| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | PET Bottle Making Machine |

|---|---|

| Brand Name: | RiBo |

| Model Number: | BLMS-6H1.5L |

| Place of Origin: | Guangdong, China |

| MOQ: | 1 PC |

| Price: | Negotiable |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 60 PCS/Year |

| Delivery Time: | 90~120 days |

| Packaging Details: | Main machine and the preform feeding system will be packed by the wooden pallet,spare parts and the bottle blow mould will be packed by the wooden box. |

| Plastic Processed: | PET |

| Preform heating pitch: | 114mm |

| No.of Cav.: | 6 |

| Max.bottle volume: | 1500ml |

| Neck diameter range: | 18~38mm |

| Max.bottle diameter: | 96mm |

| Max.container height: | 320mm |

| Theoretical output: | 3600BPH |

| Rated power: | 98KW |

| Power consumption: | 60~70KW |

| Blow pressure: | 2.6~3.2Mpa |

| Air consuming: | 11m³/min |

| Warranty: | 12 months |

| After sales service: | Technicians can be sent to the site for installation and commissioning |

| Used for: | PET bottle making machine |

| Automatic: | Yes |

| Lead time: | 90~120 days |

| Blow moulding type: | Stretch Blow Moulding |

High Speed PET Hot Fill PET Bottle Making Machine / Automatic Blowing Machine For Water Bottle

Performance and Characteristics

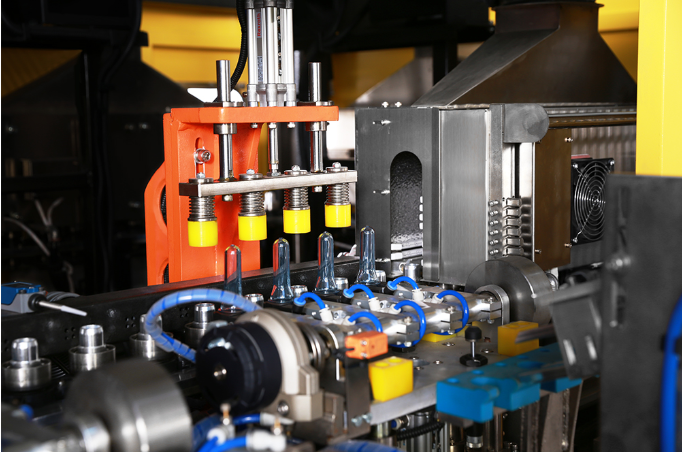

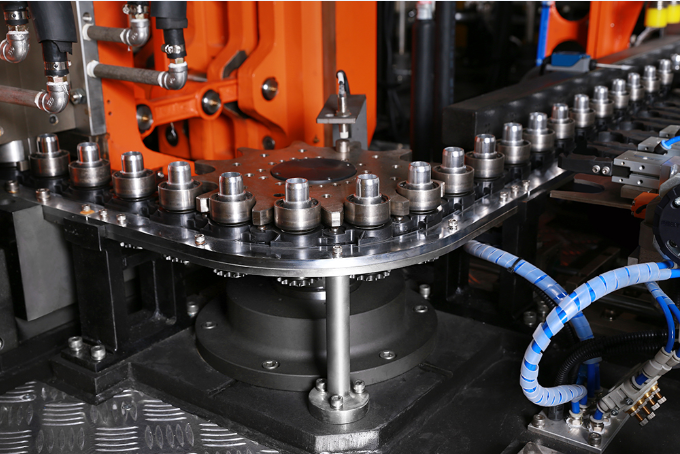

1. The servo motor is adopted to drive the molding mechanism, triggering off a bottom mold linkage as well. The whole

mechanism works speedy, accurately, stably and flexibly. Meanwhile, it is energy efficient and environmental safe.

2. The servo motor driven stepping system and stretching system have improved the speed, flexibility and accuracy of blowing.

3. The thermostatic heating system ensure that the heating temperature of each preform surface and internal is uniform. Hinged

oven holders make it easy for the operators to change infrared tubes and do maintenance.

4. The simple slide-in way of mold mounting makes it possible for the operators to change molds easily within 30 minutes.

5. The cooling system for the preform neck is equipped to ensure the preform neck does not deform during heating and

blowing.

6. The man-machine interface is highly automated and easy to operate. The compact machine occupies a smaller area.

7.Oil or electricity heated, the mold can ensure bottles meet the hot filling requirement and withstand a temperature up to 92℃

without deformation. The capacity of each cavity can be up to 700~850bph.

This series is used for PET hot filling bottle for juice, tea drinks ,energy drinks,milk drinks and other hot filling

drinks......ect

Technical Parameter

| Item | Unit | Moldel | |

| BLMS-6H1.5L | |||

| Molding Spec. | Preform Pitch | mm | 114 |

| Preform Heating Pitch | mm | 114 | |

| No.of Cav. | cav. | 6 | |

| Container Spec. | Max.Container Volume | L | 1.5 |

| Neck Diameter Range | mm | 18-38 | |

| Max.Containr Diameter | mm | 96 | |

| Max.Containr Height | mm | 320 | |

| ※※ Theoretical Output | BPH | 3600 | |

| Power Spec. | Rated Power | KW | 98 |

| Power Consumption | KW | 60~70 | |

| Compressor Spec. | Blowing Pressure | Mpa | 2.6~3.2 |

| Air Consuming | m³/min | 11 | |

| Mold Temp.Controller | Temperature | °C | 130-160 |

| Consumption | kcal/hr | 16200 | |

| Main Machine Spec. | Size | mm | 5050*2200*2500 |

| Weight | Kg | 8000 | |

| Note: Due to continuous technical development specification would be improved without prior notice. | |||

| Special designs correspond to customers needs. | |||

The parts of the bottle blowing machine

|