| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Metal Stamping Parts |

|---|---|

| Brand Name: | XCWY |

| Model Number: | MSP-017 |

| Place of Origin: | China |

| MOQ: | 500 pieces |

| Price: | $3.00/ Piece |

| Payment Terms: | T/T, MoneyGram, Western Union |

| Supply Ability: | 200000 Pieces per Month |

| Delivery Time: | 15-25 |

| Packaging Details: | Customize according to product situation |

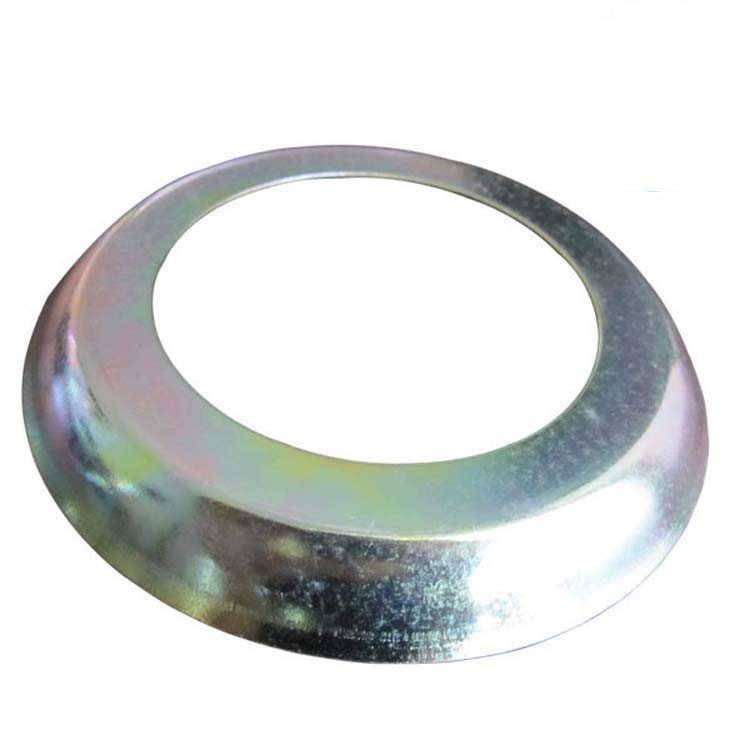

| Product Name: | Customized stamping parts |

| Color & Size: | Customized |

| Material: | steel |

| Surface Finish: | Sand blasting |

High Precision Cutting Machine Parts Steel Sheet Metal Stamping

Metal Stamping Parts

Xincheng Stamping manufacturers steels parts to meet the needs of your specific applications. Whether you need is a large, heavy part that requires thick walls for support, a small, intricate part, or a part that requires hardening and finishing after stamping, Xincheng Stamping has the capabilities to assist you.

We offer progressive stamping, and prototype stampings to ensure you receive the stamping product that best first your industry needs.

Operation

| Working Process | stamping, deep stamping, bending, punching, threading,welding, tapping, riveting |

| Material | Stainless steel, carbon steel,copper, brass, and bronze (according to customer's requirements) |

| Surface Finish | Anodize; polishing; zinc/nickel/chrome/gold plating, sand blasting, ect. |

| Tolerance | +/- 0.01--0.05mm / can also be customized |

| Certificate | ISO9001:2008 |

| Quality Control | Conducted by ISO/TS16949:2002 and ISO14001:2004 system. |

| Applications | auto,motorcycle,industry,ariculture,mine,furniture,elevator,etc |

| Thickness | 0.5mm~12mm, or other special available |

| File Format | Solidworks,Pro/Engineer,Auto CAD,PDF,JPG |

| Service | Warm and quick response service provided by the professional Export Sales Team with many years' experience in handling exports to the US, Europe, Japan and other countries and regions. |

| Inspection | IQC, IPQC,FQC,QA |

We can design automation equipment according to customer's product type, which can be applied to all processes of our production, including stamping, injection molding and assembly. Through self-designed and manufactured automation devices, we can achieve mass production while ensuring the stability and consistency of parts.

Our servies

|