| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Industrial Ceramic Parts |

|---|---|

| Brand Name: | ZG |

| Model Number: | MS |

| Certification: | CE |

| Place of Origin: | CHINA |

| MOQ: | 1 piece |

| Price: | USD10/piece |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 10000 pieces |

| Delivery Time: | 5-8 working days |

| Packaging Details: | Strong wooden box for Global shipping |

| Material: | Graphite |

| Size: | Customized |

| Features: | excellent wear resistance; chemical inertness; no grinding in the product to be crushed; long service life |

| Color: | Black |

| Company Info. |

| HENAN ZG INDUSTRIAL PRODUCTS CO.,LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

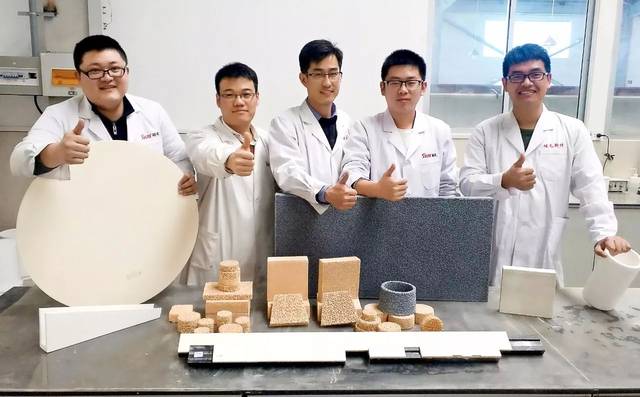

Industrial Ceramic Products For The Papermaking Industry

Industrial Ceramic Products For The Papermaking Industry with wear resistance

Ceramic parts are effective for separating foreign materials and dewatering.With their superior wear resistance, ceramics are used to create cleaner cones that separate foreign material from pulp slurry, suction box covers, and blades to dewater through a wire mesh, as well as flat parts and rollers to remove water from felt.

Related Data

| Main component | 99%Al2O3 | S-SiC | ZrO2 | Si3N4 | ||

| Physical Property | Density | g/cm3 | 3.9 | 3.1 | 6 | 3.2 |

| Water Absorption | % | 0 | 0.1 | 0 | 0.1 | |

| Sinter Temperature | °C | 1700 | 2200 | 1500 | 1800 | |

| Mechanical Property | Rockwell Hardness | HV | 1700 | 2200 | 1300 | 1400 |

| Bend Strength | kgf/mm2 | 3500 | 4000 | 9000 | 7000 | |

| Compression Intensity | Kgf/mm2 | 30000 | 20000 | 20000 | 23000 | |

| Thermal Property | Maximum working temperature | °C | 1500 | 1600 | 1300 | 1400 |

| thermal expansion coefficient 0-1000°C | /°C | 8.0*10-6 | 4.1*10-6(0-500°C) | 9.5*10-6 | 2.0*10-6(0-500°C) | |

| 5.2*10-6(500-1000°C) | 4.0*10-6(500-1000°C) | |||||

| Thermal Shock resistance | T(°C) | 200 | 250 | 300 | 400-500 | |

| Thermal Conductivity | W/m.k(25°C | 31 | 100 | 3 | 25 | |

| 300°C) | 16 | 100 | 3 | 25 | ||

| Electrical Property | Resisting rate of Volume | ◎.cm | ||||

| 20°C | >1012 | 106-108 | >1010 | >1011 | ||

| 100°C | 1012-1013 | – | – | >1011 | ||

| 300°C | >1012 | – | – | >1011 | ||

| Insulation Breakdown Intensity | KV/mm | 18 | semiconductor | 9 | 17.7 | |

| Dielectric Constant (1 MHz) | (E) | 10 | – | 29 | 7 | |

| Dielectric Dissipation | (tg o) | 0.4*10-3 | – | – | – | |

Due to such properties as:

ceramic materials are used in the papermaking industry for the production of the following products:

Basic material execution: zirconia (ZrO2), aluminum oxide (Al2O3), silicon nitride (Si3N4), various ceramic compositions.

|