| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Edge Lipping Machine |

|---|---|

| Brand Name: | HOLD |

| Model Number: | HD626JP |

| Place of Origin: | Guangdong China |

| Delivery Time: | 45 Days |

| Certification: | CE |

| MOQ: | 1 Set |

| Price: | Negotiable |

| Packaging Details: | Poly Wrapping Or Wood cases |

| Payment Terms: | LC/ TT |

| Supply Ability: | 10 Set / Month |

| After-sales service provided: | Video technical support,Field maintenance and repair service,Field installation,commissioning and training |

| Type: | Automatic electric |

| Control system: | Delta Inverter,computer servo motor,PLC automatic control,PLC |

| Voltage: | 220V/380V/440V/415V |

| Working pressure: | 0.6Mpa |

| Feeding speed: | 14-20-23m/min |

| Company Info. |

| Foshan Hold Machinery Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Woodworking Edge Banding Machine, All Intelligent Control System, Narrow Panel Edge Bander, Narrow Panel ≥45mm

Narrow panel edge bander

It is an edge bander for customized furniture companies, especially for machining narrow panels with a width of 35mm-60mm. It can replace the manual processing mode of narrow panels, solving the problem of narrow panel edge banding in factories.

The equipment adopts PUR gluing system. The PUR gluing perfectly solves the traditional "glue line" problem of edge banding. The gluing layer is thinner, the glue line more delicate, the adhesion effect and the edge banding effect better.

1. For the narrow end of the workpiece, the specially designed pre-milling mechanism can mill the end of the narrow panel ≥45mm.

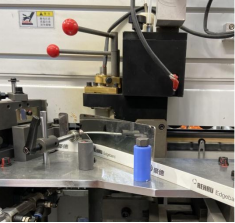

2. Auxiliary feeding of narrow side end: It is specially equipped for narrow-side ends edge banding. The feeding will not be off-track, and the feeding will be convenient, safe, and efficient.

3. Narrow side automatic side pressing device: Specially equipped for long panels with narrow side edge banding. The feeding will not be off-track, and the feeding will be fast and safe.

4. Electric press beam lifting reduces labor intensity and improves efficiency and accuracy.

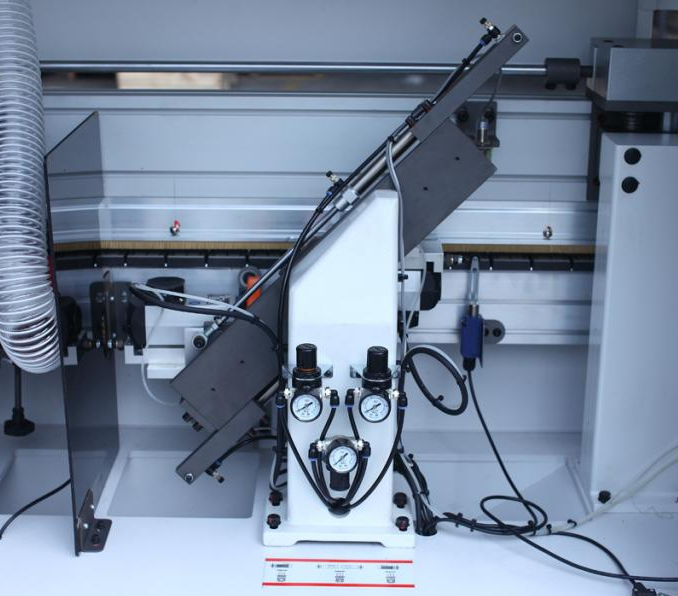

5. PUR gluing system: The glue layer is thinner and the edge banding effect is more delicate, which perfectly solves the traditional edge banding "glue line" problem. The fast glue discharge function makes you worry-free when using PUR glue.

6. Four pressing wheels with the enlarged diameter and four air cylinders ensure that the edge band is tightly pressed on the workpiece;

7. Conveyor reducer adopts a high-efficiency harden gear reducer, which is powerful.

8. Equipped with cleaning device and separation device.

Technical Parameters

Model | HD626JP | Model | HD626JP |

Lifting | Electric lifting | Panel thickness | 10-60mm |

Total power | 15.5kw | Edge thickness | 0.4-3mm |

Machine size | 7275x900x1700mm | Working pressure | 0.6Mpa |

Feed speed | 14-20-23m/min | Min.panel size | 300mm*45mm |

Narrow end width ≥45mm. Machining with the single pre-milling cutter, it can machine width ≥45mm.

Configuration instructions

| Control System 1-Current and voltage display 2-Banding with pre-delivery function 3-IO intelligent monitoring 4-Inverter fault code display 5-Automatic counting of edge banding 6-Inverter intelligent monitoring 7-Friendly smart interface |

| Auxiliary feeding of narrow side end It is specially equipped for narrow-side ends edge banding. The feeding will not be off-track, and the feeding will be convenient, safe, and efficient. |

| Automatic side pressing device Specially equipped for the long side with narrow side edge banding. The feeding will not be off-track, and the feeding is convenient and safe. |

| Electrical beam lifting Touch screen control eliminates the trouble of manual height adjustment. |

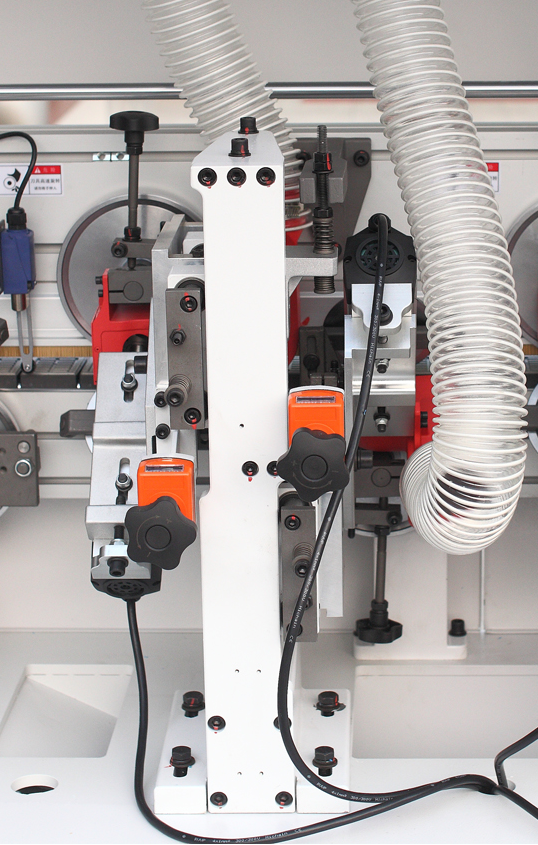

| Pre-milling It can be controlled independently, and can mill ≥45mm panels; After milling by the milling mechanism, various defects on the machined surface can be removed, and the edge banding can reach the best condition. |

| Separation device It has the function of separation and solves the problem of glue contaminating the board surfaces. |

| Heating unit When the temperature is low, heat the surface where glue is attached before gluing so that the glue will be attached securely and edge banding will be optimal. |

| PUR gluing unit The glue layer is thinner and the edge banding effect is more delicate, which perfectly solves the traditional edge banding "glue line" problem. The fast glue discharge function makes you worry-free when using PUR glue. |

| PUR glue injection machine (20KG) (optional) Ensure that the PUR glue is melted in advance during high-speed operation, and the glue is supplied in time. |

| Glue removal unit Strong pressing force, fit edge banding, removing residual hot melt adhesive on board to minimize glue thread and make edge banding optimal. |

| Rubber-coating auxiliary roller It does not damage the surface of the board. The narrow board runs stably on the conveyor belt, and the edge banding is stable. |

| A small press wheel with a diameter of 38mm is adopted to realize the three-point compression for the narrow panels, which makes the feeding of narrow panels stabler and improves the quality of edge banding. |

| End cutting Quickly cut the front and back edge banding. The two saw blades are matched back and forth to achieve high precision and high efficiency. |

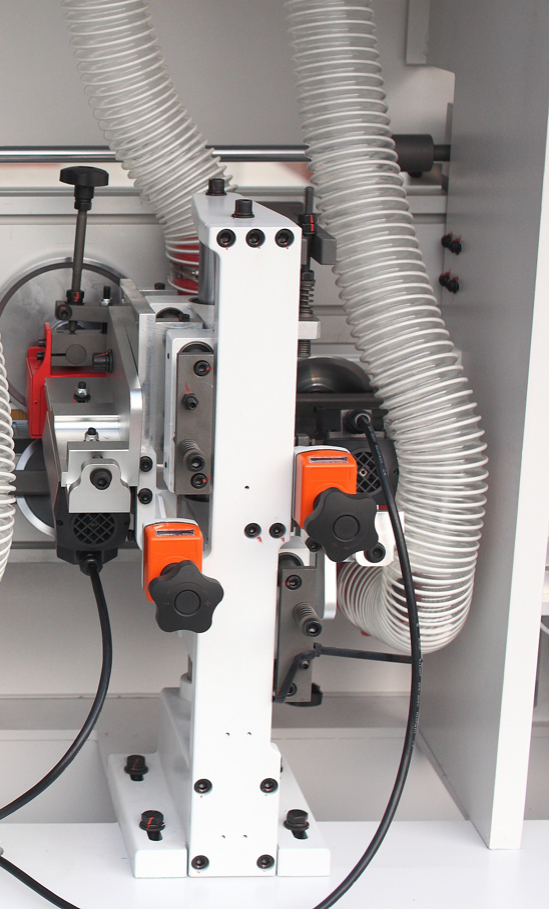

| Rough trimming Using two 1.1kw increased power motors, it cuts the upper and lower edges of the edge banding strip quickly and neatly to make the edge banding effect better. |

| Fine trimming Cutting and shaping the excess edge on the upper and lower panel and trimming into an R-angle shape, the upper and lower edges will be flat to the panel and smooth. |

| Corner rounding The corner rounding (chamfering) makes the four corners of the panel round and beautiful. |

| Scraping Remove the knife marks left by the trimming knife and ensure the edge surface smooth and beautiful. |

| Cleaning device Dilute the residual glue and make it easier to clean. |

| Buffing Erasing excess glue marks,it makes the edge banding smoother and cleaner. |

| Harden geared motor 4.0kw power, stable operation. |

| Unique design: Rubber-clad wheel The front and rear auxiliary rollers are equipped with rubber-covered rollers to prevent scratches. |

| For panel thickness 9mm Narrow end width ≥45mm. Machining with the single pre-milling cutter, it can machine width ≥45mm. |

|