| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

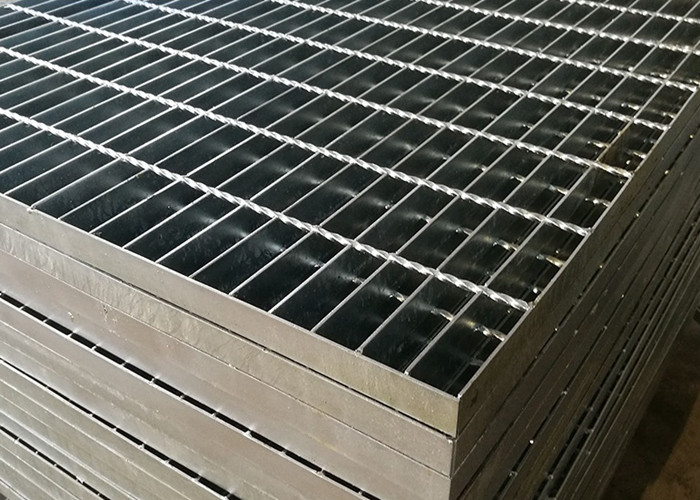

| Categories | Hot Dip Galvanized Steel Grating |

|---|---|

| Brand Name: | Jiongcan |

| Model Number: | JC-RD-023 |

| Certification: | ISO9001 |

| Place of Origin: | HeBei China |

| Phot Dip Galvanized Steel Gratingroduct name: | Hot Dip Galvanized Steel Grating |

| Special Use: | High-strength Steel Plate |

| Cross bar: | 6mm/8mm/10mm |

| Technique: | Welded Mesh |

| Flat bar type: | Serrated |

| Size: | Customer Size |

| Keyword: | steel grating |

| Plate Feature: | anti-corrosive,simple installation,light weight, |

| After-sale Service: | Online technical support, Onsite Installation, Onsite Training |

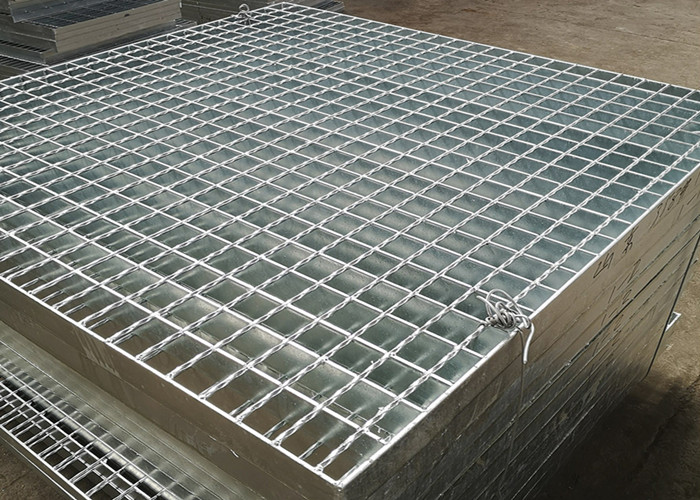

Hot dip galvanized steel grid plate is produced after the steel

grid, rust prevention treatment.

There are two kinds of hot dip galvanizing and electric

galvanizing.

Hot dip galvanized steel grid according to the manufacturing

process, divided into welding hot dip galvanized steel grid and

pressure lock hot dip galvanized steel grid;

According to the surface shape of hot dip galvanized flat steel, it

is divided into toothed hot dip galvanized, planar hot dip

galvanized, I hot dip galvanized and composite hot dip galvanized

steel grid.

The letter "G" for the hot dip galvanizing mark may be omitted from

the grating code.

Hot dip galvanizing implementation standard: GB/T 13912-2008.

Hot dip galvanized steel grid plate is the most widely used

products in steel grid plate, steel grid plate welded after hot dip

galvanized treatment, not only beautiful appearance, but also can

play a good role in corrosion prevention and rust prevention,

prolong service life, favored by the majority of customers.

Bearing bar | flat bar | serrated flat bar | I bar | Serrated I bar |

Crossing bar | Twisted rod | Twisted square bar | round bar | flat bar |

Bearing bar pitch | 30,40,50 | 30,40,50 | 30,40,50 | 30,40,50 |

crossing bar pitch | 30,50,100 | 30,50,100 | 30,50,100 | 30,50,100 |

1, flat steel spacing of 30mm hot dip zinc steel grid for the

industrial field of the most widely used varieties.

In the series of commonly used hot dip zinc steel grates, it has

the strongest resistance to surface impact.

The hot dip zinc steel grating is made of flat steel with width of

65mm - 200mm and thickness of 5mm - 20mm. It is suitable for large

cargo yards, docks, coal mines, roads, Bridges, etc., and can carry

large trucks through.

2, flat steel spacing of 40mm hot dip zinc steel grid for the most

economic, the most portable varieties.

It is the most ideal choice in the case of small span.

Suitable for all kinds of occasions, especially the walkway,

sightseeing platform, etc.

3, flat steel spacing for 60mm bar for 50mm hot dip zinc steel grid

plate is suitable for mining and mining to solve the problem of

mineral splashing on the surface of the plate, often designated for

mining processing plants.

Hot dip zinc steel grid plate is characterized by: high strength,

light structure;

The solid grid pressure welding structure makes it has the

characteristics of high load bearing, light structure, easy to

hoisting and so on;

Beautiful appearance, durable.

Acid and alkali corrosion ability: in the range of pH 6 to pH 12.5,

the zinc layer surface formed a stable protective film, good

corrosion resistance.

Hot Dip Galvanized Steel Grating Application

Applicable to alloy, building materials, power stations, boilers, shipbuilding, petrochemical, chemical and general industrial plants, municipal construction and other industries, with ventilation and light, anti-skid, strong bearing capacity, beautiful and durable, easy to clean, easy installation and other advantages.At present, steel grid plate has been widely used in all walks of life at home and abroad, mainly used as industrial platform, ladder pedal, bar, channel floor, railway bridge side road, high-rise tower platform, drainage ditch cover, manhole cover, road barrier, three-dimensional parking lot, organs, schools, factories.

Hot Dip Galvanized Steel Grating Advantages:

Widely used in petroleum chemical industry, tobacco industry, electricity, water, sewage disposal, port terminals, building decoration, shipbuilding, self-contained parking lot, municipal engineering, environmental sanitation engineering areas such as the platform, walkway, pier, trench cover, manhole covers, ladders, fences, stadium, exhibition center, large commercial, station, wharf, airport and other industrial and civil construction of condole top, etc.

Hot Dip Galvanized Steel Grating Process:

Steel plate process with manual welding process and welding machine

process, surface treatment of hot dip galvanizing and painting, the

composition of ordinary steel plate is made of flat steel and twist

steel welded together, is composed of flat steel welded with

special specifications, steel grid plate can be divided into common

flat steel and sawtooth toothed plates, serrated flat non-slip

effect is more outstanding.

The connection mode of steel grid plate is fixed and installed with

buckle connector, which is composed of three parts.

Hot-dip galvanized steel grid plate can be installed in two ways:

welding and clamping.The advantages of welding are permanent

fixation, not loosening, specific position in the first flat steel

at each corner of the steel grid plate, the length of the weld is

not less than 20mm, the height is not less than 3mm of fillet

welding.The advantages of the mounting clip are that it does not

destroy the hot dipping zinc layer and it is easy to disassemble.

Each plate needs at least 4 sets of mounting clips. The number of

mounting clips increases with the increase of the length of the

plate.The safest method is to weld the screw head directly to the

beam without clamping down, so that the steel grille plate will not

slip from the beam due to the loosening of the clamping.

Pre-sale service:

After the customer orders, we will have professional technical

personnel to contact with the customer, in order to meet the

customer's technical inquiry and production schedule.

|