| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Tube Filling Machine |

|---|---|

| Brand Name: | XQ |

| Model Number: | XQJZ-2S-XYZ |

| Certification: | CE |

| Place of Origin: | China |

| MOQ: | 1 |

| Price: | USD 20000-25000/ SET |

| Payment Terms: | T/T |

| Supply Ability: | 20 SETS per Month |

| Delivery Time: | 20 Days |

| Packaging Details: | Wooden packing(75*93*100 cm) |

| Speed: | 12000 BPH(1.5ml) |

| Pump: | Ceramic pump(0.6-6ml) |

| Accuracy: | ±0.5% |

| Size: | 65*83*85cm |

| Weight: | 80 KGS |

| Mold: | Customized |

| Driven: | Full electric |

| Power: | 220V 50/60Hz 680w |

| Suitable Product: | Non-stand-well bottle |

| Material contact part: | Ceramic/SS 316L |

| Suitable Material: | Well-flowing liquid |

| Company Info. |

| Foshan Xiong Qi Intelligent Technology Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

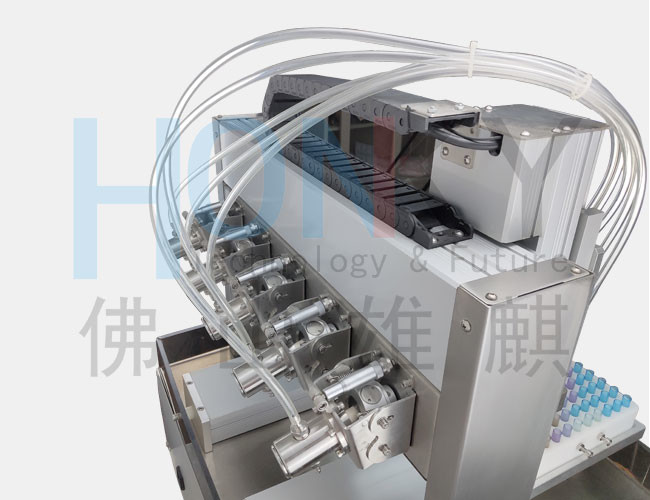

High Speed 12000 BPH 1.5ml Cosmetic Filling Machine Full Electric

12000 BPH Desktop High Speed Tube Filling Machine With Ceramic Pump

For Cosmetic Essential

Characteristic:

1. Automatic dual-channel bottle loading, multi-head filling.

2. Suitable for a variety of standing instability products.

3. The machine is made of stainless steel 304.

4. This equipment adopts XYZ three-axis linkage method, using

Japanese sensor, Taiwan rail, which makes the positioning precise.

5. The filling part adopts the precision ceramic pump developed

independently, and the repeated accuracy can reach ±0.3%.

6. The size of the machine can be customized according to the

customer’s need.

Technical parameters

| Target Products | Test tube/ampule/water needle/E-liquid bottle |

| Manufacturing speed | 130-140 PCS/min |

| Power | AC 220V 50-60Hz / 680w |

| product type | High Speed Filler |

1.Automatic dual-channel bottle loading, multi-head filling.

2.Suitable for a variety of standing instability products.

3.The machine is made of stainless steel 304.

4.The size of the machine can be customized according to the

customer’s need.

This equipment adopts XYZ three-axis linkage method, using Japanese

sensor, Taiwan rail, which makes the positioning precise.

The filling part adopts the precision ceramic pump developed

independently, and the repeated accuracy can reach ±0.3%.

|