| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Aluminum Holding Furnace |

|---|---|

| Brand Name: | Hydeb |

| Model Number: | HD500 |

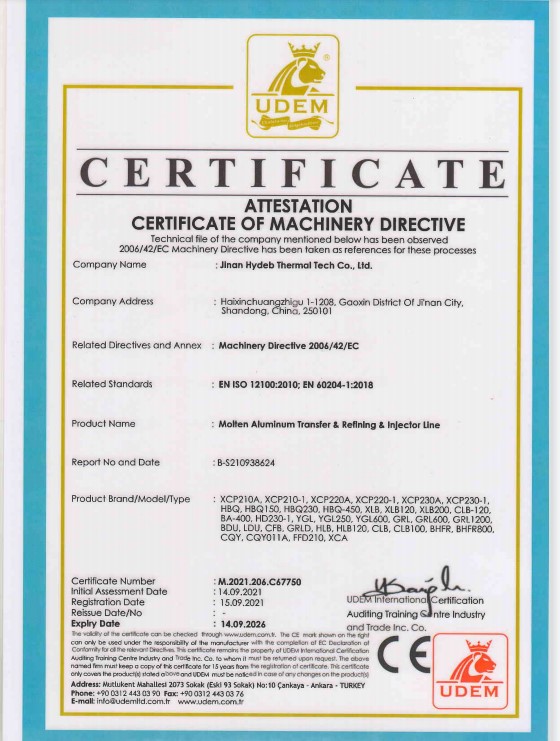

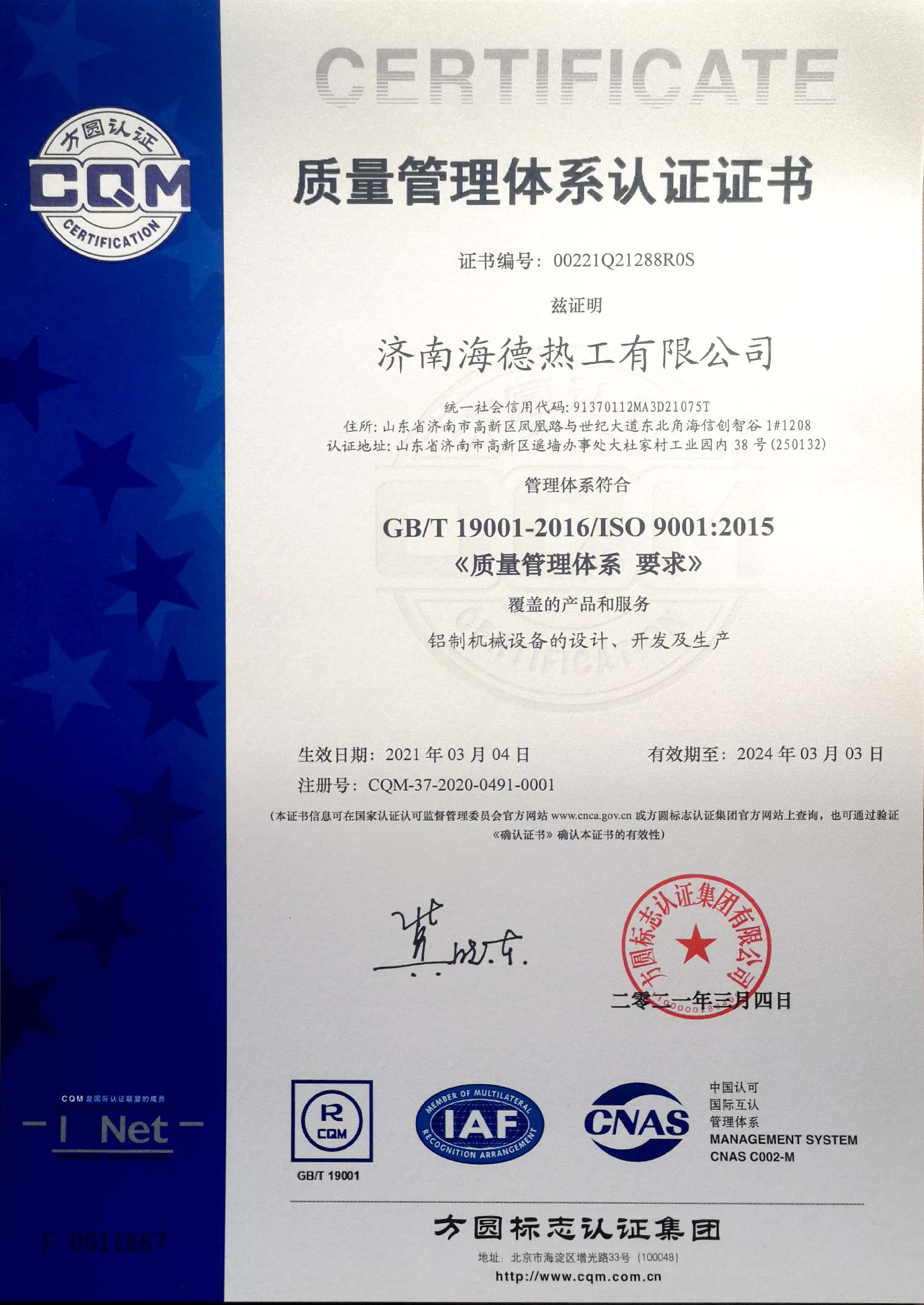

| Certification: | CE,ISO9001,ISO14001,IS45001,High-tech Enterprise,Intellectual Property,Patents |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | $ 50000-$100000/set |

| Payment Terms: | T/T |

| Supply Ability: | 20 sets per year |

| Delivery Time: | 50 working days |

| Packaging Details: | Wooden Case or Pallet |

| Key Words: | Dosing Holding Furnace 500KG Siliver Aluminum Alloy Die Casting Peripheral Furnace |

| Dosing accuracy: | <± 1.5% |

| Material: | Iron Steel & Insulation layer |

| Colour: | Siliver |

| Capacity: | 500KG |

| Warranty time: | 1 Year |

| Function: | Pouring molten aluminum |

| Size: | Standarded |

| Company Info. |

| Jinan Hydeb Thermal Tech Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Dosing Holding Furnace 500KG Siliver Aluminum Alloy Die Casting Peripheral Furnace

Aluminum Alloy Die Casting Peripheral Dosing Holding Furnace

1. Application

The dosing holding furnace is mainly used for maintaining temperature of

molten aluminum and fixed supply of aluminum during aluminum die casting.

For the furnace, aluminum is supplied by gas pressurization and an

expert-based dosing calculation procedure is adopted, realizing the

quantification of aluminum supply and high-efficiency production. The

furnace is a new-type holding furnace manufactured by the company using

our self-developed “dosing control technology” based on years of

experience in producing low pressure holding furnaces and automatic liquid

surface compression systems.

2. Features

• The molten aluminum outflows from the lower part of the molten pool, not mixed with oxidation slags on its surface.

• High dosing accuracy, the dosing accuracy<± 1.5% (by weight).

• The furnace is closed heating, minimizing the oxidation loss of molten aluminum to≤0.1%.

• The molten aluminum is of high quality owing to less hydrogen absorbed.

• The high consistency of casting weight, casting flow rate,

casting speed, casting temperature and casting time

and other parameters prevents various casting factors from

affecting casting quality.

• It can be equipped with an in-line air brick degassing and

refining device to continuously provide high-quality molten

aluminum.

3. Parameter Data

| Furnace bath capacity | 500 Kg (AL) |

| Single aluminum tapping volume | 1-150 kg |

| Dosing accuracy | <± 1.5% |

| Maximum allowable pressure | 0.20 MPa |

| Rated temperature of furnace chamber | 900℃ |

| ontrol precision of molten aluminum temperature | ±2℃ |

| Molten aluminum heating rate | ≥0.5℃/min |

| Temperature rise in the furnace shell surface | ≤45℃ |

4. Pictures

5. Our Certification CE, ISO

6. Our Clients

|