| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Die Casting Parts |

|---|---|

| Brand Name: | JHPD |

| Model Number: | BGFA |

| Certification: | IATF16949 |

| Place of Origin: | CHINA |

| MOQ: | 500PCS |

| Price: | Negotiable |

| Payment Terms: | T/T |

| Supply Ability: | 10000 pcs per month |

| Delivery Time: | 20-30 days |

| Packaging Details: | PP Bag, Paper Roll, Blister Box, Carton or According to Your Demand |

| Material: | Aluminum Alloy |

| Usage: | Monitor Housing Parts |

| Process: | Die casting |

| Surface treatment: | Powder coating |

| Cavity: | 1*1 |

| Tolerance: | +/-0.01 mm |

| Specification: | Customized |

| Mold life: | 30K |

| Transport Package: | Carton with pallet |

| Company Info. |

| Shenzhen Johnhalm PDTec.,Ltd |

| View Contact Details |

| Product List |

Powder Coating Alluminum Monitor Housing Cabinet Cover Die Casting Parts For Outdoors

Product Specification

| Material | Aluminum alloy: ADC12, ADC10, A360, A380, A356, 6061, 6063 Magnesium alloy: AZ91D, AM60B, Zinc alloy: ZA3#, ZA5#, ZA8# |

| Processing Craft | Drawings→ mould making → die casting →rough machining → CNC machining→surface treatment →product checking→ packing →delivery |

| Tolerance | ± 0.01mm |

| Surface Treatment | Electroplating, Chrome Plating, Zinc Plating, Nickel plating, Electrophoresis, Anodization, Polishing, Sandblasting, Passivation, Powder coating, Spray painting, Etc. |

| Quality Assurance | ISO9001:2015 Certified, IATF 16949, SGS Certification |

| Quality Guarantee | Two years |

| Inspection | 1. Foundry in-house: 100% inspection on critical dimension; 100% on

appearance. 2. Third Party inspection available upon requirement |

| Mainly Testing Facility | Three-dimensional measuring instrument (CMM), Salt spray test box, Dynamic balance detector, Pneumatic detection |

| Application | 3C industry, lighting decoration, electrical appliances, auto parts, furniture parts, electric tool, medical equipment, intelligent automation equipment,other metal casting parts. |

Equipment list

Ka Heng Mould Manufactruring Limited Shenzhen Johnhalm PDTec.,ltd | ||||

| No | Equipment name | Brand | Qty | Specification |

| 1 | Hot Chamber Die Casting Machine | LK | 1 | 88T |

| Hot Chamber Die Casting Machine | LK | 1 | 160T | |

| 2 | Cold Chamber Die Casting Machine | LK | 1 | 500T |

| Cold Chamber Die Casting Machine | LK | 2 | 280T | |

| Cold Chamber Die Casting Machine | LK | 1 | 500T | |

| Cold Chamber Die Casting Machine | LK | 1 | 800T | |

| Cold Chamber Die Casting Machine | LK | 1 | 1250T | |

| 3 | CNC lathe Machine | TSUGAMI CHINA | 5 | |

| 4 | CNC Machining Centre | Brother and Taikan | 16 | |

| 5 | Milling Machine | FTM-4TA | 4 | |

| 6 | EDM Machine | CKEATE450 | 2 | |

| 7 | Radial drilling machine | Z3038X9 | 1 | |

| 8 | Grinding Machine | M618A | 3 | |

| 9 | Drilling Machine | SGM350 | 10 | |

| 10 | Tapping Machine | Z3038X9 | 10 | |

| 11 | Ultrosonic Machine | 1 | ||

| 12 | Sand Blast Machine | MQ3225 | 2 | |

| 13 | Lapping Machine | 2 | ||

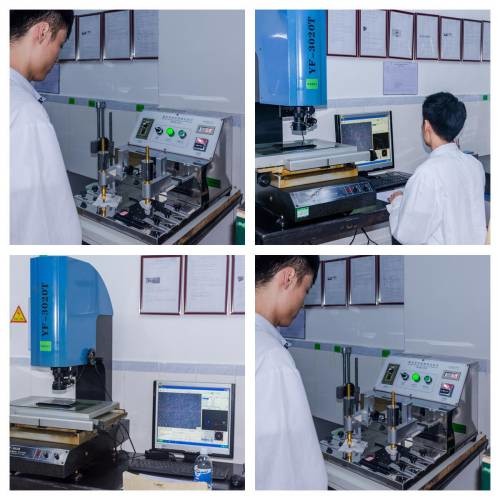

Inspection Equipment

| Shenzhen JiaHeng Mould Manufacture Co., Ltd Shenzhen Johnhalm PDTec.,Ltd | ||

| Main Inspection Equipment | ||

| No | Equipment name | Qty(pcs) |

| 1 | CMM | 1 |

| 2 | 2D measurement instrument | 1 |

| 3 | Infrared temperature detector | 1 |

| 4 | Thermocouple temperature detector | 1 |

| 5 | Image measuring instrument | 1 |

| 6 | Thickness meter | 1 |

| 7 | Roughness tester | 1 |

| 8 | Gloss tester | 1 |

| 9 | Salt spray test machine | 1 |

| 10 | Leeb hardness tester | 1 |

| 11 | Color difference analyzer | 1 |

| 12 | Wear test machine | 1 |

| 13 | Torque wrench | 1 |

| 14 | Micrometer | 6 |

| 15 | Caliper | 12 |

Company Profile

Our manufacturing capabilities and service consist of Die-casting, CNC machining, turning, milling, related mold and surface coating. We have enough advanced Equipment and instruments to support our production, such as 5 sets of die casting machines( 88T-1250T LK group ), 20 sets of CNC milling machines(Brother brand), 5 sets of CNC lathe machines etc.

Our products are abroad applied for various design and sizes parts

of industrial and household hardware such as electrical appliances,

machinery hardware, communication, LED housing,auto parts,etc.

We have passed ISO9001: 2008 and IATF16949, also obtained relevant

certificates.It's very safe to sale across the world. Welcome your

inquiry.

Each product are carefully inspection from the blank to the finished.Customer satisfaction is our eternal pursuit.

1.Regularly scheduled dimensional production checks using the

latest in applicable measuring technology

2.Complete customer-owned tooling maintenance program.

3.In-house Continual Improvement Team, which uses customer and

company feedback to constantly increase our effectiveness in meeting or exceeding our customers' demands.

Die casting workshop

Inspection Room

FAQ

1. How can I get the quotation?

Please send us the drawing, quantity, weight and material of the

product.

2. What kind of file can you read?

PDF, IGS, DWG, STEP,etc...

3. What is your way of packing?

Normally we pack goods according to customers' requirement.

For reference: wrapping paper, carton box, wooden case, pallet.

4. When can I get the samples and your main order time?

For samples: 25-35 days after start to make mold.

For order:30 days, the accurate time depends on product.

5. What's your payment term?

1)Tooling cost 50% deposit and 50% after T1 samples approved.

2) Parts cost Net30

3) Payment Method: Wire

|