| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | CNC Rotary Chuck |

|---|---|

| Brand Name: | Lingman |

| Model Number: | W400S-56 |

| Place of Origin: | Changzhou, Jiangsu, China |

| MOQ: | 1 set |

| Price: | USD 2600-3100/set |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 100 sets per month |

| Delivery Time: | 15-20 work days |

| Packaging Details: | Wood carton |

| Product name: | Main chuck |

| Raw material: | Stainless steel |

| Claw stroke: | 56mm |

| Maximum clamping force: | 13.5KN |

| Allowable pressure: | 0.4-0.9MPa |

| Limit speed: | 300r/min |

| Clamping range: | 20-400mm |

| Central height: | 300mm |

| Rotational inertia: | 5.6kg.㎡ |

| Rotating part weight: | 190kg |

| Whole unit weight: | 270kg |

| Company Info. |

| Lingman Machinery Technology (Changzhou) Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

1. Description

Our feeding chucks are also designed for laser pipe cutting machine which are also suitable for our main chucks. The chuck is in a solid structure and it is dual-power automatic two-two-center structure. It can be used to clamp the circular, square, rectangular, elliptical and other central axis symmetrical parts.

About the rapid clamping and loosening actions, they can be achieved by gyrator which is at the end of the product rotating air intake. And air source is continuously supplied when working. When fixing the chuck base, it only needs to connect connect the matched motor with the gear and compressed air source, the clamping and driving work-piece to rotate can be achieved.

Due to the long length of the parts processed by the cutting machine, the back chuck and matched main chuck are usually installed in pairs on the equipment.

2. Performance Parameters

| W400S-56 |

| 56mm |

| 13.5KN |

| 0.4-0.9MPa |

| 5300r/min |

| 20-400mm |

| 300mm |

| 5.6kg.m2 |

| 190kg |

| 270kg |

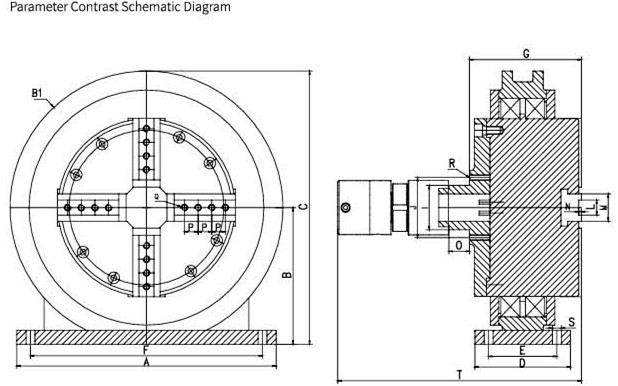

3. Dimensions

| Specifications | A | B | B1 | C | D | E | F | G | H | I | J | L | M | N | O | P | Q | R | S | T |

| W400S-56 | 525 | 300 | 578 | 589 | 180 | 135 | 475 | 223 | 0 | 100 | 130 | 20 | 45 | 4 | 30 | 30 | M12 | 8-M10 | 18 | 375 |

4. Advantages

| a. Full stroke design |

| b. Wide range of applications, diversification of processing profiles |

| c. High repetitive positioning accuracy |

| d. Low maintenance cost, long service life |

e. Multiple configurations are available e.2 Comb-type or mortise-groove type claws |

5. Production Line

6. Our Service

| a. We are the direct factory with good price and fast lead time. |

| b. Professional design team work with you. |

| c. Professional QC team to guarantee the high quality. |

| d. Providing OEM & ODM service. |

|