Wuxi ShiLong Steel Co.,Ltd.

About Us

Wuxi ShiLong Co., Ltd has been engaged in steel industry for more

than 11 years. It is located in Jiangsu, Wuxi province, China.Only

15 minutes away from Wuxi High Speed Railway Station.With high

quality standard, meticulous workmanship, strict quality

control,professional service, ShiLong aims to provide our

customers, distributors and suppliers with win-win cooperation.

Our Products

We are famous in our country with good reputation, high-quality

products, solid strength and lower price. Our products include cold

rolled/hot rolled stainless steel plate, stainless steel coil,

stainless steel plate for many domestic and foreign steel

enterprises including Shanxi Tisco.Zhangjiagang Pohang Iron & Steel

Co., LTD.(ZPSS), Shanghai Baosteel Co., LTD., Ningbo Baoxin Iron &

Steel Co., LTD., Taiwan region, Mainland China and many foreign

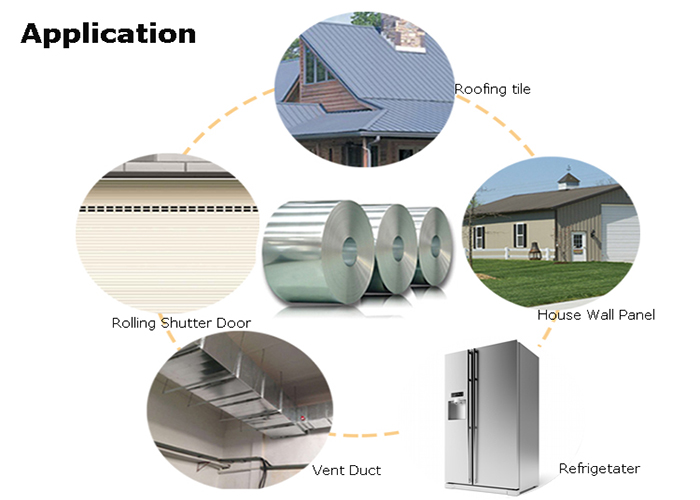

countries and regions. These products are applied to engineering,

coal mine, textile, electric power, boiler, machinery, military

industry and other fields.

We also keep the business relationship with several Chinese

state-controlled enterprise(China Railway 11 Bureau Group Co., Ltd.

and China Railway 10 Bureau Construction Co., Ltd., etc.) and we

have taken part in the Beijing-Shanghai high-speed railway national

construction project (Jinan part), Zhangjiakou Hohhot high speed

railway national construction projects in China, supplying steel

associated materials to the construction project.

Certificate Of Quality

Warehouse

We have enough steel sheets in stock, can start cutting

instantly,which can make us ship the delivery within 7-15

days(depends on the certain situation).

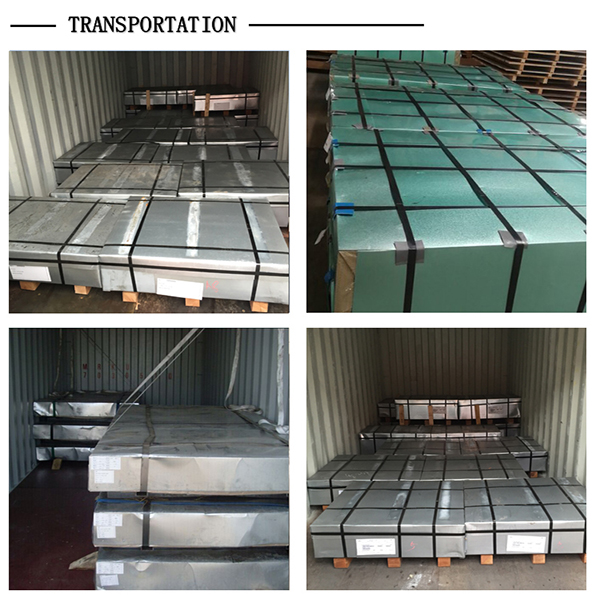

Packages

Sales&Service

Our products have been exported overseas including Southeast Asia,

Europe, North America, South America. Apart from overseas market,

we also operate a large number of domestic trade which includes

supplying steel material for several Chinese national

infrastructure construction projects.

Our service

Pre-sale service ;Free sample. If customer have the require of the

sample, we can provide sample for free.

Sales service ;Special process. We can provide other process

service. Like : cutting, bending,polished, coloured, galvanized.

After-sales service :We make sure the good quality of our products.

Any problems of the quality we will deal immediately, loss because

of the quality , we will compensation for customer.

If you are interested in any of our products or would like to

discuss a custom order, please feel free to contact us. We are

looking forward to forming successful business relationships with

new clients around the world in the near future.