| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Troughed Belt Conveyor |

|---|---|

| Brand Name: | JINRUI |

| Model Number: | TD75-800 |

| Certification: | ISO |

| Place of Origin: | Henan |

| MOQ: | 1 piece |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50 piece per Month |

| Delivery Time: | 10-12 work days |

| Packaging Details: | accroding to the machine size packed into different size woodcase |

| Product Name: | Low Maintenance Transporter Rubber Trough Belt Conveyor |

| Belt Width: | 800mm |

| Type: | Troughed Belt Conveyor |

| Frame material: | Carbon Steel |

| Material feature: | Heat Resistant |

| Application: | Bulk material |

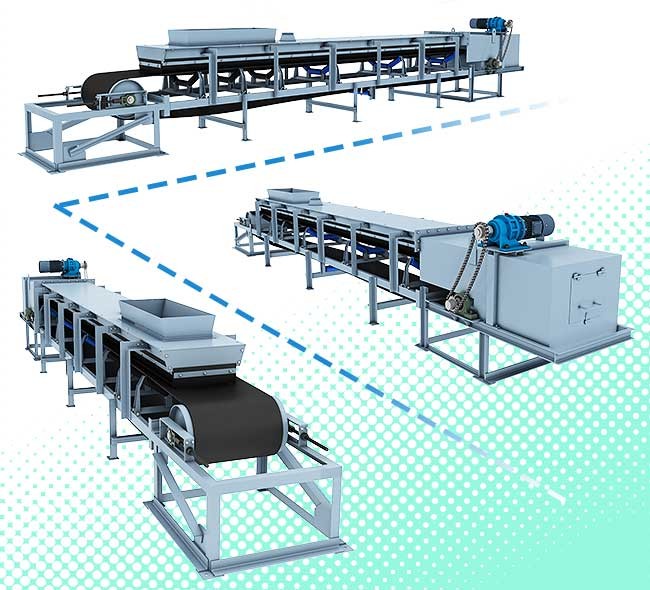

TD75 Inclined Troughed Power Belt Conveyor is a general-purpose belt conveyor, used in metallurgy, coal, mining and other departments. Various bulk and granular materials with a specific gravity of 0.5 to 2.5t / m3 can be conveyed, which can be used to convey articles. The applicable working environment temperature is between -15 ° C and 40 ° C; it can also be used for horizontal chemical material transportation. Determine the angle of inclination according to the nature of the material when conveying obliquely upward.

Inclined Troughed Power Belt Conveyor is composed by two endpoint pulleys and a closed conveyor belt. The pulley that drives conveyor belt rotating is called drive pulley or transmission drum; the other one–only used to change conveyor belt movement direction–is called bend pulley. Drive pulley is driven by the motor through reducer, and conveyor belt dragging relies on the friction drag between the drive pulley and the conveyor belt. The drive pulleys are generally installed at the discharge end in order to increase traction and be easy to drag. Material is fed on the feed-side and landed on the rotating conveyor belt, then rely on the conveyor belt friction to be delivered to discharge end.

Inclined Troughed Power Belt Conveyor is mainly composed of several major components, such as a driving device, a transmission roller, a redirecting roller, a conveyor belt, a roller component, a tensioning device, a supporting member, and a safety protection device. The features are below:

1. Easy loading and unloading. The belt conveyor can be loaded and unloaded at any point according to the needs of the process.

2. Strong adaptability to the line. The conveying line can be horizontal or inclined, or it can be bent horizontally or vertically, so it is less restricted by terrain conditions.

3. High reliability. Due to the simple structure and the light weight of the moving parts, as long as the conveyor belt is not torn, the service life can be as long as ten years, and the metal structural parts will not be damaged for decades if they are rust-proof.

4. Less maintenance costs. The moving parts of the belt conveyor are only rollers and idlers, and the conveyor belt is very wear-resistant. Compared to other conveying machines, there are far fewer wear parts.

In addition, the belt conveyor also features low operating costs, low capital investment, low energy consumption, and high efficiency.

Material to be processed: _____

Handling capacity:_____

Bulk Density: _____t/m3

Material temperature: _____℃

Water content:____%

Material is corrosive or not: ____

Material is sticky or not: ____

Working environment temperature: ______ ℃

Working voltage:____V_____hz_____phase

| Belt Width | Section Form | Speed | Max Capacity |

| 800mm | Though | 1.0m/s | 278t/h |

| 1.25m/s | 348t/h | ||

| 1.6m/s | 445t/h | ||

| 2.0m/s | 546t/h | ||

| Flat | 0.8m/s | 118t/h | |

| 1.0m/s | 147t/h | ||

| 1.25m/s | 184t/h | ||

| 1.6m/s | 236t/h | ||

| 2.0m/s | 289t/h |

|