| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Air Filter Making Machine |

|---|---|

| Brand Name: | PLM |

| Model Number: | PU-20F |

| Certification: | CE |

| Place of Origin: | CHINA |

| MOQ: | 1SET |

| Price: | USD 23000/SET |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 5 SETS PER 30DAYS |

| Delivery Time: | 20 DAYS AFTER DEPOSTI |

| Packaging Details: | EXPORT STANDARD WOOD CARTON |

| PRODUCT NAME: | Automatic Filter Gasket Pouring Machine Air Filter Making Machine |

| Overalloutput: | 5~15g/s |

| Design mixture ratio: | A:B=100: 25~35 |

| Speed of travel: | 2-10m/min |

| Overall power: | 8kw |

| Maximum size on circular automatic lading: | Φ350mm |

| Maximum size on quadric automatic ladling: | 400×300(L×W) |

| Automatic shift extent on the pouring nozzle after operation: | 450mm |

Automatic Filter Gasket Pouring Machine Air Filter Making Machine

Automatic Filter Gasket Pouring Machine Air Filter Making Machine Applications

It is mainly used for the pouring of automobile air filter and industrial filter PU.

Automatic Filter Gasket Pouring Machine Air Filter Making Machine Consists

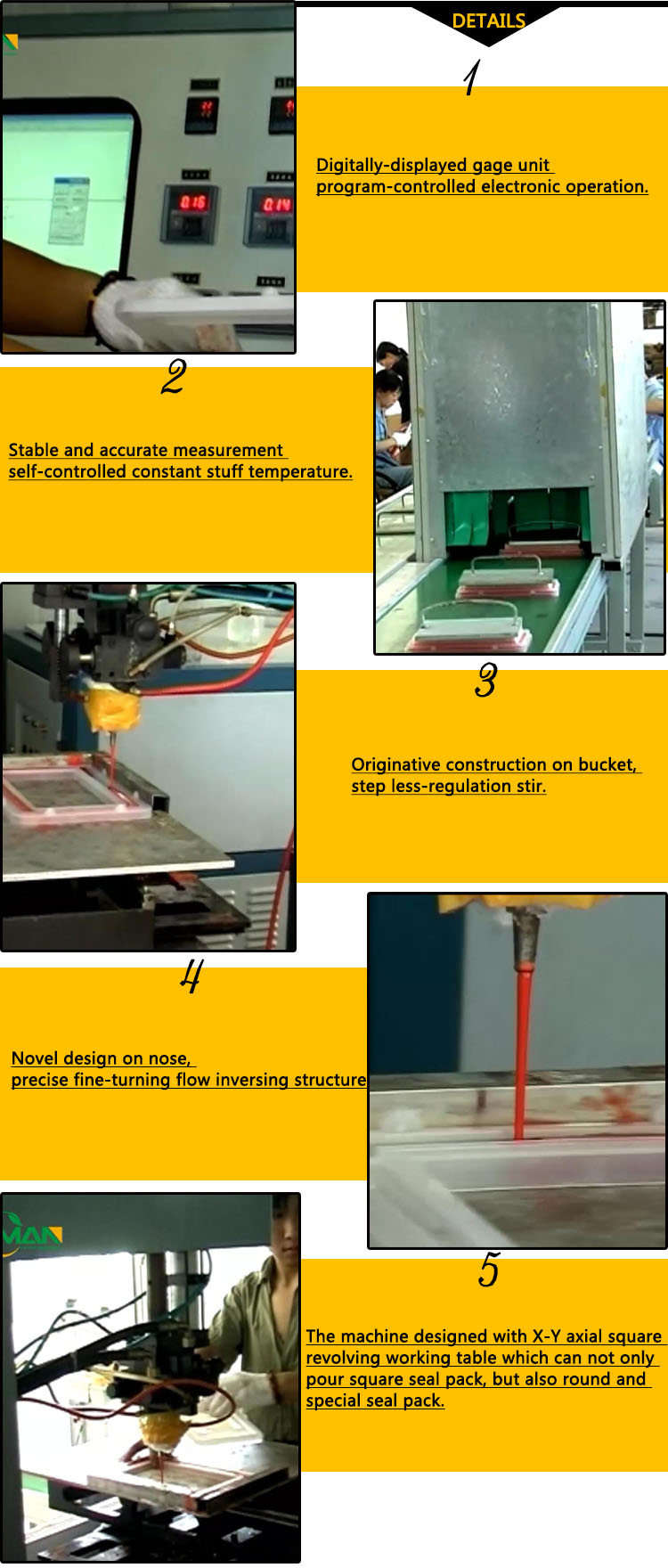

1 Digitally-displayed gage unit program-controlled electronic

operation.

2 Stable and accurate measurement self-controlled constant stuff

temperature.

3 Originative construction on bucket, step less-regulation stir.

4 Novel design on nose, precise fine-turning flow inversing

structure.

5 The machine designed with X-Y axial square revolving working

table which can not only pour square seal pack, but also round and

special seal pack.

Automatic Filter Gasket Pouring Machine Air Filter Making Machine Specification

| Overall output | 5~15g/sdesignmixtureratio:A:B=100:25~35 |

| Automaticshiftextentonthepouringnozzleafteroperation | 450mm |

| Maximum size on quadric automatic ladling | 400×300(L×W) |

| Maximum size on circular automatic lading | Φ350mm |

| Speed of travel | 2-10m/min |

| Overall power | 8kw |

| Power supply | 380V/50Hz |

| M/C weight | 1000kg |

| M/C size | 1500×2000×2100mm(L×W×H) |

Automatic Filter Gasket Pouring Machine Air Filter Making Machine photo

Machine characteristics

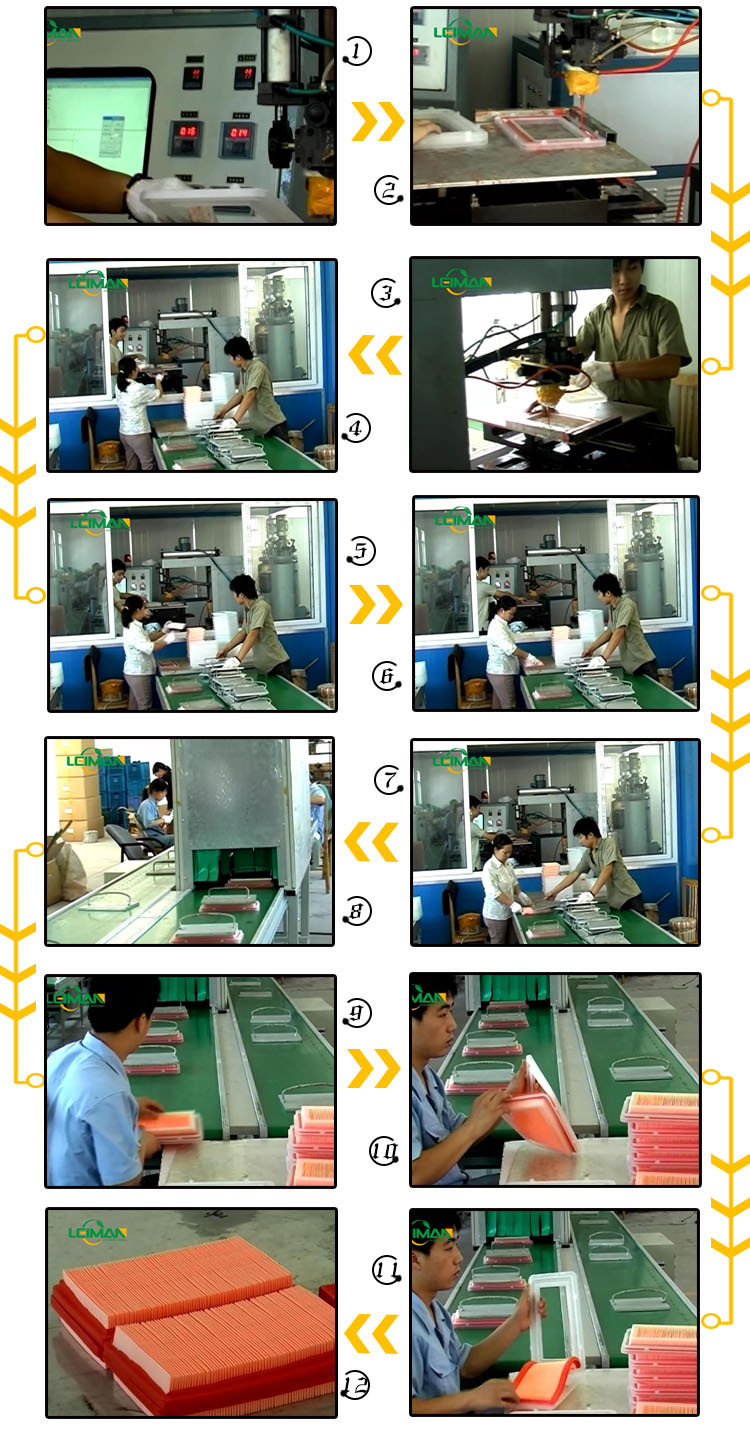

Operating procedures

|