| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | PET Recycling Line |

|---|---|

| Brand Name: | BEAKELAND |

| Model Number: | 500KG/H |

| Certification: | CE |

| Place of Origin: | JIANGSU,CHINA |

| MOQ: | 1 SET |

| Price: | Negotiation |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 10 SET/ YEAR |

| Delivery Time: | 65 WORKING DAYS |

| Packaging Details: | Standard Export Package |

| Name: | PET bottle recycling line |

| Application: | PET bottle recycle |

| Production capacity: | 500kg / h |

| Voltage: | 380V,50HZ,3P(customized) |

| Products Moisture: | 1 - 2% |

| Main Processing: | Sorting Crushing Washing Drying |

| Impurity: | 100 - 300 ppm |

| Final particle size: | 8-16mm |

CE Cerfified Waste PET Bottle Recycling Line

Despriction:

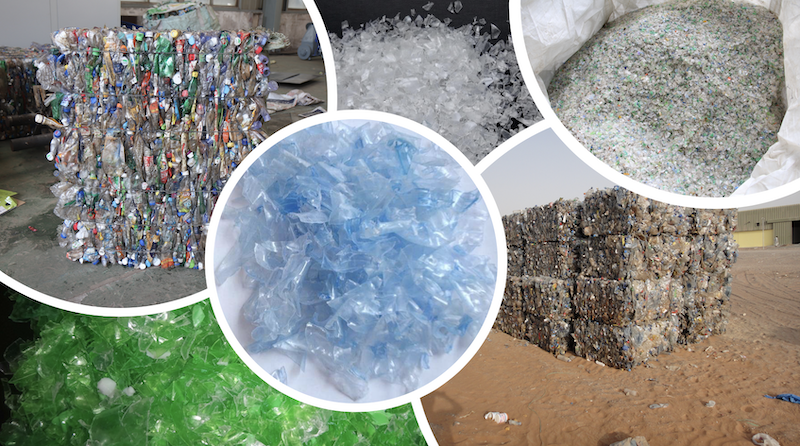

The waste PET bottle crushing washing recycling machine line is used for crushing, cleaning, separation of bottle cap and label, depriving of impurity and glue material, and drying for bottle flakes. Then those waste PET bottle will become reusing PET materials.

We have several different standards of PET bottle crushing washing recycling machine line according to different production capacity and requirement for cleaning (capacity of 300-3000kg/h).

Customers can have PET bottle crushing washing recycling machine line to produce high quality PET flakes for selling, drawing filament, producing PET particles or blowing bottles.

Models&specifications:

| Model | BKL-500 | BKL-1000 | BKL-1500 | BKL-2000 | BKL-3000 |

| Capacity(kg/h) | 500 | 1000 | 1500 | 2000 | 3000 |

| Installation Power (kw) | 150 | 250 | 300 | 400 | 500 |

| Labor | 2-4 person | 3-5 person | 5-6 person | 6-8 person | 8-12 person |

Components of a typical PET bottle recycling line:

| Belt conveyor | For waste material infeeding |

| Bale Breaker | opens the tight bales of PET bottles |

| Trommel screen | separate heavy stones, caps, sand or other small contamination down |

| Pre-washing machine | Pre -Washing the whole bottle surface |

| Label remover | Remove 95% lables on bottles before crushing |

| Sorting belt | sorting the dirties out before granulating. |

| Metal Detector | detects metal contamination |

| Granulator / Crusher | Wet crushing bottles to flakes size |

| Screw conveyor | Conveying material to downstream machines |

| High speed Friction washer | Scrub washing and cleaning flakes |

| Single screw or double screw washing tank | flakes floating washing and conveying. |

| Hot Washing Tank/ steam washer | Hot wash with detergent for clean flakes and remove glue |

| Horizontal dewatering machine ( Dehydrator ) | Dehydrate flakes to dry flakes |

| Second granulator (optional) | Crush flakes to final size required. |

| Zig-Zag label separato (air classifier) | separate labels in the crushed flakes. |

| Wind conveying system | Material transport and bagging |

| Control cabinet | control the whole system intensively. |

Final PET products quality for reference:

Machine line Features:

Detailed Photos:

Debaler

Sorting conveyor

Crusher

|