| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Rubber Tile Making Machine |

|---|---|

| Brand Name: | HHS |

| Model Number: | XLB-550X550X4 |

| Certification: | CE/ISO |

| Place of Origin: | CHINA |

| MOQ: | 1 set |

| Price: | USD:8000-20000 /SET |

| Payment Terms: | D/A, L/C, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 80 sets/month |

| Packaging Details: | wood package/20-40 gp |

| Heating Platen Size: | 1000*1000 |

| Mold Closing ForceF: | 100T |

| Working Layers: | 1 |

| Motor Power: | 5.5KW |

| Overall Dimension: | 2200X900X2200mm |

| Weight: | 9000KG |

| Type: | Vulcanizer,tile Machine |

| Color: | Customizable |

| Power source: | Hydraulic |

| Usage: | rubber tile from waste tyre granule, glue, colour |

| Keyword: | tile vulcanizing press |

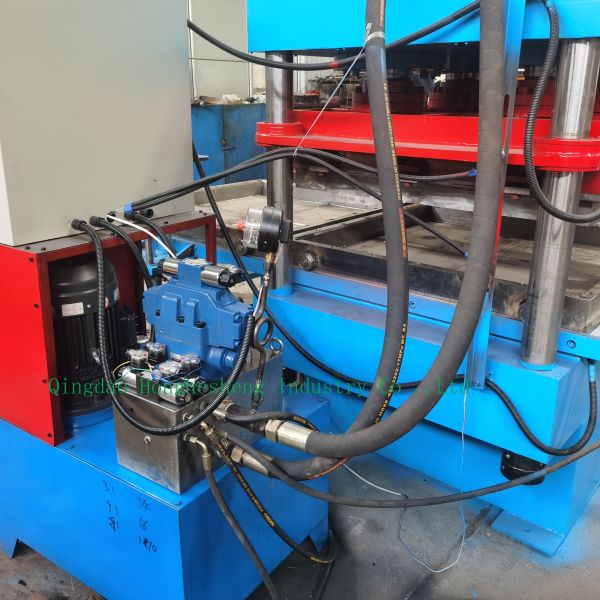

100T Rubber Tile Molding Machine/gym rubber tile machines/rubber floor tiles machine

Manual push-pull mold + High output and efficiency + Easy and safe operating

rubber flooring tiles product line is one type of environmental type rubber machine , used to process the waste tire rubber granules to be different types of rubber flooring tiles by vulcanizing and solidifying . Meanwhile , it can process PU granules , EPDM granules and nature rubber to be tiles .

Detailed Parameter

| Model | XLB-D1080*1080*1 |

| Unit Pressure | 10.3kg/cm² |

| Plate size (mm) | 1080*1080 |

| Daylight (mm) | 200 |

| Plunger stroke (mm) | 200 |

| Motor power (kw) | 5.5 |

| Cylinder Diameter | φ400mm |

| Cylinder Oil | φ200mm,4pcs |

| Pillar Quanity | 4pcs |

| Weight (KG) | 9000 |

PLC control of temperature, pressure and process time

- The cylinder and plunger are made up of high –quality

materials.Simple and convenient structure , flexible operation,

commodious space.

- Memory accessible for process time,pressure and temperature.

- Rubust designed safety door(Automatic sensing interlock,

automatic pressure interlock)The control method can be changed as

client's requirements.

- Our hot plate is made of Q-235 steel , can resist high

temperature heating Without oil spilling or off pressure.Well done

insulation.

- Using best Advanced PLC control panel , vulcanization time be

setted in advanced.Mold speed can be adjusted according to

customers need.

Detailed Pictures

|