| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Insulating Glass Production Line |

|---|---|

| Brand Name: | Lijiang |

| Model Number: | LJXJ1000 |

| Certification: | CE |

| Place of Origin: | China |

| MOQ: | 1set |

| Price: | Negotiable, |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20set/month |

| Delivery Time: | 10days |

| Packaging Details: | wooden case or container |

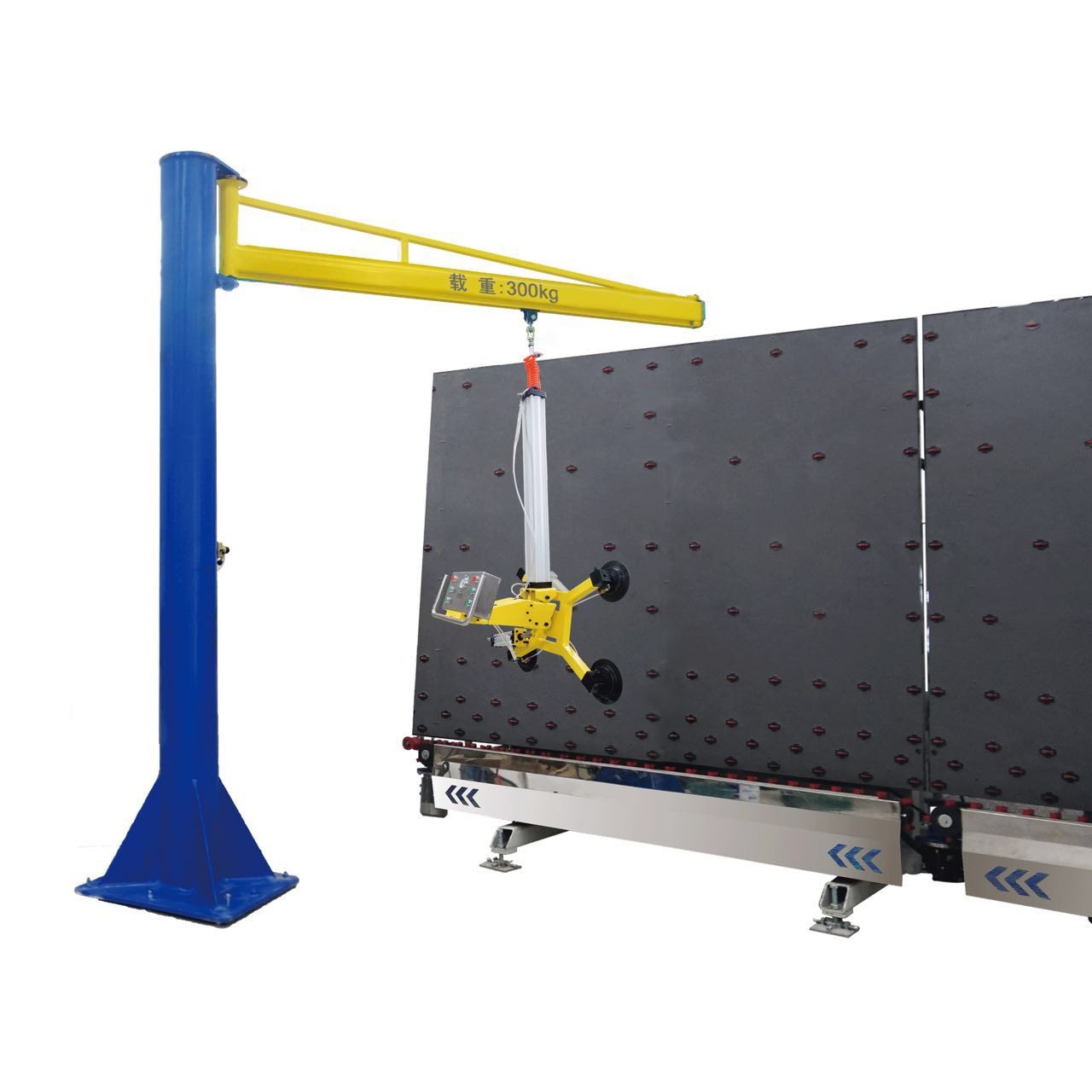

| Name: | Glass Cantilever Crane |

| Advantage: | with lifting sucker |

| Max lifting weight: | 1000KG |

| Suction cups: | 4 Pieces |

| Sliding method: | Manual |

| Air Control parts: | Airtac |

Lifting Cantilever Crane with four lifting suckers 1000KG for insulating Glass processing

Main Features of cantilever crane

It can select DC chaging vacuum pump,equipped with battery device.

-Maximum bearing capacity is 1000kgs (10 vacuum cups), Max. Glass

size can reach to 8m (The lifter with post can reach 3.9 meter)

-suitable for high-temperature glass

Glass Cantilever Crane with lifting sucker

1. This vacuum glass lifter is for handling insulating glass sheet.

2. This glass lifter is able to lift the glass sheet with 1000kg

3. It is equip with 5 suckers. But the sucker can be add according

to need of the client.

4. The equipment is Stable, Easy to use and safe.

5. The vacuum lifter is equipped with a warning light in case of a

power failure or vacuum leakage, an optical and an acoustic signal

goes off immediately to warn the operator to do emergency

operation.

Parameters:

| Max Glass weight | 800KG | |

| Rotation angle | Rotate 180 | Left and Right Up and Down |

| Suction cups | 4 Pieces | |

| Cup Materials | Silicone | |

| Sliding method | Manual | |

| Column height | 4 meters | Gas storage function |

| Arm length | 4 meters | |

| Air Control parts | Airtac |

Useing For

- Insulating Glass Production line,

- Installing Glass Curtain Wall System,

- Loading and Unloading glass sheet on glass cutting table,

- Instaling car windscreen.

Other products of LIJIANG GLASS

Automatic Aluminum Spacer Bending Machine LJZW2020

Main feature

• Adopt Siemens PLC control system, touch screen interface

• Japan FUJI CNC servo control system

• Four spacer size storage units

• Automatically cut and feed aluminum spacers

• Auxiliary function of adjustment for bending large aluminum frame

• Aluminum spacers are available in different sizes and sizes

• Bend shaped spacer frames continuously

• Separated guard board outside of bender

• Automatically avoid the connection while bending and cutting

• Pause and Reset device for handling equipment failures

• USB input function, read the excel format file directly etc (Optional)

• Spacer printing code function (Optional)

• Printing label sticker function (Optional)

• Can bend aluminum spacer and stainless steel ( Optional)

• Automatic drill gas filling hole (Optional)

• Connect to ERP system (Optional)

Technical data

| Max. bending size | 2000mm*2000mm (2500*2500mm) |

| Min. bending size | 250mm*200mm |

| Aluminum spacer width | 5.5-27mm |

| Dimensional error | ±0.5mm |

| Angle error | ±1º |

| Processing speed | ≤26s |

| Air supply | ≥0.65MPa |

| Total power | AC220/380V 50Hz 2.5KW |

| Dimension | 10500mm*2200mm*2600mm |

Electrical parameters

| NAME | BRAND | NAME | BRAND |

| PLC | GERMAN SIEMENS | Triplet | Taiwan AIRTAC |

| Low voltage electrical apparatus | GERMAN SIEMENS | Cylinder | Taiwan AIRTAC |

| Servo motor | JAPAN FUJI | Solenoid valve | Taiwan AIRTAC |

| Servo driver | JAPAN FUJI | Switch power | Taiwan TEND |

| Relay | JAPAN OMRON | TOUCH SCREEN | Taiwan WEINVIEW |

| Sensor | KOREA AUTONICS | GUIDE | Taiwan TBI |

LJWBQJ-2500A Glass Washing Machine

glass washing machine CP-2500A used for cleaning and drying the upper and lower surfaces of ordinary plate glass and high quality low-e glass,it is composed of incoming segment, cleaning air-drying segment and outgoing segment.

high efficiency, energy saving 70% efficiency;

2. The rest of the sheet metal parts are sprayed with advanced mechanical

paint or powder;

3. The rubber roller is made of vulcanized rubber with stainless steel shaft;

4. The washing part in contact with water is made of stainless steel;

5. Cleaning department, wind staff overall lift, the maximum lift: 350mm,easy to clean and maintain;

6. Three pairs of brush(Ø150mm)Stainless steel shaft configuration (low-e glass, ordinary coated glass and sunshine coated glass can be washed without damaging the coated surface);

7. Two pairs of special stainless steel aluminum alloy air knife configuration, strong wind, good air drying effect, with heating system(with temperature control device, optional opening and closing);

8. The fan is equipped with air filter in the air inlet chamber, with large air volume and good air drying effect,The whole fan box is installed in the upper part of the workshop, with the air filter screen on the side for easy inspection and cleaning;

9. Main drive for gear transmission, frequency control, digital display , the rotation of the brush roller in the washing section is driven by independent belts of the upper and lower motors respectively, the frequency conversion adjustment speed is stable, the service life is long, realizes the cleaning high request special glass;

10. Mechanical button control, cleaning machine digital display, easy to operate, easy to operate, easy to maintain;

11. Washing machine water tank outside, convenient water tank cleaning, water change, check, so that the washing machine cleaning effect is cleaner.

12. Optional with PLC control, touch screen display.It is convenient for workers to operate and maintain, and can be connected to all manufacturers of edge grinding machines without gap.(purchase separately if necessary)

1. Maximum glass width: 2500mm (effective maximum: 2650mm)

2. Minimum glass specification: 400mm×400mm (limited to single row on left and right sides)

3. Glass thickness: 3mm-25mm (digital display)

4. Speed range: glass thickness within 3-25mm Vmax=1-12m/min

5. Main drive, brush speed regulation method: frequency control

6. Table height :900±25mm

| Maximum glass width | 2500mm (effective maximum: 2650mm) |

| Minimum glass specification | 400mm×400mm (limited to single row on left and right sides) |

| Glass thickness | 3mm-25mm (digital display) |

| Speed range | glass thickness within 3-25mm Vmax=1-12m/min |

| Main drive, brush speed regulation method | frequency control |

| Table height | 900±25mm |

| Total power | 42KW(water-bearing wind heating: 15KW) |

| Water source | self-circulation, tap water (according to civil water standards) and deionized water water supplement (deionized water equipment shall be provided by the buyer) |

| Power source | 380V 50Hz |

| Dimensions (length × width × height) | approximately 6260*4800*3100 |

| Weight | 3940kg |

|