| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Spray Drying Machine |

|---|---|

| Brand Name: | Xin ShengMan |

| Model Number: | LPG-5/10/100/200/300/500/1000 |

| Certification: | CE and ISO9001 |

| Place of Origin: | China |

| MOQ: | 1Set |

| Price: | USD10000-USD300000 |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 10sets/Month |

| Delivery Time: | 60-90days |

| Packaging Details: | Plywood cases |

| Warranty: | 1 year |

| Type: | Spray Dryer |

| Certificate: | ISO9001 and CE |

| Service: | engineers available to service machinery overseas |

| Heating Source: | electrical, oil, coal, steam |

| Power (Kw): | depend on the model |

| Steel Material: | stainless steel 304, carbon steel, or Q235A steel |

| Control: | PLC touch screen |

| Package: | Wooden case |

| Dimension (L*W*H): | depend on the model |

| Atomizer: | Centrifugal atomizer |

| Color: | Optional |

| Company Info. |

| Jiangsu Shengman Drying Equipment Engineering Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

LPG Model Low Temperature High Speed Centrifugal Spray Dryer Machine

Descriptions

The spray drier is widely used in the liquid shaping technology and

in the drying industry. Particularly it is suitable for producing

powder, granule or block solid product from solution, emulsion,

suspending liquid and pumped paste liquid.

Principle

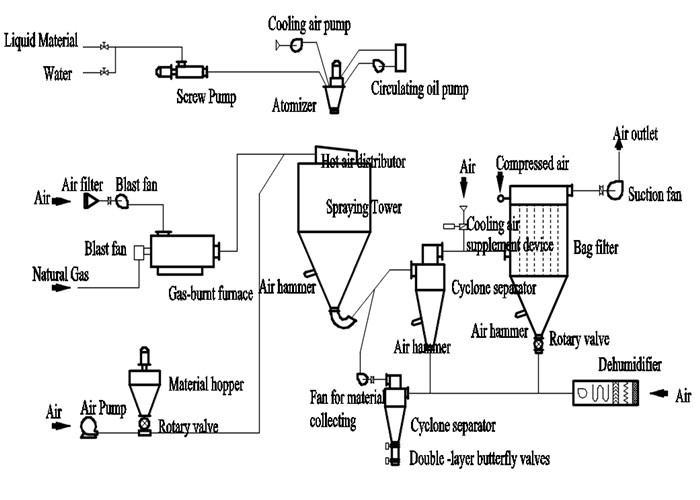

The working of spray dryer is as follows: Fresh air after filtering

and heating, enters into the air distributor at the top of the

dryer. Then the hot air enters into the drying chamber. The liquid

of raw material is pumped in through diaphragm pump, be atomized

into tiny droplets. Through the very short time of contacting the

hot air, the materials can be dried into the finished products. The

wasted air and fine powder will be collected through collector at

the bottom of the cyclone. The tower body also equipped with

observation door, sight glass, lamp-house and so on.

Features

1.LPG centrifugal spray dryer with fast drying speed can constantly

evaporate 95%-98% moisture. The drying time is about 5 seconds to

15 seconds. This drying equipment is especially suitable for

thermosensitive substance.

2.This spray dryer has excellent uniformity, liquidity and

solubility as well as high purity.

3.This spray drying machine has simple production process and easy

operation. After drying, it does not need to grind and screen,

which can reduce production procedure and enhance the purity.

Technical parameters

| Model | PLG | |||||

| 5 | 25 | 50 | 100 | 150 | 200-2000 | |

| inlet temperatyre ℃ | 140-350 automatically controlled | |||||

| outlet temperatyre ℃ | 80-90 | |||||

| Max water evaporation capacity kg/h | 5 | 25 | 50 | 100 | 150 | 200-2000 |

| centrifugal spraying nozzle transmission mode | compressed air transmission | mechaical transmission | ||||

| rotation speed (r.p.m) | 25000 | 18000 | 18000 | 18000 | 15000 | 8000-15000 |

| spraying desc diameter (mm) | 50 | 100 | 120 | 140 | 150 | 180-340 |

| max electric heating power (kw) | 9 | 36 | 63 | 81 | 99 | settled by customer |

| overall dimensions | 1.8*0.93*2.2 | 3*2.7*4.26 | 3.7*3.2*5.1 | 4.6*4.2*6 | 5.5*4.5*7 | depends on tryer |

| dried powder collection | ≥95 | ≥95 | ≥95 | ≥95 | ≥95 | ≥95 |

Applications

Chemical Industry: Sodium fluoride(potassium),alkaline dyestuff and

pigment, dyestuff intermediate, compound fertilizer, formic silicic

acid, catalyst, sulphuric acid agent, amino acid, white carbon and

so on.

Plastics and resin: AB,ABS emulsion,uric acid resin,phenolic

aldehyde resin,urea-formaldehyde resin,formaldehyde

resin,polythene,poly-chlotoprene and etc.

Food Industry: Fatty milk powder,protein,cocoa milk

powder,substitute milk powder,egg white(yolk),food and

plant,oats,chicken juice,coffee,instant dissoluble tea,seasoning

meat,protein,soybean,peanut protein,hydrolysate and so forth.

Sugar, corn syrup, corn starch, glucose, pectin, malt sugar, sorbic

acid potassium and etc.

Ceramic: aluminium oxide,ceramic tile material,magnesium

oxide,talcum and so on.

Company Information

Shengman is Drying Equipment manufacture. We are specialized in the

development, smanufacturing, and installation of dryers, mixers,

granulators, grinders, conveyors, sieve and etc.

We follow a strict quality control procedure and we provide

high-quality products with prompt after sales services and

technical support.

|