| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Custom Metal Stamping Parts |

|---|---|

| Brand Name: | DX |

| Certification: | IATF16949 |

| Place of Origin: | China |

| MOQ: | 1000pcs |

| Price: | Negotiable |

| Payment Terms: | T/T |

| Supply Ability: | 30000pcs per month |

| Delivery Time: | 25days |

| Packaging Details: | Bag,box/carton, pallet /crate |

| Product: | Custom metal stamping part |

| Material: | Q234,08F,Q345,Q295,D12,D41 |

| Surface: | Plating,Polishing, sand blasting, etc |

| Applied Software: | PDF/STEP/SolidWorks/DWG/DFX/CAD/IGS,etc. |

| Certificate: | ISO9001, IATF16949 |

| Manufacturing process: | Laser cutting , punching,stamping,surface finish |

| Service: | Customized OEM ODM |

| Application: | Appliance, Auto, Building, Capital equipment, Energy, Instrumentation, Medical device, Telecommunications |

| Company Info. |

| Jiaxing Dexun Co.,Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

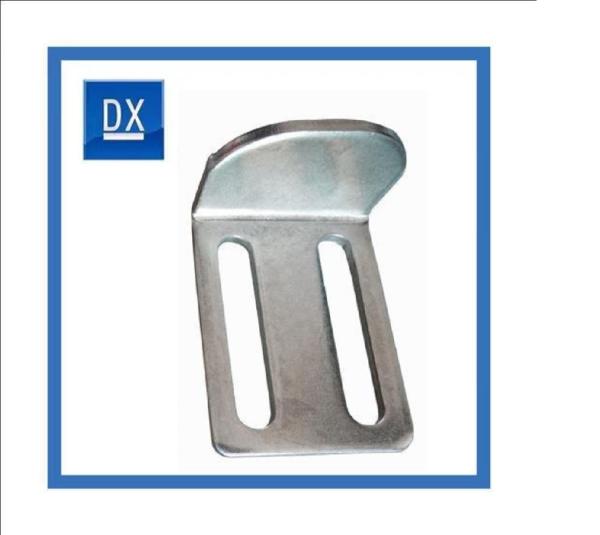

Custom metal stamping part

Stamping parts limit deviation: hole size press the deviation is 0, the upper deviation is the lower deviation plus dimensional tolerance; Shaft dimensions specify the upper deviation as the basic deviation, with a value of 0, and the lower deviation as the upper deviation minus the dimensional tolerance. For the distance between the center of the hole, the distance between the edge of the hole, the length of bending, drawing, height and so on, the upper and lower deviation is stipulated to be half of the dimensional tolerance.

| Description | Custom metal stamping part |

| Testing tool | 3D projectors, ordinary projectors, all kinds of accurate measuring tools, Salt spraying testers, high temperature resistant testers, low temperature resistant testers, etc... |

| Finish | Passivation, heat treatment, power coating,etc. |

| Material | Q234,08F,Q345,Q295,D12,D41,etc. |

| Quality system | RoHS ,ISO, IATF |

| Tolerance | +/-0.1 mm |

| Service type | OEM/ODM |

| Application | furniture, mechanical equipment, daily living equipment, electronic sports equipment etc. |

Inspection method:

1) Touch inspection

2) Abrasive polishing

3) Unction inspection

4) visual inspection

5) Gage inspection

|