| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Tile Adhesive Production Line |

|---|---|

| Brand Name: | MG |

| Model Number: | MG-3.7 |

| Certification: | CE, ISO, SGS,BV |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | USD30000-60000/SET |

| Payment Terms: | T/T, L/C, Western Union, MoneyGram |

| Supply Ability: | 30 sets per month |

| Delivery Time: | 20-25 working days from paid advace payment |

| Packaging Details: | Standard seaworthy packing-Wooden box packing and bubble wrap packing |

| Product name: | Full Automatic Dry mortar mixing equipment |

| Raw material: | Cement, Sand, Flyash, Calcium carbonate, Lime powder and additives |

| Control system: | Intelligent PLC and computer control |

| Warranty: | 1 Year |

| Dimension(l*w*h): | Working Site |

| Capacity: | 10-12t/h |

| Workshop height: | 9-12m |

| Machine Color: | Can be print as customer requirement |

| Voltage: | 220V-440V, 50/60Hz Customize |

| Application: | Dry mortar mixing production |

| Company Info. |

| Zhengzhou MG Industrial Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Tile Adhesive Tile Glue High Intelligent Full Automatic Dry Mortar Premixing Machine

1. What is Dry mortar:

Dry mortar mainly refers to the blended masonry mortar, plastering mortar and floor tile mortar all for building construction and interior and exterior applications. Dry mix mortar or dry powder mortar is a kind of mixed product made by means of admixing the additives materials together with the dried and screened sand, cement, and fly ash in proportion.

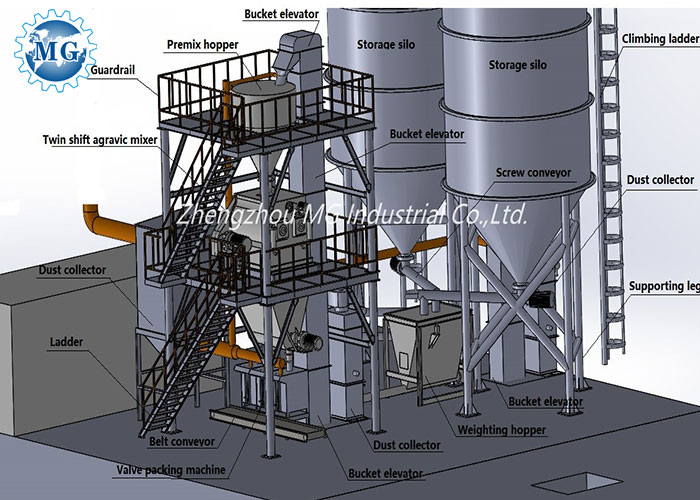

MG series tile adhesive machine is based on the latest design concept in Europe, this production adopts the advanced computer auto-control system, which production capacity can reach 30-100 thousand tons per year depend on the system configuration. The production line consists of storage system, metering and batching system, conveying system, mixing system, air compressor system, packaging system, and dedusting system, etc

2. Flow Chart of MG Full Automatic Dry Mortar Mixing Equipment:

3. Application of MG Full Automatic Dry Mortar Mixing Equipment:

Dry mix mortars are used in many different applications in the construction of a building. Some of these applications are universal and some others are specific to certain regions or countries. Dry Mortar Mixing Equipment can produce the following dry mortars:

| Bonding mortar | Masonry mortar, wall and floor tile adhesive mortar, anchorage mortar etc |

| Decoration mortar | Decorative plaster, inner and outer wall putty, colorful decoration mortar etc |

| Protection mortar | Water-proof mortar, anti-corrosion mortar, self-leveling mortar, wear resistance mortar, thermal insulation mortar, sound insulation mortar, repair mortar, mildewproof mortar, shielding mortar etc. |

| No. | Name | Model | |

| 1 | Raw Material Storage System | Detachable Silo | |

| 2 | Conveying System | I | Screw Conveyor |

| II | Indoor Bucket Elevator | ||

| III | Outdoor Bucket Elevator | ||

| 3 | Small additives &weighting system | Optional | |

| 4 | Batching & Weighing System | Batching & Weighing Hopper | |

| 5 | Mixing System | I | Double Shaft Paddle Mixer |

| II | Premix Hopper | ||

| III | End Product Hopper | ||

| 6 | Packing System | Automatic Robot Valve Port Packing machine | |

| 7 | Control System | PLC Control Cabinet | |

| 8 | Dedust Part | Pulse Dedust Filter | |

| 9 | High Pressure Air Supply | Air Compressor | |

| 10 | Steel Structure | 2-Layer Steel Platform | |

| 11 | Bag Belt Conveyor(Optional) | Roller type belt conveyor | |

| 12 | Cleaning and climbing conveyor | Dust Cleaning and climbing roller conveyor | |

| 13 | Production date printer | Production date printer | |

| 14 | Palletizing system | Palletizing machine | |

| 15 | wrapping system | wrapping machine | |

|