| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | V Cut PCB Depaneling Machine |

|---|---|

| Brand Name: | Winsmart |

| Model Number: | SMTD12 |

| Certification: | CE |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | USD1-10000/set |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 200 sets per month |

| Delivery Time: | 2-5 days |

| Packaging Details: | Plywood case |

| Color: | White |

| Weight: | 600kgs |

| Dimension: | 1500x800x1500mm |

| Min Panel: | 122x12mm |

| Max Panel: | 300x300mm |

| Name: | V Cut PCB Depaneling |

| Company Info. |

| Winsmart Electronic Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

V Cut PCB Depaneling Machine PCB Depaneler Improved Productity

V Cut PCB Depaneling Machine Features:

1. A single group of multiple cutters can be divided automatically, and different cutters can be made according to different products.

2. Equipped with acrylic cover to ensure safety.

3. The electrical control part can be selected in the man-machine interface, convenient to open or shield.

4. There is a dust collecting tray under the knife mold.

5. Adopt square welding frame, sheet metal sealing plate, steel paint baking on the surface.

6. Suitable for all V-groove panels.

7. Depaneling material: FR, aluminum

V Cut PCB Depaneling Machine Process:

Step 1: The upper board mechanism sends the PCBA to the predetermined track, the transport track sends the PCBA to the top of the lower straight knife, the lower straight knife rises, the upper straight knife moves and cuts in the Y direction until all V scoring lines in the Y direction are cut.

Step 2: The separated boards cut by the Y direction flows to multiple groups of multiple cutters through the track, and the PCB cut in the X direction is finished at one time.

Step 3: The single separated PCB falls on the discharge conveyor belt and flows into the back work station.

Step 4: There is a vacuum cleaner under the cutter die of the machine to absorb the dust.

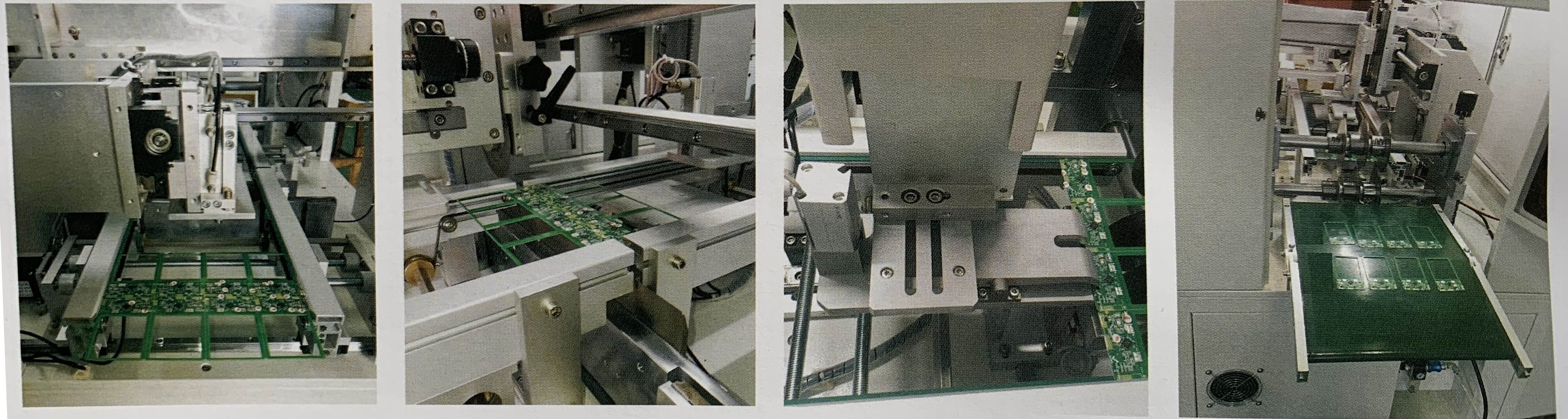

V Cut PCB Depaneling Machine Details:

V Cut PCB Depaneling Machine Specification:

| Machine Dimension | Name | Inline V-Cut PCB Depaneling |

| Dimension | 1500*800*1500mm | |

| Weight | 600kgs | |

| Color | White | |

| Usage Requirements | Power Supply | AC220V, 1800W |

| Air Supply | 0.6MPa | |

| Environment | Clean and dry, avoid humidity or high temperature | |

| Min distance between component and scoring line | 1.5mm | |

| PCB Panel Range | 12x12mm – 300x300mm | |

| Feeding door adjustment | Fixed front side, adjutable back side | |

| Max component height | Upper 35mm, bottom 20mm | |

| Software | PLC | Local brand |

| Parameter setting | Setting on touch screen | |

| Storage | Available for 50 programs | |

| Touch screen | Taiwan brand | |

| Sensor | Omron | |

| Blade Spec | Material | Japan high steel |

| Angel | 10-30 degree | |

| Life time | 3,000,000 times | |

| Knife mold precision | 0.1mm | |

| Replace knife mold time | 60 minutes | |

| Other Function | Wrong operation protection | Sensor, software |

| Safe protection | Emergency stop switch | |

| Power and gas cut off function | Yes | |

| Self check function | Start up time monitoring, capacity monitoring, equipment fault information and automatic exclusion system |

V Cut PCB Depaneling Machine Shipping Ways:

|