12 Core Anti-Termite Outdoor Fiber Optic Cable Non-Metallic

Strength Member Layer Filling Loose Tube PE Sheath GYFTY04

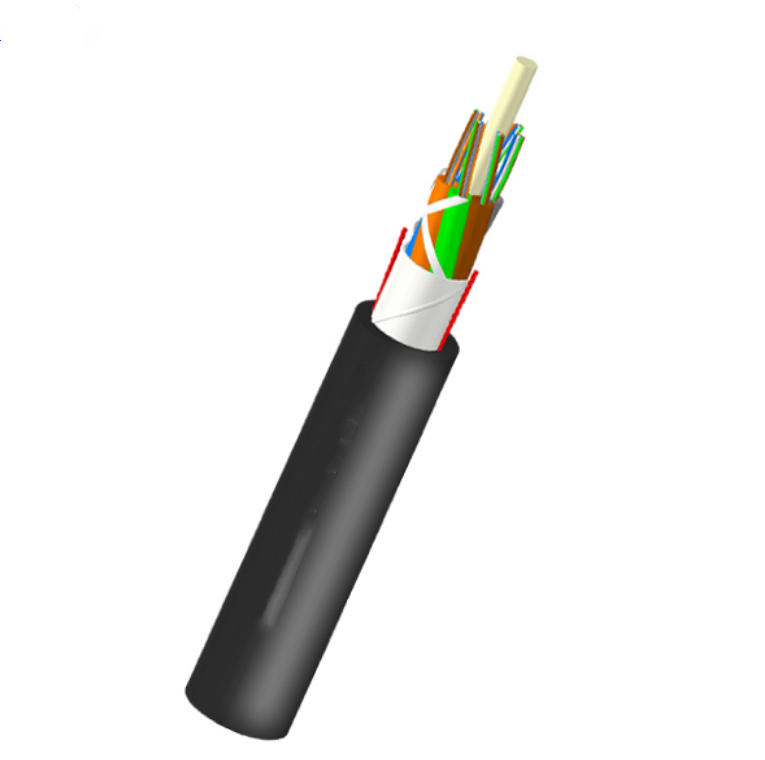

Description:

The fibers, 250µm, are positioned in a loose tube made of a high

modulus plastic. The tubes are filled with a water-resistant

filling compound. A Fiber Reinforced Plastic (FRP) locates in the

center of core as a non-metallic strength member. After the cable

core is filled with the filling compound to protect it from water

ingress, the cable is completed with a PE sheath.

Features:

1. low transmission attenuation and dispersion.

2. Reasonable design, precise control of excess length of fibers in

the loose tube and optimum cabling process provides the cable

excellent mechanical and environmental properties.

3. The SZ-stranded, loose tube design isolated fibers from

installation and environmental rigors.

Application:

Backbones and Access.

Installed in ducts, lashed/Aerial.

| Model | Description | Applications |

|

| GYFTY04 | GYFTY04 outdoor fiber optic cable,Non-metallic strength

member,layer filling loose tube,PE sheath,Anti-termite | Overhead&Pipeline laying&Strong electromagnetic and high

voltage Area,Anti-termite |

| Tensile Strength (N) | Crush Resistance (N/100mm) | Bned Radius

(mm) | Working Temperature(℃) | Max. attenuation (dB/km) |

| Long term | short term | Long term | short term | Static(D) | Dynamic (D) | Min.TA | Max.TB | 1310μm | 1550μm |

| 600 | 1500 | 300 | 1000 | 10 D | 20 D | -40℃ | +60℃ | ≤0.36 | ≤0.22 |

| Category | Description | Specifications |

| G.652D |

| Optical Specifications | Attenuation | @1310nm | ≤0.36dB/km |

| @1550nm | ≤0.22dB/km |

| Attenuation discontinuity | ≤0.05 dB |

| Attenuation vs. Wavelength | @1285~1330nm | ≤0.05 dB/km |

| @1525~1575nm | ≤0.05 dB/km |

| Zero Dispersion Wavelength | 1300~1324nm |

| Zero Dispersion Slope | ≤0.092ps/(nm2.km) |

| Dispersion | @1310nm | ≤3.5 ps/nm.km |

| @1550nm | ≤18 ps/nm.km |

| Polarization Mode Dispersion(PMD) | ≤0.2ps/km1/2 |

| Cable Cutoff Wavelength(λcc) | ≤1260nm |

| Effective Group Index of Refraction | @1310nm | 1.4675 |

| @1550nm | 1.4681 |

| Macro bend loss (30mm radius,100turns) 1625nm | ≤0.1 dB |

Geometric

Specifications | Mode Field Diameter | @1310nm | 9.2±0.6μm |

| @1550nm | 10.4±0.8μm |

| Cladding Diameter | 125±1μm |

| Cladding Non-Circularity | ≤1.0% |

| Coating Diameter | 245±7μm |

| Coating/Cladding Concentricity Error | ≤8μm |

| Core/Cladding Concentricity Error | ≤0.8μm |

Mechanical

Specifications | Proof Test level | ≥1.0% |

| Fiber Curl Radius | ≥4.0m |

| Peak Coating Strip Force | 1.3~8.9N |

FAQ

1. Are you the real manufacturer?

Yes. We are the real manufacturer with 18 years' history.

2. What is your fiber brand ?

Corning, SEI, YOFC, FiberHome, etc

3. Can you accept small order?

Yes, small order is available .We support new project of our

customers as we know business is always from small order.

4.What is your warranty period?

25 years for fiber optic cable

5. Which kind of certification you have ?

ISO9001, SGS, 3C Anatel.

6. What is your delivery time?

Usually within 2-3 working days

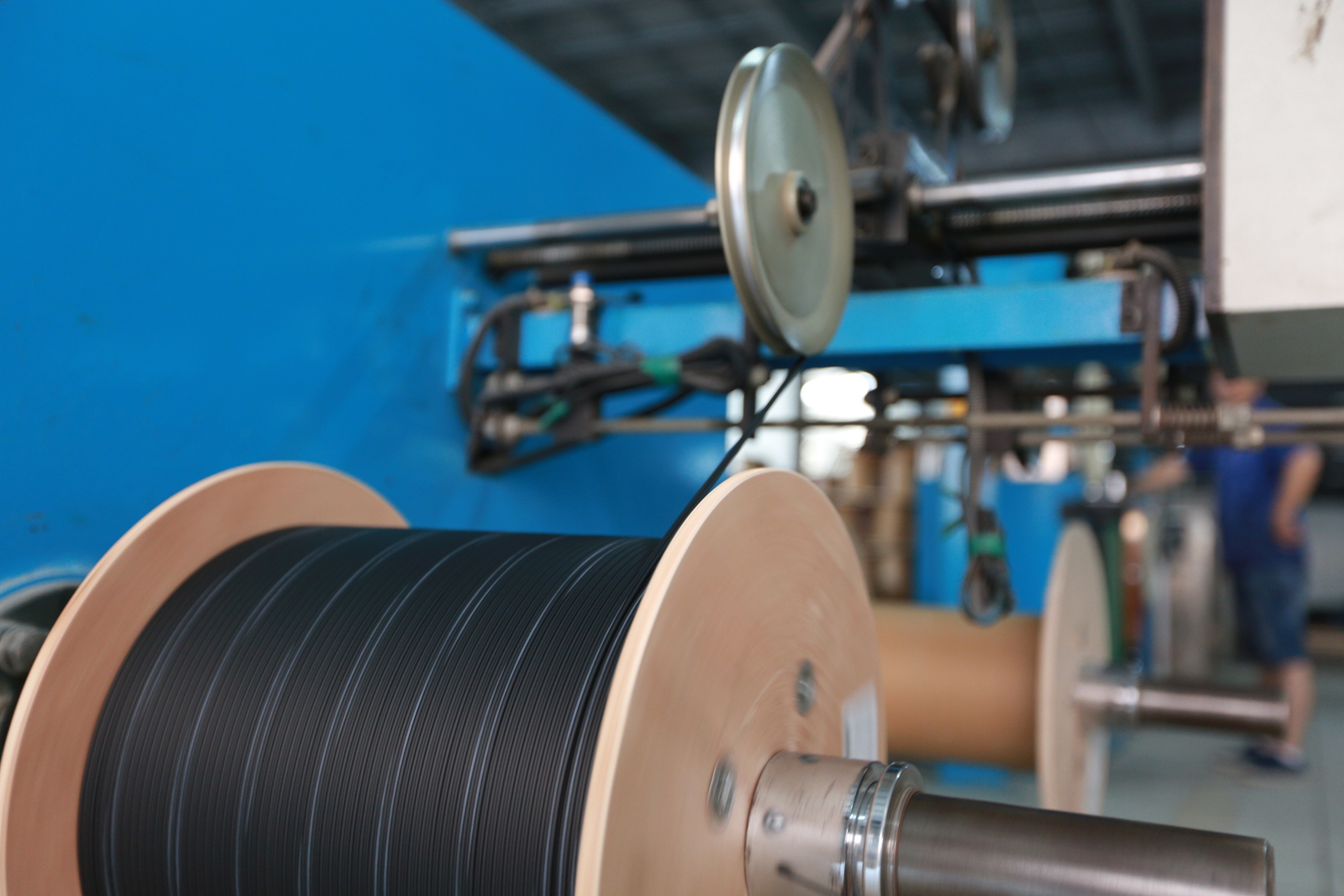

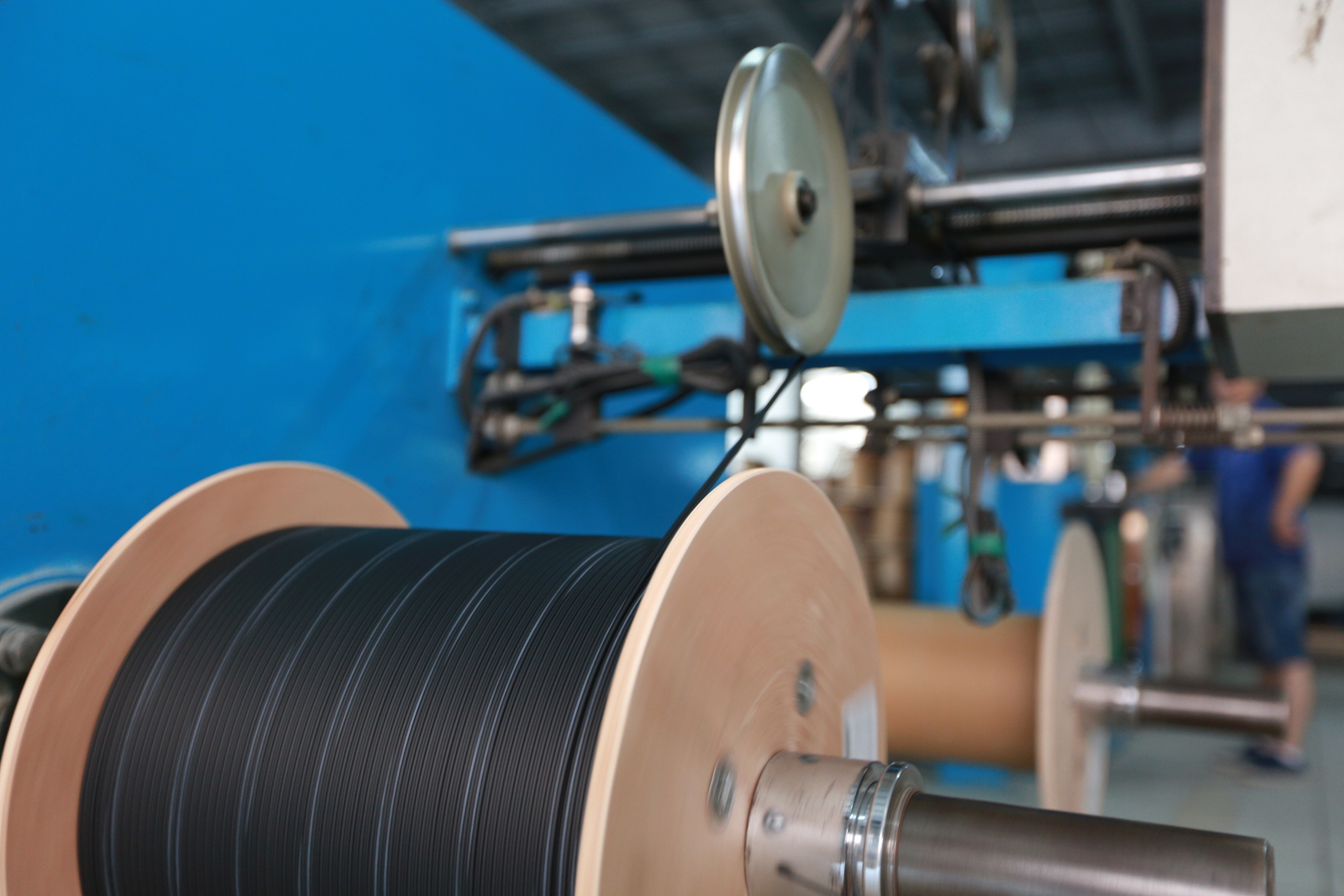

7. What about your annual production capacity?

Outdoor/Indoor Fiber Optic Cable, our annual output is 8,000,000

KM;

FTTH/FTTX/FTTA Cable, it is 6,000,000 KM per year;

Patch Cord/Pigtails, it is 12,400,000 Pieces per year.

8. What is your payment way?

T/T, L/C, Western Union and Paypal.

9. Can you supply customized products and logo?

-Yes. We supply OEM&ODM service. You can send us your drawing.

10. Can you supply your cable test value form?

-Yes. After finishing production , we can supply if you ask.

11. Do your factory inspect every roll of cables?

-Yes. we factory do 100% inspection per order.