| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | 3 Color Molding |

|---|---|

| Certification: | ISO 9001,IATF 16949,ISO 13485, ISO 14001 |

| Plastic Material: | PP,ABS,PA66,PA6,PC,POM,PBT, PMMA, PPS, PPU,PPE,TPE, or other you want. |

| Plastic Surface finish: | Polishing finish,Texture Finish,Slik print, VDI-3400 |

| Drawing format: | UG, IGES, STEP,x_t, AutoCAD, Solidworks,Catia, PTC Creo, DWG, PDF, etc.. |

| Certificated: | ISO13485,IATF16949, ISO14001 |

| Range of markets: | medical,Industrial,automotive,electronics,aerospace,and others |

| Mould Material: | 2343, 2344, S136, 2085, 2738,M310,M333,W300,DC53,S-7, 8407, Unimax, Viking, SKD61, NAK80,H13,P20, 718,2767 |

| Hot runner: | Synventive, Incoe, HRS, moldmasters, HUSKY, EWIKON, Guenther,BHT |

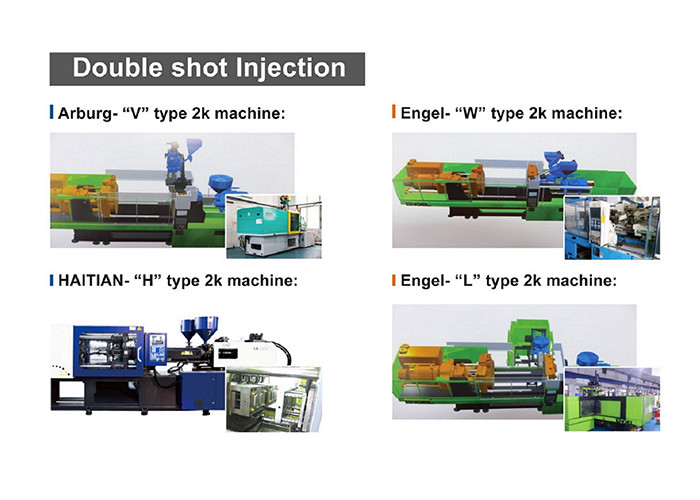

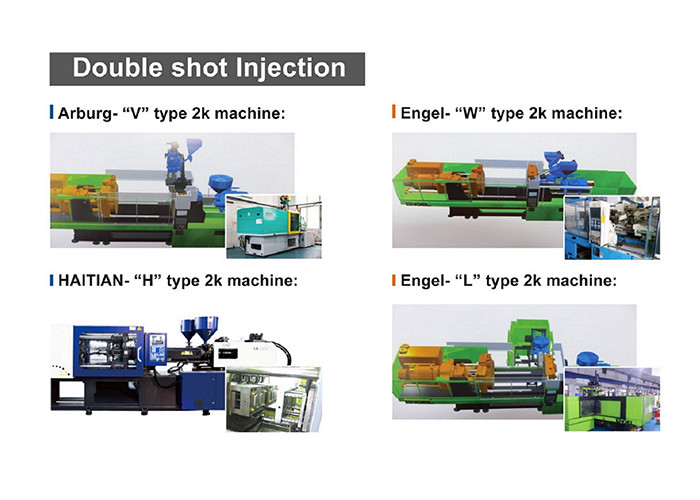

| Injection machine size: | 50T-1750T |

| Place of Origin: | China (Mainland) |

| Model Number: | customized |

| MOQ: | negotiable |

| Price: | negotiable |

| Packaging Details: | Carton packaging |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union |

2343, 2344, S136, 2085, 2738,M310,M333,W300,DC53,S-7, 8407, Unimax, Viking, SKD61, NAK80,H13,P20 2 Color Tooling & Parts

Plastic Material:PP,ABS,PC, TPE, PE, TPU, PPSU, PEEK, PEI, PBT, PA, LSR, ASA,POM,PCTG,PC/ABS

Plastic Surface finish:Polishing finish,Texture Finish,Slik print, VDI-3400,

Drawing format:UG, IGES, STEP,x_t, AutoCAD, Solidworks,Catia, PTC Creo, DWG, PDF, etc..

Certificated:ISO13485,IATF16949, ISO14001

Range of markets:medical,Industrial,automotive,electronics,aerospace,and others

Mould Material:2343, 2344, S136, 2085, 2738,M310,M333,W300,DC53,S-7, 8407, Unimax, Viking, SKD61, NAK80,H13,P20, 718,2767

Hot runner:Synventive, Incoe, HRS, moldmasters, HUSKY, EWIKON, Guenther,BHT

Injection machine size:50T-1750T

Cavities:1-64

Product Details

| Mold type | Plastic injection mold& molding |

| Mold type(molding life) | Prototype mold, Production mold |

| Design software | Auto CAD, UG, Pro-e, Solid works etc |

| Resin(plastic material) | ABS,PP,PC,PE,PA66,Pa66+GF, PPS, POM, PVC,PET,PEEK,PMMA,TPE... |

| Mold base | LKM, DME, etc. |

| Steel | 718H, P20, NAK80, SKD61Heat hard, H13 Heat hard , S136 heat hard, 420(heat hard) 8407(heat hard), Cr12, CrWMn ,etc. |

| Runner type | cold runner, hot runner, hot manifold |

| Cavity type | single, family, multi-cavity |

| Hot runner | YUDO, Mold master, Incoe, Husky, etc. |

| Surface treatment | polishing, texture |

| post processing | painting, chrome plating, etc. |

| Package | Plastic bag, carton |

| Shipping | by sea, by air, by express, etc. |

FAQ

Q. I have an idea for a new product, but don't know if it can be

manufactured. Can you help?

A. Yes! We are always happy to work with potential customers to

evaluate the technical feasibility of your idea or design and we

can advise on materials, tooling and likely set-up costs.

Q. What are the advantages to having my parts manufactured locally?

A. Longeron can offer quick reaction times to any changes in

specification, batch size or material. We can ship small or large

quantities anywhere in Europe overnight to accommodate unforeseen

changes in demand.

Q. My components have already been developed on CAD. Can you use

the drawings?

A. Yes! DWG, DXF, IGES, Solidworks and Rhino files can all be used

to generate quotes, models and mould tools - this can save time and

money in producing your parts.

Q. Can I test my idea/component before committing to mould tool

manufacture?

A. Yes, we can use CAD drawings to make models for design and

functional evaluations.

Q. What type of plastic is best for my design/component?

A. Materials selection depends on the application of your design

and the environment in which it will function. We will be happy to

discuss the alternatives and suggest the best material.

Q. What type of mould tool do I need?

A. Mould tools can be either single cavity (one part at a time) or

multi-cavity (2, 4, 8 or 16 parts at a time). Single cavity tools

are generally used for small quantities, up to 10, 000 parts per

year whereas multi-cavity tools are for larger quantities. We can

look at your projected annual requirements and recommend which

would be best for you.

Q. Ok, I've decided to go ahead with my project. How long will it

take to get my parts?

A. It can take 3-6 weeks to have the mould tool manufactured

depending on the part's complexity and the number of impressions

(single or multi). After we have received final approval by you of

the new tool, you can expect delivery of parts within 3-5 days.

Q. I have an idea for a new product, but don't know if it can be

manufactured. Can you help?

A. Yes! We are always happy to work with potential customers to

evaluate the technical feasibility of your idea or design and we

can advise on materials, tooling and likely set-up costs.

Q. What are the advantages to having my parts manufactured locally?

A. Longeron can offer quick reaction times to any changes in

specification, batch size or material. We can ship small or large

quantities anywhere in Europe overnight to accommodate unforeseen

changes in demand.

Q. My components have already been developed on CAD. Can you use

the drawings?

A. Yes! DWG, DXF, IGES, Solidworks and Rhino files can all be used

to generate quotes, models and mould tools - this can save time and

money in producing your parts.

Q. Can I test my idea/component before committing to mould tool

manufacture?

A. Yes, we can use CAD drawings to make models for design and

functional evaluations.

Q. What type of plastic is best for my design/component?

A. Materials selection depends on the application of your design

and the environment in which it will function. We will be happy to

discuss the alternatives and suggest the best material.

Q. What type of mould tool do I need?

A. Mould tools can be either single cavity (one part at a time) or

multi-cavity (2, 4, 8 or 16 parts at a time). Single cavity tools

are generally used for small quantities, up to 10, 000 parts per

year whereas multi-cavity tools are for larger quantities. We can

look at your projected annual requirements and recommend which

would be best for you.

Q. Ok, I've decided to go ahead with my project. How long will it

take to get my parts?

A. It can take 3-6 weeks to have the mould tool manufactured

depending on the part's complexity and the number of impressions

(single or multi). After we have received final approval by you of

the new tool, you can expect delivery of parts within 3-5 days

|