| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | PTFE Filter Bags |

|---|---|

| Model Number: | customized |

| Place of Origin: | China |

| MOQ: | negotiable |

| Price: | negotiable |

| Supply Ability: | TBD |

| Delivery Time: | TBD |

| Packaging Details: | polybag and pallets for bags and steel crates for cages |

| Brand Name: | 17s |

| Certification: | ISO |

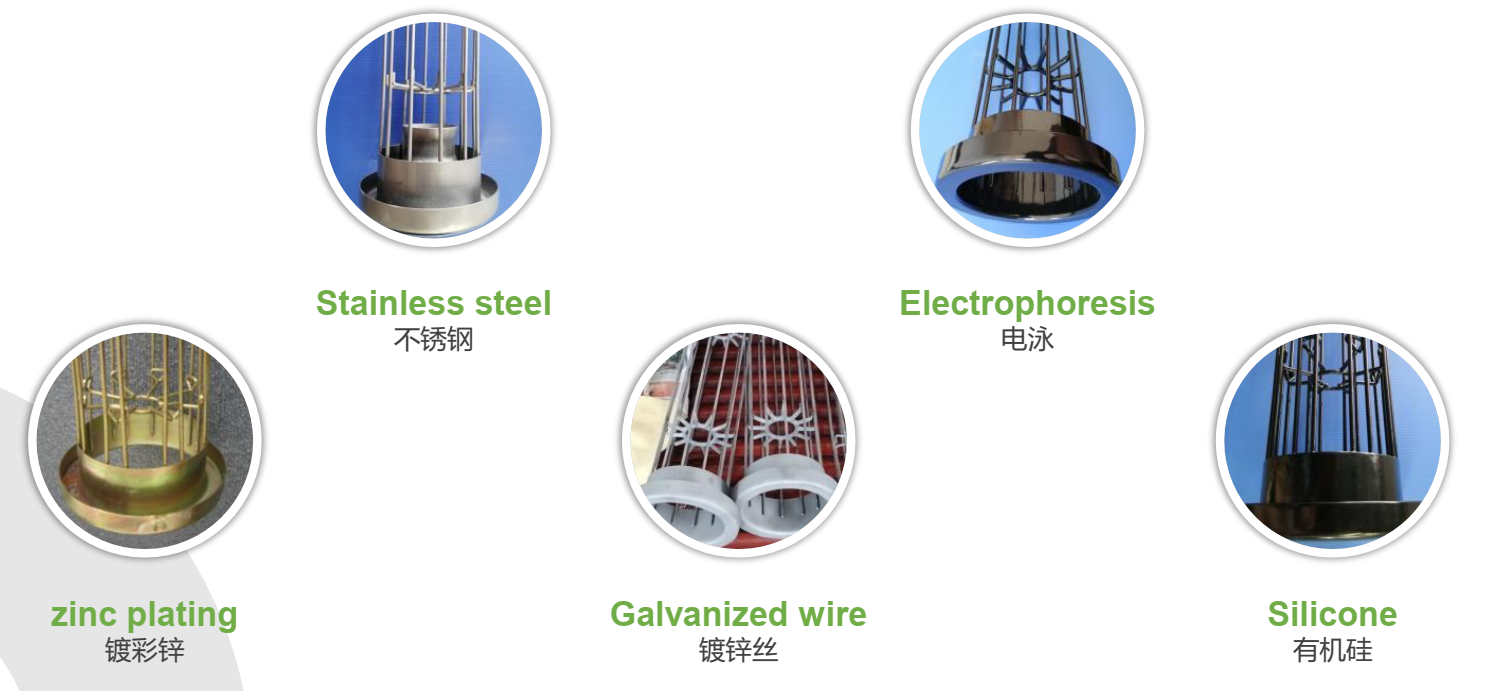

| Cage Material: | Stainless Steel,Carbon Steel, Galvanized Wire, |

| Cage Finish Treatment: | Silicon Coating, Zinc Coating, Electrophoresis Coating |

| Diameter: | 120mm, 130mm, 150mm, 155mm, 160mm |

| Bag Finishing: | Singeing, Calendering, Heat Setting, Anti-static, Water&Oil Repellent, PTFE Membrane, PTFE Impregnation and so on |

| Bag Head: | Seal Cuff, Bead Cuff |

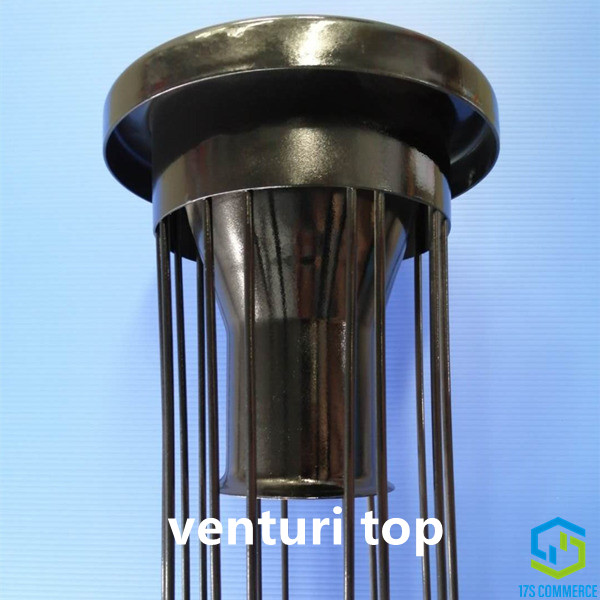

| Cage Top Cap: | Ordinary Cap, Venturi Top, Mikopul Cap, Hook Top, Ring Top, ETC |

| Cage Joint: | Twist Lock, Finger Lock, Slide Lock, Global Joint Lock |

| Cage Style: | Round, Oval cage, Star/ Pleat cage |

PTFE Dust Filter Bags And Cages PTFE Star Bag And Star Cage Bag

House PTFE Dust Collect Round Bag And Cage

Bags

1. Specification

Polytetrafluoroethylene is made from the monomer tetrafluoroethylene by free radical vinyl polymerization. PTFE is perhaps the most inert, chemically resistant, and temperature resistant polymer used in industrial filtration. Its characterizes are as follows:

100% PTFE bag is mainly used in chemical industry, waste incineration, high temperature resistant liquid filtration, keeps good chemical stability in the complex condition.

Finish Treatment: Singeing, Calendering, Heat Setting, Anti-static, Water&Oil Repellent, PTFE Membrane, PTFE Impregnation and so on

Bag Style: round bags, oval bags, 8 and 12 star/ pleats star bags

Bag Size: it is up to the CPO and installation and customized

Bag Head: seal cuff / groove snap / felt strip, bead cuff/ steel strip, etc

can be chosen

Bag Body: Sewing or Hot sealing

Bag Bottom: Single or double bottom, with reinforcement or without

reinforcement

Construction of Filter Bags

| Style | Size | Felt/ Fabric | Body | Head | Bottom Layer | Reinforcement |

| Round, Oval, Star/pleat | Customized | Various | Sewing or Hot Sealing | Seal Cuff, Bead Cuff | Single Or Double | With Or Without |

2. Parameters of PTFE Filter Bags

| Bag | PTFE Filter Bag | |||||

| Felt | PTFE Needled Felt | |||||

| Scrim | PTFE or P84 | |||||

| Weight | gsm | 700-750 | ||||

| Permeability | cfm | 20-30,PTFE lamination 3-7 | ||||

| Tensile Strength | Warp | ≥N | 450 | |||

| Weft | ≥N | 450 | ||||

| Break Elongation | Warp | < % | 25 | |||

| Weft | < % | 40 | ||||

| Working Temperature | Continuous | Dry | ℃ | 260 | ||

| Moist | ℃ | 260 | ||||

| Short term | ℃ | 290 | ||||

| Dry Shrinkage | Warp | <% | 1.5 | |||

| Weft | <% | 1.5 | ||||

| Specific Density | 2.3 | |||||

| Support Combustion | no | |||||

| Resistance | Hydrolysis | excellent | ||||

| Biological (mildew, bacteria) | no effect | |||||

| Alkalis | excellent | |||||

| Mineral Acids | excellent | |||||

| Orgnic Acids | excellent | |||||

| Oxidising Agents | excellent | |||||

| Orgnic Solvents | excellent | |||||

| Finishing | singeing, calendaring, oil and water proof, PTFE impregnation coating, PTFE lamination etc | |||||

Cages

1. Specification

Cages are frameworks for bags, which is the bone of bags and

supports the bags running. Both bags and cages are the most

important element for bag houses. Star Cages are welded by special

supporting rings (Spiders). We have own stretch line, cut line,

weld line, coating line and check equipment. Providing a wide range

of star filter cages for bag house collector, which improve the

performance, efficiency and bottom line of the bag house dust

collector and flue.

2. Procedure of cage making

| 1 | stretch line | streth 6 or 6.5 raw wire to roll diameters wires for cages, normally 3mm, 3.5mm and 4mm, |

| 2 | cut line | cut roll wires to fixed length based on cage sizes |

| 3 | weld body | weld vertical wires and suppoting ring together |

| 4 | weld top and bottom cap and venturi | weld top and bottom cap to cage, venturi if necessary |

| 5 | coating | silicon or zinc coating if necessary |

| 6 | inspect and fix | inspect weld loose, burs, coating etc and fix |

| 7 | pack | put cages into steel crates |

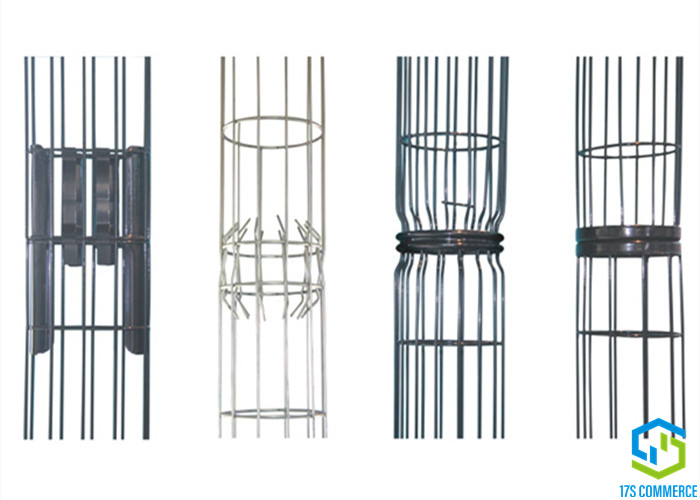

3. Cage Style: round cages, oval cages and pleats star cages

4. Construction of cages

| style | Vertical Wire QTY | Diameter of Wire | Supporting Ring | Top Cap | Bottom Cap | Connection |

| round cage | 8-24 | 4 / 3.5 /3.2 /3 | wire, round | optional | weld, crimp, wire bent | twist lock, sure lock, finger lock |

| oval cage | 10, 14 | 4 | wire, oval | oval | weld | slide lock |

| star/ pleat cage | 8,10, 12, 16 | 4 | press, wire | optional | weld or wire bent | global joint |

Optional Material: carbon steel, galvanized wire, stainless steel

Cage Diameter: customized

Cage Finish Treatment: silicon coating, zinc coating, electrophoresis coating

Cage Head: normal top cap, venturi top cap, split top (Mikropul) cap, wires

bent (hook) top, enlarged top ring etc

Cage Connection: cages were too long or top space of bag house was not enough, we suggest make cages in sections with joint like below

5. Installation on site

|