50,000 tons of medium-sized organic fertilizer production line

The 50,000-ton organic fertilizer production line is a medium-sized

organic fertilizer production line with production capacity. At

present, the organic fertilizer production line is divided into

three levels of organic fertilizer production line complete sets of

equipment in accordance with the production capacity of large,

medium and small. At present, more than 75% of the small organic

fertilizer production lines on the market are less than 20,000

tons, or even ultra-small organic fertilizer production lines less

than 10,000 tons. Some family workshop-style small-scale organic

fertilizer production lines are poorly equipped or the production

line simplifies the process privately, resulting in insufficient

fermentation of the organic fertilizer during the fermentation

stage, or unreasonable selection of raw materials and ingredients,

resulting in substandard nutrients, or with local soil trace

elements. conflict. This is also the main reason why organic

fertilizer equipment manufacturers often recommend medium-sized

organic fertilizer production lines. The medium-sized organic

fertilizer production line refers to a production line with an

annual output of 30,000 to 70,000 tons.

50,000 tons of organic fertilizer production line equipment and

parameters

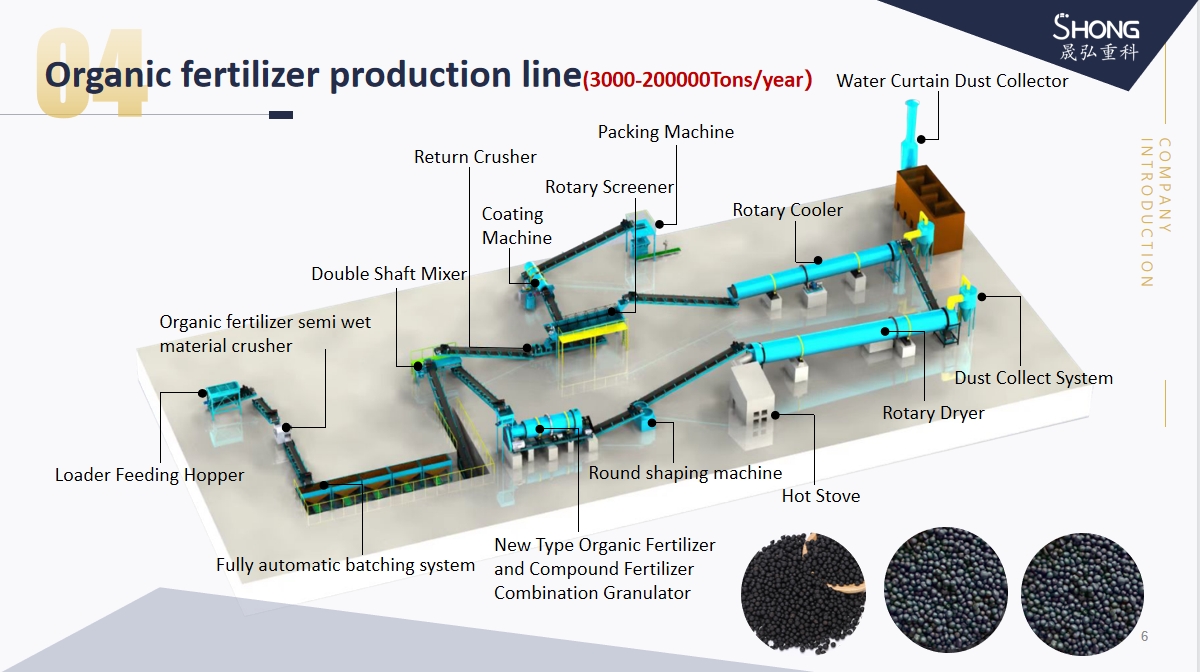

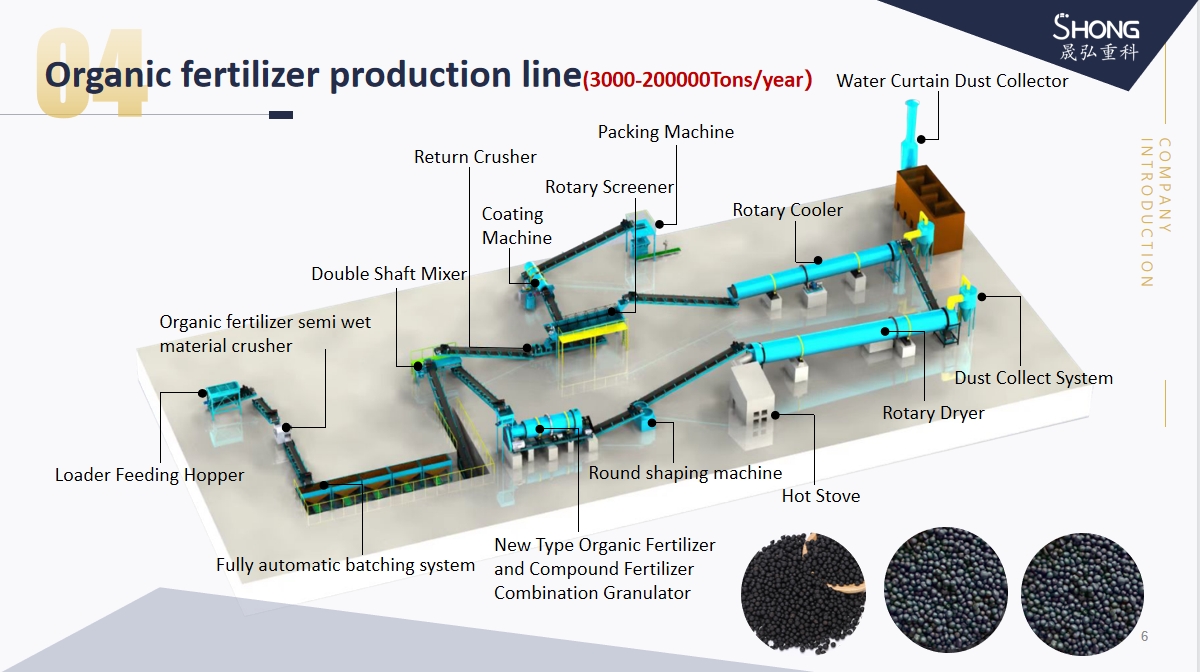

The main equipment of the 50,000-ton organic fertilizer production

line is the YSL2-120/200 type organic fertilizer combined

granulator. The process flow of this complete set of organic

fertilizer production line equipment is: fermentation → fully

fermented raw materials by turning over and throwing by the dumper

→ crushing by the pulverizer → Screening machine → automatic

batching system → double-shaft pulverizer crushing → granulation

machine granulation → dryer drying → dust collector dust removal →

cooler cooling → dust removal → cooling → coating machine coating →

screening machine screening → automatic packaging Machine packaging

→ finished product storage.

Advantages of 50,000 tons of organic fertilizer production line:

The 50,000-ton organic fertilizer production line has a high degree

of automation, mellow granulation, sufficient fermentation, and

high product qualification rate. It is the optimal plan for

investment in large and medium-sized organic fertilizer processing.

The structure of the new combination granulator for the production

line of 50,000 tons of organic fertilizer:

The YSL2 new type combined granulator on the medium-sized organic

fertilizer production line is composed of a body part, a

granulating rotor part and a transmission part. It is a

particularly important part of the complete set of equipment for

this series of organic fertilizer production lines. The working

principle of the new organic fertilizer granulator is that the

material enters the machine from the inlet at one end of the body,

and is continuously pushed by the granulating rotor and

mechanically moved with the casing to achieve the purpose of

granulation. The finished granules are at the other end of the

body. Push out of the machine. The rotor is driven by the motor and

reducer of the transmission part. The transmission part and the

body part are mostly fixed on the same frame. This is not only a

solid structure, stable operation, but also convenient

installation. It is a new era of environmentally friendly

fertilizer production equipment.

Main equipment and parameters of 50,000 tons of medium-sized

organic fertilizer production line equipment

| Remark | Equipment name | Specification model | Installed capacity (KW) | quantity |

| 1 | grinder | Packing Machine | 30 | 1 |

| 2 | Automatic batching machine | 1500 | 15 | 2 |

| 3 | Granulator | y3 type | 15x2 | 2 |

| 4 | Dryer | Φ1.8×18m | 15+22 | 1 |

| 5 | Cooler | Φ1.5×15m | 11+15 | 1 |

| 6 | Screening machine | 1.5 type | 7.5 | 2 |

| 7 | Packing Machine | 1 | 2.2 | 1 |