| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Superheater Coil |

|---|---|

| Brand Name: | HD BOILER |

| Model Number: | Rear Wall Evaporator |

| Certification: | ISO9001 , SGS , TUV , ASME , EN |

| Place of Origin: | Zhangjiagang,China |

| MOQ: | 5 tons |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 800 Tons / Month |

| Delivery Time: | 60 Days |

| Packaging Details: | Steel Frame |

| Material of Tube: | SA106 Gr. B and SA192M |

| Product Name: | Rear Wall & Evaporator |

| Standard: | ASME |

| Application: | Sugar Mill and Power Plant Boilers |

| Keyword: | Evaporator Coils and Serpentine Coils |

| Material of Fin: | Q235B |

| Company Info. |

| Zhangjiagang HuaDong Boiler Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

High Temperature Evaporator Serpentine Coils Assembly ASME Standard

Introduction

For over 30 years, Hua Dong Boiler has been consistently innovating and improving our boiler spare parts. The improvements in bending, welding and design ensure our products meet both European and American standards, ensuring a reliable performance.

Serpentine tube is a tube that twists and turns several times in a plane.The convection heating surface of the boiler, such as economizer, superheater and reheater, adopts the structure of serpentine tube through the belt, with horizontal and vertical layout.

Evaporative tube bundle is an evaporative tube bundle mainly absorbing convection heat transfer in small and medium capacity boiler. It is generally a bundle of dense staggered tube system composed of ascending and descending tubes connected with upper and lower drum.Evaporation tube bundle pipe heat load is high, this part of the pipe by hot water into steam, from the bottom up;Its main function is to absorb heat to the water and steam and to serve as the rising part of the boiler water cycle.

1. Material composition: It is made up of snake-like tubes (carbon

steel, alloy steel or heat-resistant steel, etc.) and collection

boxes and other supporting material. Tubes generally have 32, 38,

42 or other types of specifications, according to user's needs

separately.

2. Arrangement: vertical or horizontal layout.

3. Features: beautiful appearance, size, accuracy, first-class

bending and welding technology, first-class detection equipment.

Superheater

Fossil fuel power plants often have a superheater section in the

steam generating furnace.The steam passes through drying equipment

inside the steam drum on to the superheater, a set of tubes in the

furnace. Here the steam picks up more energy from hot flue gases

outside the tubing, and its temperature is now superheated above

the saturation temperature.

Reheater

Power plant furnaces may have a reheater section containing tubes

heated by hot flue gases outside the tubes. Exhaust steam from the

high-pressure turbine is passed through these heated tubes to

collect more energy before driving the intermediate and then

low-pressure turbines.

Type | Advantages | Disadvantages | Supporting method |

Pendant-type | 1.Firm structural support | 1. Flow blockage by condensed steam 2. Needs slow restart to purge

the water that accumulates in the bottom. | supported from above |

Inverted-type | 1.Proper drainage of the condensed steam | 1. Lack the structural rigidity, especially in high speed gas flow | Supported from below |

Horizontal -type | 1. Proper drainage 2. Good structural rigidity | 1. They do not view the flam directly so they are mainly from the

convective type | Usually supported in the vertical gas ducts parallel to the main

furnace. |

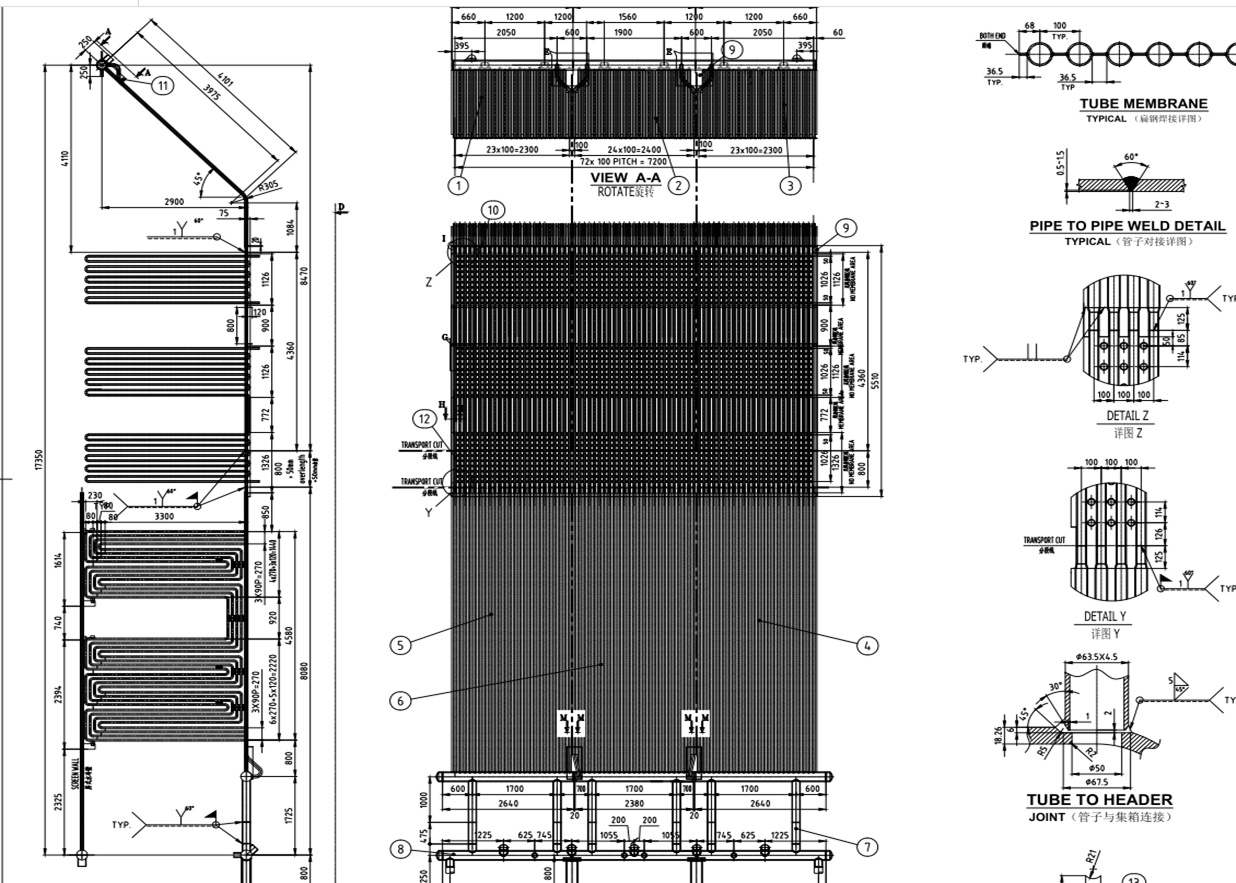

The drawing here is the evaporator assembly with membrane wall and evaporator coils for your reference.

This project also include steam drum+header+economizer.

| DESIGN AND FABRICATION CODE | ASME SECTION I, 2019 EDITION |

| DESIGN PRESSURE | 8.1 MPa |

| MAX. ALLOWABLE WORKING PRESSURE | 8.1 MPa |

| DESIGN TEMPERATURE | 320℃ |

| HYDROSTATIC TEST PRESSURE | 12.2 MPa |

| CORROSION ALLOWANCE | 0.5mm |

|