| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Waste Tyre To Oil Pyrolysis Plant |

|---|---|

| Brand Name: | Jinzhen |

| Model Number: | HNJZ-15 |

| Certification: | CE |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | USD 55000 per set |

| Payment Terms: | T/T, Western Union, L/C |

| Supply Ability: | 18 Set/Sets per Month |

| Delivery Time: | 25 days |

| Packaging Details: | 40’FR for pyrolysis reactor , the rest parts of the machine shipped by 40’ HQ |

| Type: | waste tire pyrolysis plant,Waste Tyre Pyrolysis Machine |

| Raw material: | waste tyre, rubbers, tire scrap |

| Capacity: | 15ton per day, 15ptd |

| End product: | Tyre Oil, Carbon Black, Steel Wire |

| Usage: | fuel oil as heating material |

| Power: | 25 kW |

| Reactor Material: | Q345R, Cr12 Alloy Steel, Stainless Steel |

| Reactor Thickness: | 14mm, 16mm,18mm,20mm |

| Machine Testing: | X- Ray and Pressure Testing |

| Output: | 40-45% Fuel Oil |

| Factory Area: | L*W*H=30m*10m*7m |

| Warranty: | 2 years |

| After-Sale Service: | Installation, Training and Debugging |

| Company Info. |

| Henan Jinzhen Boiler Co., Ltd. |

| View Contact Details |

| Product List |

30T-50T Batch Type Waste Tyre Oil Pyrolysis Plant For Recycling Used Tire

waste tire rubber pyrolysis method can pyrolysis the raw materials of the waste tire rubber, so that the waste tire rubber can exert its own value, and then the waste is not waste. After the pyrolysis reaction, fuel oil, carbon black, steel wire, non-condensable but flammable gas can be obtained. The pyrolysis equipment is divided into batch type, continuous type, two-to-one type, multi-group type, etc. If you want to know what kind of product is best for you

Feeding 2 hours —— Pre-heating 2-3 hours —— Oil Producing 8-10hours—— Cooling 3-4 hours —— Carbon black discharging 2 hours —— Steel Pulling 0.5 hour

Technical Specification

| Raw material | Waste rubbers/tyres/plastic | Waste rubbers/tyres/plastic | Waste rubbers/tyres/plastic | Waste rubbers/tyres/plastic |

| Daily Handling capacity | 5 tons | 8 tons | 10 tons | 12 tons |

| Working pressure | Normal pressure | Normal pressure | Normal pressure | Normal pressure |

| Main engine rotating speed | 0.4R /min | 0.4R /min | 0.4R /min | 0.4R /min |

| Power | 15KWH | 15KWH | 15KWH | 15KWH |

| Cooling Mode | Water | Water | Water | Water |

| Floor Area | 200m2 | 250m2 | 300m2 | 300m2 |

| Heating Mode | Direct | Direct | Direct | Direct |

| Oil Yield | 45%-50% | 45%-50% | 45%-50% | 45%-50% |

| Noise dB (A) | <=85 | <=85 | <=85 | <=85 |

| Machine dimension(mm) | D2200*L5000 | D2200*L6600 | D2600*L6600 | D2800*L6600 |

| Working Mode | Intermittence | Intermittence | Intermittence | Intermittence |

Advantages of Waste Tyre Pyrolysis Plant

1.Outstanding Features:

a. The reactor need preheat at the first when the machine starts

producing.

b. 24h continuous working for 20-30 days without any stops.

c. No need fuels, sync gas is recycled during the operation.

d. Large daily capacity:20-25T/D;25-30T/D

e. New desing of vertical condensers. Good oil quality with high

profit.

f. Low requirement on the raw materials.

2. Security:

a: Adopting automatic submerged-arc welding technology

b: All of the welding will be detected by the ultrasonic

nondestructive testing method to ensure the welding quality and the

welding shape.

c: Adopting manufacture process controlling system on the quality,

every manufacture process, manufacture date, etc.

d: Equipped with anti-explosion device, safety valves, emergency

valves, pressure and temperature meters, as well as the alarming

system.

3. Environmental-friendly:

a: Emission Standard: Adopting special gas scrubbers to remove acid

gas and dust from smoke

b: Smell during operation: Fully enclosed during the operation

c: Water pollution: No pollution at all.

d: Solid pollution: the solid after pyrolysis is the crude carbon

black and steel wires which can be deep-processed or sold

directly with its value.

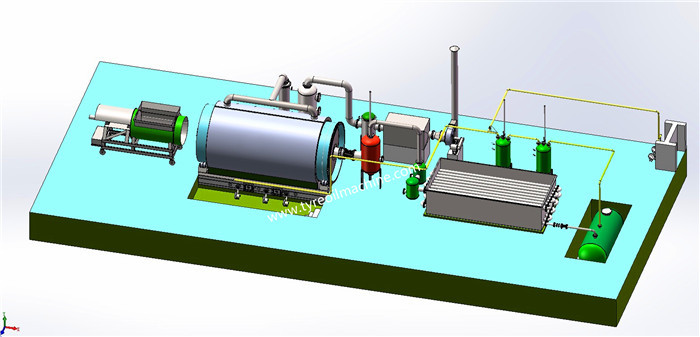

Picture Details for tyre pyrolysis machine

|