| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Electroplating Barrel |

|---|---|

| Brand Name: | surplus |

| Model Number: | Barrel-019 |

| Certification: | ISO9001 |

| Place of Origin: | China |

| MOQ: | 1pcs |

| Price: | Negotiable |

| Payment Terms: | T/T,Western Union |

| Supply Ability: | 200pcs per month |

| Delivery Time: | 7-15 working days |

| Packaging Details: | wooden case or can be customized |

| Product Name: | PP Anticorrosion Electroplating Barrel For Electroplating And Barrel Plating |

| Application: | Electroplating barrel line machine equipment |

| Barrel Material: | PP |

| Applicable plating: | Plating for metal and plastic products |

| Size: | φ350×L452 |

| Motor: | 110V, 60HZ |

| Fittings: | Chemical Plating Tank |

| Company Info. |

| Surplus Industrial Technology Limited |

| Verified Supplier |

| View Contact Details |

| Product List |

PP Anticorrosion Electroplating Barrel For Electroplating And Barrel Plating

All of our machines use high quality imported material and most advanced equipment production technology.

We also have highly skilled and experienced workers,meanwhile,we have a sandardizd production process.

So we can provide customers with the most excellent and suitable service.

| Product Name | PP Anticorrosion Electroplating Barrel For Electroplating And Barrel Plating |

| Usage | Metal Surface Plating |

| Material | PP plate, Motor, and so on |

| Heating source | Electricity |

| Performance | High efficiency (> 90%) |

| Feature | Power Saving (over 30%) |

| Application | Galvanizing, Copper plating, Nickel plating, Gold plating |

| Size | φ350×L452 |

| Volume | According to your application performance |

| Warranty time | 1 years |

Packing & Shipping

In our company,various packing methods are adopted according to

different product features,such as carton boxes,wooden case etc.For

electroplating plant equipment ,we can discuss it together and

choose the most suitable one.

As for shipment,different ways have their own advantage and

disadvantage:

By sea: the cheapest,suitable for large amounts,but take more time

By Air: faster, more convenient, expensive

By Express: more flexiable, door to door, expensive

FAQ

1. How can I get an offer?

You can send your drawing with technology requirements and mark your purchase quantity of the product you need.It is much better if you could offer the usage information about products.

We will comfirm the most suitable material and quote our best price to you in 24 hours.

2. Can you accept OEM & ODM?

Yes,we can produce the products according to your demand and drawing.

3. What is your production lead-time for order?

Generally it takes 15-25 days for production.

4. What are your payment terms?

In generally,we quote EXW price+shipping cost,payment 50% deposit by T/T in advance,50% balance paid before shipment.

If the account is small ,so you can pay via Western Union.

Company Advantage:

1. Professional,Powerful, Precision Design

2. Build a quality levee to meet the challenges of the century

3. Focus on research and development for 18 years, master core

technology

4. Quality and Thoughtful Service

Related Product Show

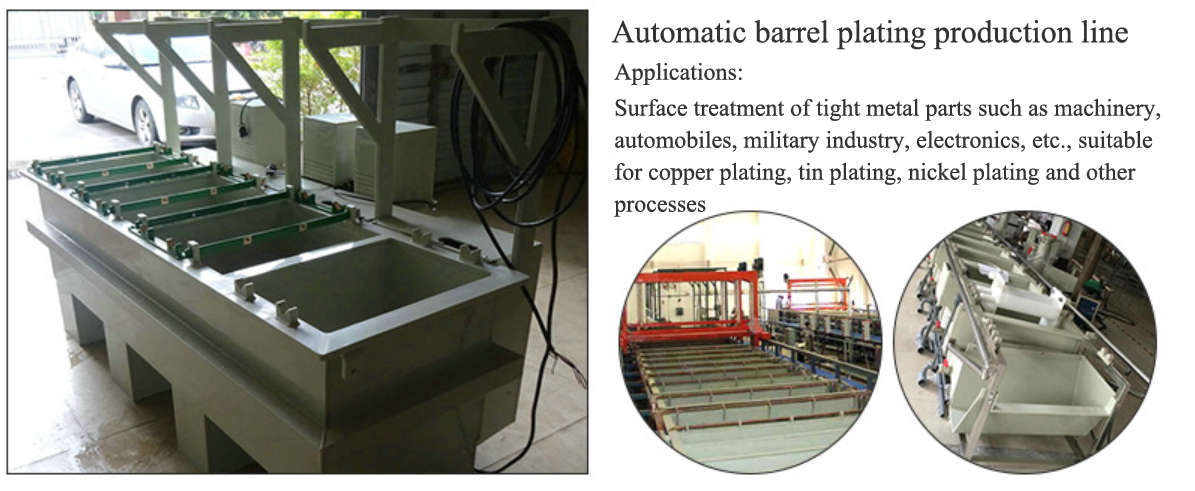

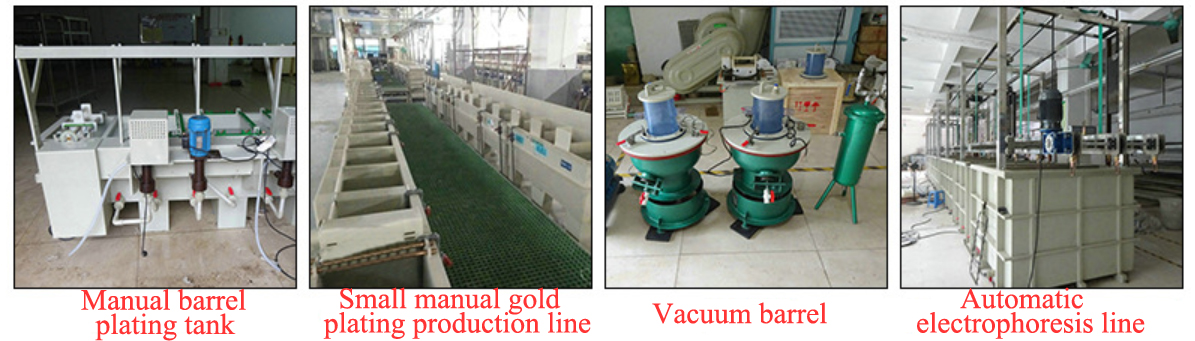

1. Automatic Barrel plating production line

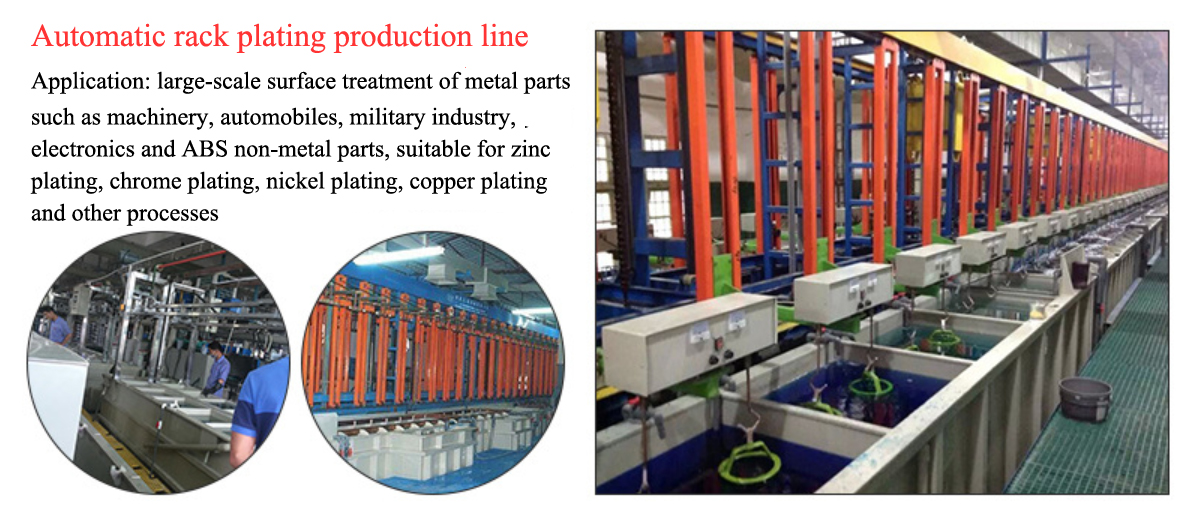

2. Automatic rack plating production line

Application: large-scale surface treatment of metal parts such as machinery, automobiles, military industry,electronics and ABS

non-metal parts, suitable for zinc plating, chrome plating, nickel plating, copper plating and other processes.

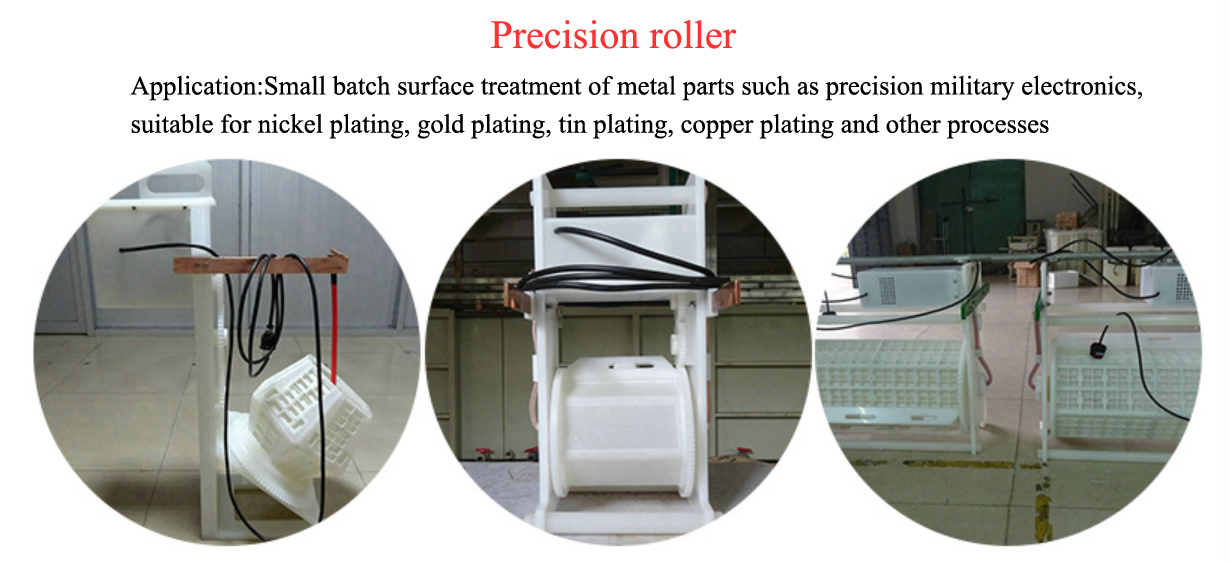

3. Precision roller

Application range:Small batch surface treatment of metal parts such as precision military electronics, suitable for nickel plating,

gold plating, tin plating, copper plating and other processes

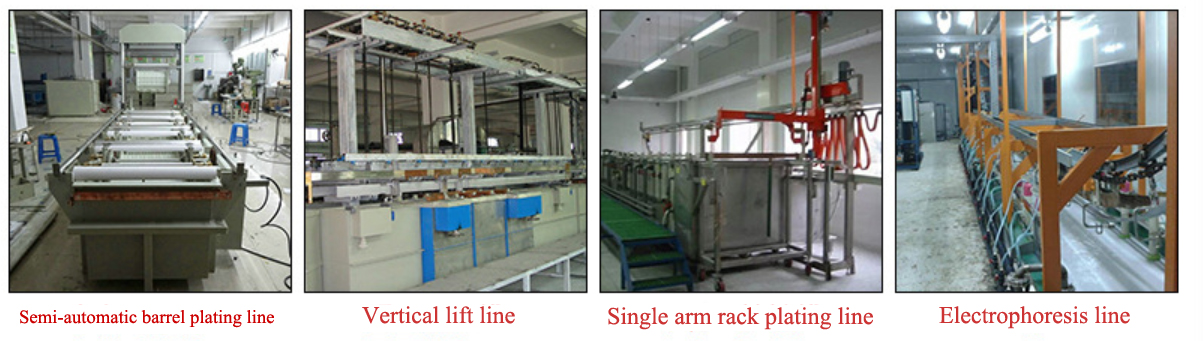

Related Project display

|

|

|

|

|