Laser Rotary Pneumatic Chuck For Professional Laser Tube Cutting

Machine

1. Descripition

Our pneumatic chuck is mainly designed for laser tube cutting

machine. Pneumatic chuck is applied to clamp and loosen tubes and

feed tubes when cutting tube. Except round tubes, our pneumatic

chuck can also clamp rectanbular, square, H-shape and L-shape

tubes.

It is used base point positioning and it is convenient for the

adjustment of the main quipment and greatly shortens the debugging

time of the main equipment. And our design is full stroke design.

There's no need to adjust the jaw, it is easy to clamp and

centering, to achieve switching different pipe diameters, which

greatly saving clamping time.

The pneuamtic chuck can work in full stroke without additional

adjustment of four jaws.Adopting a fully closed structure, the

chuck has better stability and wear resistance.It has longer

service life, higher rotary accuracy and repeated positioning

accuracy becaused of the inner cross roller bearing. This pneumatic chuck is widely applied to

professional pipe cutting machine and other pipe processing machine

system.

2. Performance Parameters

| G500DC-230 |

| 220mm |

| 1.5KN |

| 0.3-0.9MPa |

| 150r/min |

| 8-228mm |

| 315mm |

| 4.18Kg.m2 |

| 124kg |

| 245kg |

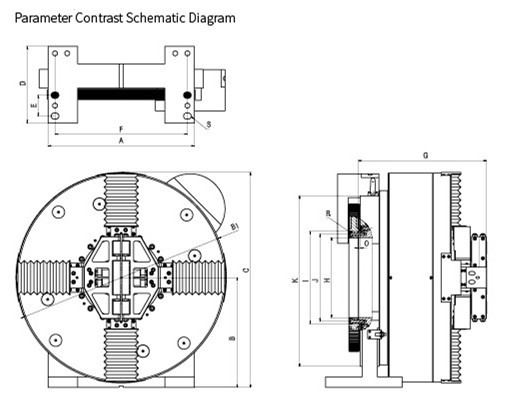

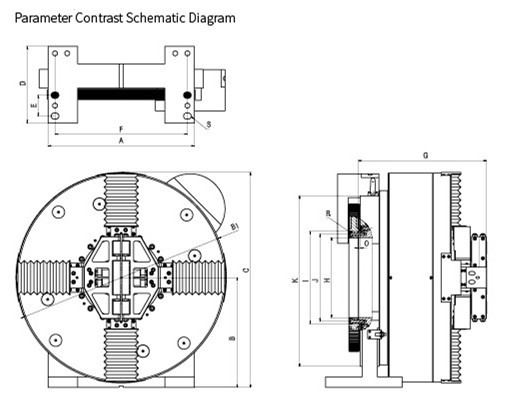

3. Dimensions

| Specifications | A | B | B1 | C | D | E | F | G | H | I | R | S |

| G500DC-230 | 420 | 315 | 600 | 615 | 220 | 60 | 380 | 368 | 230 | 265 | 12-M8 | 18X22 |

4. Advantages

| a. Full stroke design |

| b. Wide range of applications, diversification of processing

profiles |

| c. High repetitive positioning accuracy |

| d. Low maintenance cost, long service life |

e. Multiple configurations are available

e. 1 Solid or hollow

e. 2 Comb-type or mortise-groove type claws |

5. Production Line