| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

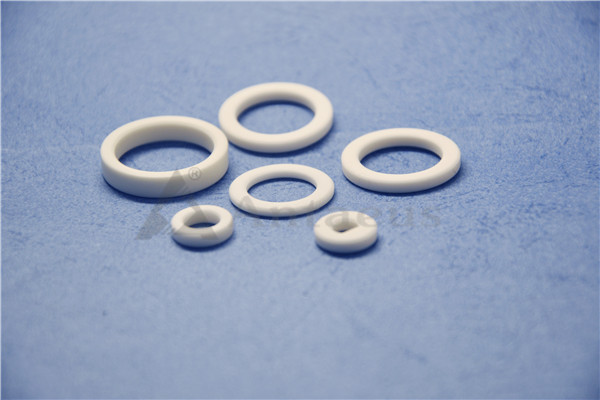

| Categories | Alumina Ceramic Rings |

|---|---|

| Brand Name: | Antaeus |

| Model Number: | AD-B030 |

| Certification: | / |

| Place of Origin: | Hunan,China |

| MOQ: | Negotiation |

| Price: | Negotiation |

| Payment Terms: | T/T or Negotiation |

| Supply Ability: | Full Supply |

| Delivery Time: | 15-45 days |

| Packaging Details: | Inner vacuum packaging, outside carton. |

| Product Name: | Metallized Alumina Ceramic Rings / Ceramic Insulators for Battery |

| Material: | Alumina (Aluminum Oxide, Al2O3) |

| Insulation Resistance: | 1000M Ω(1000VDC) |

| High Light: | Alumina Ceramic Rings / Metallized Ceramic Insulators / Electrical Ceramic Components |

| Thermal Shock Resistance room temperature to 850C: | will not burst or leak after five operations |

| Max. Use Temp.: | 1650℃ |

| ROHS Hardness: | ≥89 |

| Flexural strength: | 550 Mpa(psix10^3) |

| Compressive Strength: | 2600(377) Mpa(psix10^3) |

| Coefficient of thermal expansion: | 8.2 X10^-6/℃ |

| Coefficient of thermal conductivity: | 17-30.4 W/m.K |

| Company Info. |

| Loudi Antaeus Electronic Ceramic Co.,Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Alumina Seal Ceramic Rings / Industry Insulation Rings

1. Description:

2. Feature Advantages:

1) Refractory, High Temperature Resistance, Maximum Used

Temperature: 1800 ºC (3272ºF)

2) Hardness Strength, Wear Resistance Up To Mohz 9.0 ; HRA 80-90

3) High Voltage, Good Insulation Performance ,Electrical

Resistivity Up To 10∧14 Ohm.Cm

4) High Polished Surface Up To Rz0.8(Ra0.1)

5) Superior Mechanical Strength, MAX 10 MPa.m1/2 Fracture toughness

6) Pressure Resistance, Max 2300MPa compressive strength

7) Anti-High Corrosion Resistance, Such As Acid Alkali Resistance

8) Long Service Life

3. Material Features / Properties:

| Color | White or Ivory | White or Ivory | White or Ivory | |

| Density | g/cm 3 | 3.82 | 3.9 | 3.92 |

| Hardness | HRA | 83 | 85 | 85 |

| Flexural Strength | Mpa (psi*10 3 ) | 375 | 386 | 381 |

4. Technical Parameters:

| Technical Parameters of Ceramics | ||||||||

| Items | Test Conditions | Unit or Symbol | 99% AL2O3 | 95% AL2O3 | 90% AL2O3 | Zirconia | Steatite | Silicon Carbide |

| Volume Density | -- | g/cm3 | ≥3.70 | ≥3.62 | ≥3.40 | ≥5.90 | ≥2.60 | ≥3.08 |

| Tightness | -- | Pa·m³/s | ≤1.0×10-11 | ≤1.0×10-11 | ≤1.0×10-11 | - | - | - |

| Liquid Permeability | -- | -- | Pass | Pass | Pass | Pass | - | |

| Flexural Strength | - | MPa | ≥300 | ≥280 | ≥230 | ≥1100 | ≥120 | ≥400 |

| Elastic Modulus | - | GPa | - | ≥280 | ≥250 | ≥220 | - | 400 |

| Poisson Ratio | - | - | - | 0.20~0.25 | 0.20~0.25 | - | - | - |

| Thermal Shock Resistance | 800℃( Room Temperature) Cycle: 10 times | Pass | Pass | Pass | - | - | - | |

| Coefficient of Linear Expansion | 20℃~100℃ | ×10-6 K-1 | - | - | - | ≤8 | - | |

| 20℃~500℃ | ×10-6 K-1 | 6.5~7.5 | 6.5~7.5 | 6.5~7.5 | 6.5~11.2 | - | - | |

| 20℃~800℃ | ×10-6 K-1 | 6.5~8.0 | 6.5~8.0 | 6.3~7.3 | - | 4 | ||

| 20℃~1200℃ | ×10-6 K-1 | - | 7.0~8.5 | - | - | - | - | |

| Coefficient of Thermal Conductivity | 20℃ | W/(m·k) | - | - | - | - | - | 90~110 |

| 1000℃ | ||||||||

| Dielectric Constant | 1MHz 20℃ | - | 9.0~10.5 | 9.0~10 | 9.0~10 | - | ≤7.5 | - |

| 1MHz 50℃ | - | - | 9.0~10 | - | - | - | - | |

| 10GHz 20℃ | - | 9.0~10.5 | 9.0~10 | 9.0~10 | - | - | - | |

| Volume Resistivity | 100℃ | Ω·cm | ≥1.0×1013 | ≥1.0×1013 | ≥1.0×1013 | - | ≥1.0×1012 | - |

| 300℃ | ≥1.0×1013 | ≥1.0×1010 | ≥1.0×1013 | - | - | - | ||

| 500℃ | ≥1.0×109 | ≥1.0×108 | -- | - | - | - | ||

| Disruptive Strength | D.C | kV/mm | ≥17 | ≥15 | ≥15 | - | ≥20 | - |

| Chemical Durability | 1:9HCl | mg/c㎡ | ≤0.7 | ≤7.0 | - | - | - | - |

| 10%NaOH | mg/c㎡ | ≤0.1 | ≤0.2 | - | -- | - | - | |

| Grain Size | - | μm | - | 3~12 | - | - | - | - |

5. Process Flows:

Formulating --- Granulating --- Forming --- Sintering --- Grinding --- Printing --- Nickel Plating --- Assembing --- Brazing --- Inspecting --- Packing

6. Production Facilities: Prilling Tower , Forming Machine , High Temperature Sintering Kiln

7. Detection Devices:

Electric Performance Tester , Film Thickness Analyzer , Granulometer , Helium Mass Spectrometer Leak Detector , Universal Pull Force Meter

8. Our advantages: Quality Assurance ; Price Competitive ; Factory Supply Directly ; Good Service

9. Shipping and Package:

10. Our aimed market:

Notes:Above information only for reference and please contact with us for more details freely when you have any inquiry!

|