high toughness, high strength, heat resistance and corrosion resistance and a series of excellent properties. In particular, it has higher hardness and better wear resistance. It maintains the same performance even at 500°C. It still has high hardness and toughness at 1000°C.

| Grade | Int'l Grade | Density | Hardness | Bending strength | Application |

| YG8 | K30 | 14.8 | 89.5 | ≥3500 | It is applicable to high strength, impact resistance and earthquake resistance. It is suitable for making forming knives and wear-resistant parts. |

| YG11 | K40 | 14.4 | 88.5 | ≥3650 | It is suitable for making stamping abrasives. |

| YG15 | K40 | 14 | 87.5 | ≥3800 | It is suitable for making stamping die (processing silicon steel sheet), wear-resistant and consumable parts, etc. |

| YG20 | / | 13.5 | 85.5 | ≥4200 | It has high strength. It is suitable for making stamping dies such as progressive die. |

| YG6X | K10 | 14.9 | 91.5 | ≥3200 | It is a fine-grained alloy with good wear resistance. It is suitable for making forming knives and wear-resistant parts. |

| YL10.2 | K10 | 14.5 | 92 | ≥3850 | It is an ultra-fine particle alloy with high wear resistance, bending strength, adhesion resistance and pad strength. Suitable for low speed rough machining. |

Tungsten Carbide Moulds Picture:

1. Corrosion resistance and wear resistance

2. High pressure resistance, long service life

3. Impact resistance and wear-resistant alloy products

4. High precision, can be customized according to the drawings

|