| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Magnesium Alloy Die Casting |

|---|---|

| Brand Name: | DOME |

| Model Number: | DM006 |

| Certification: | ISO9001,CE,SGS |

| Place of Origin: | Zhengzhou,China |

| MOQ: | 10Pcs |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Delivery Time: | 15-30 work days |

| Packaging Details: | wooden case |

| Material: | Magnesium Alloy |

| Size: | As Requirements |

| Color: | As Requirements |

| Dimensions: | Customized Sizes |

| Process: | Casting, Die Casting. Deburring .CNC Machining .Checking.Packaging |

| Product name: | die casting |

| Service: | Drawing Custom |

| Lead time: | 20days |

| Application: | Machinery Parts |

| Standard: | ASTM |

| Company Info. |

| Dome Metals Co., Ltd. |

| View Contact Details |

| Product List |

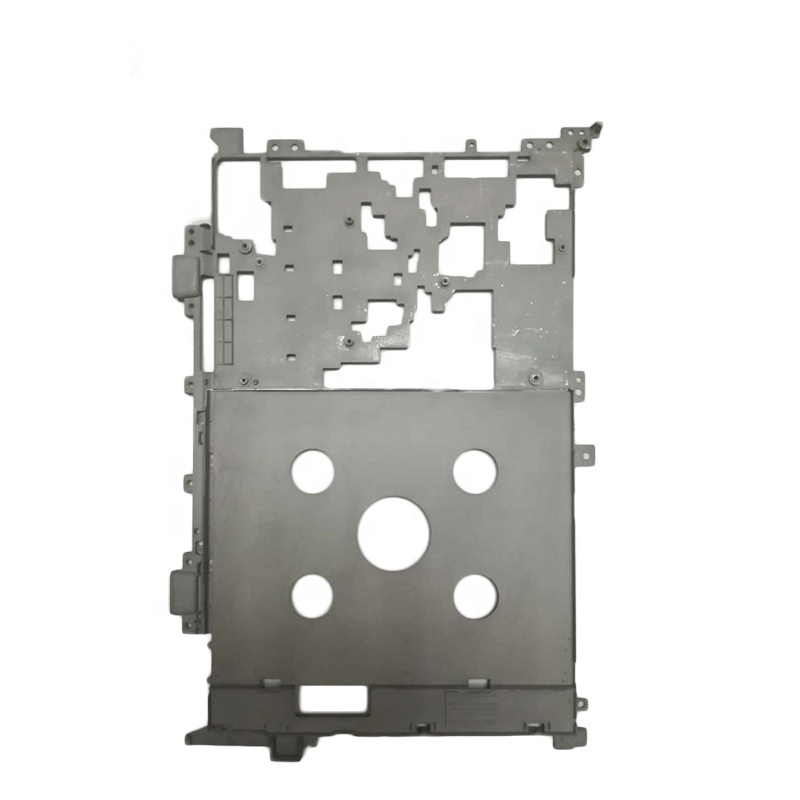

Magnesium Alloy Die Casting Laptop Frame Spare Parts Alloy AZ91D, AM60B

Magnesium alloy

As the lightest structural material, magnesium alloy has low

specific gravity (about 23% of steel and 64% of aluminum) and

high specific strength and stiffness.Good thermal and electrical

conductivity;With good electromagnetic shielding, damping,

shock absorption, and cutting and die casting process performance.

Weight: magnesium alloy is 36% lighter than aluminum alloy, 73%

lighter than zinc, and 77% lighter than steel.

Specific strength: magnesium alloy is equivalent to aluminum alloy

and steel, much higher than fiber reinforced plastics;

Wear resistance: the wear resistance of magnesium alloy is much

higher than that of die-cast aluminum alloy A380;

Damping performance: magnesium alloy is 30 times higher than

aluminum alloy;

Others: magnesium alloy is 200 times higher than plastic in thermal

conductivity, thermal expansion performance is only

half of the plastic.

| Product Name | Magnesium Die Casting |

| Material | Magnesium alloy AZ91D, AM60B |

| Processing Craft | Drawing, Mold, Die casting, Deburring, Drilling holes, Tapping, CNC machining, Polishing, Surface treatment, Assembly, Quality inspection, Packing, Delivery |

| Tolerance | ± 0.02mm |

| Surface Treatment | Chrome Plating,Zinc Plating,Nickel plating,Electrophoresis,Anodization,Polishing,Powder coating,Sandblasting,Passivation,Spray painting, Etc |

| Quality Assurance | ISO9001:2015 Certified,SGS Certification |

| Quality Guarantee | Two years |

| Inspection | 1. Foundry in-house: 100% inspection on critical dimension; 100% on appearance. 2.Third Party inspection available upon requirement |

| Mainly Testing Facility | Three dimensional measuring instrument, Salt spray test box, Dynamic balance detector, Pneumatic detection |

| Payment term | T/T |

| Lead time | Usually 20 days after order confirmed |

| Delivery | Sea transportation, FedEx, DHL UPS for Urgent Delivery |

Features & Advantage | 1. High machining accuracy,The flatness within 0.05mm. 2. High strength and not easy to deform, has good electrical and thermal conductivity. 3. High finish appearance,Smooth surface roughness is 3.2 after machining. 4. The machining precision is high and the assembly structure is seamless. |

| Standard | 1.Aluminum alloy : ISO3522-84, ASTMB85-96, ASTMB597-98,JISH2118:2000,

JISH5302:2000 2.Magnesium alloy : ISO/DIS16220-1999, ASTMB93/B93M-98,JISH2222-1991, JISH5303-1991, EN1754-1997 3.Zinc alloy: ISO301-1981, ASTMB86-98, ASTMB240-98, ASTMB327-98, JISH5301-90, JISH2021:1999, EN 1774-1997, EN12844:1998, AS1881-1986 |

| Application | Auto parts and accessories, Pump & valve parts and accessories, Food machinery parts,Mechanical Components, Industrial locks, Hardware tools, High-speed rail accessories, Construction hardware, Boat parts and Marine hardware, Petroleum machinery, Heat-treatment equipment, Agricultural machinery, Furniture part, Led lighting parts, Other industry metal casting parts |

|