| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Single Side Spot Welding Machine |

|---|---|

| Brand Name: | XWH |

| Model Number: | DND3 |

| Certification: | CE |

| Place of Origin: | China |

| MOQ: | 1 |

| Price: | USD4000-USD5000 |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram |

| Supply Ability: | 500 sets/month |

| Delivery Time: | 15 working days |

| Packaging Details: | Wooden Case |

| Product name: | Manual Auto Body Single Side Spot Welding Machine |

| Application: | Automotive Industry |

| Machine type: | Resiatance Welding Machine |

| Welding material: | Alloy Metal Aluminum Stainless Steel |

| Voltage: | 220V/380V/415V/440V |

| Max. Welding Thickness: | 1.5+1.5mm |

| Feature: | Portable |

| Rated Duty Cycle: | 50% |

| After Warranty Service: | Video technical support, Online support and Spare parts |

| After-sales Service Provided: | Free spare parts, Field installation, commissioning and training |

| Company Info. |

| Chengdu Xingweihan Welding Equipment Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Product Introduction:

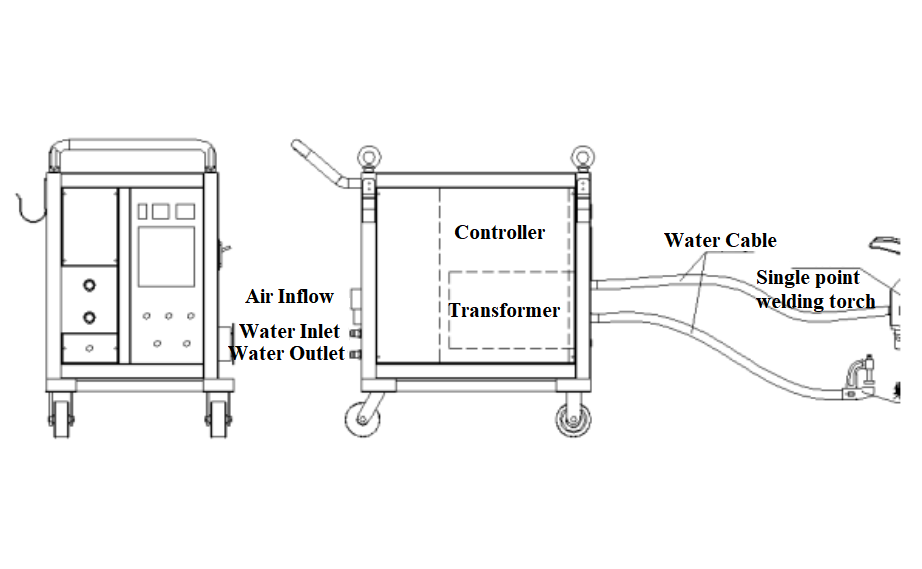

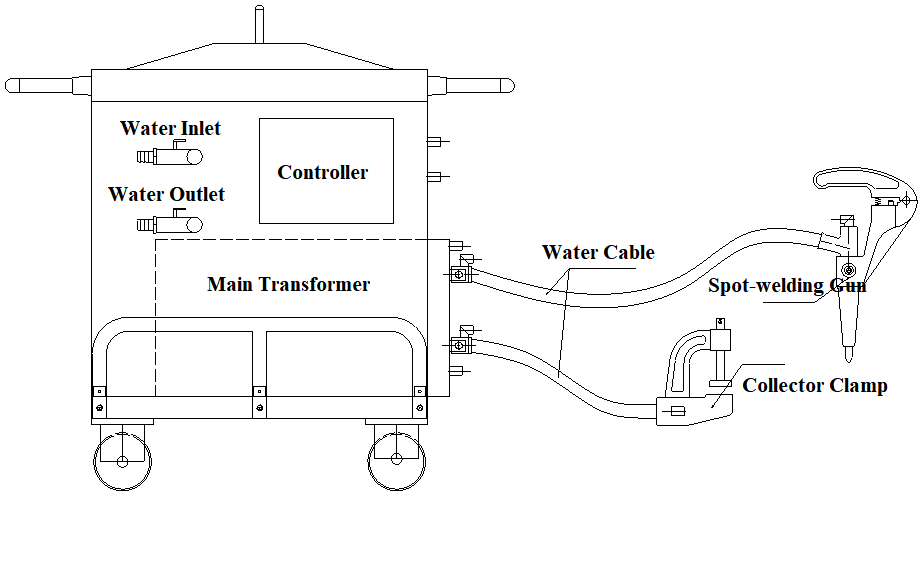

Suspension Spot Welding Machine is a resistance welding equipment designed to separate the welding transformer from the welding gun. It is connected by a high-voltage cable to achieve physical separation of energy transmission and welding operation. Its modular structure is suitable for high-frequency and high-intensity continuous welding operations, especially for industries such as automobile manufacturing and home appliance production.

Technical Parameters:

Model Item | DND3-125 | DND3-160 | DND3-200 |

| Fixed capacity (KVA) | 125 | 160 | 200 |

| Secondary unload voltage (V) | 21 | 22.3 | 24.5 |

| Rated duty cycle (%) | 50 | 50 | 50 |

| Max. short circuit current (KA) | 12 | 14 | 18 |

| Max. thickness of mild steel sheet(mm) | 1.0+Framework | 1.5+ Framework | 2.0+Framework |

| Weight (Kg) | 145 | 210 | 280 |

Features:

1.Modular design:

The transformer and welding gun are installed independently, which

is easy to maintain and has better heat dissipation performance.

Can be paired with various welding guns (X-type, C-type, servo

pressure type) to meet different welding needs.

2.Lightweight operation:

The weight of the welding gun is only 1.5-3kg (integrated welding

guns usually weigh over 5kg), reducing operational fatigue.

Suitable for long-term continuous welding to improve production

efficiency.

3.High power output:

Adopting a dual-mode cooling system of water and air, it can

sustain high current welding (for models above 100kVA).

Suitable for high conductivity materials such as aluminum alloys

and galvanized steel sheets.

General Structure:

FAQ:

|