| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Alumina Ceramic Parts |

|---|---|

| Brand Name: | China |

| Model Number: | 008 |

| Place of Origin: | Suzhou,China |

| MOQ: | 100pcs |

| Price: | Negotiable |

| Payment Terms: | T/T |

| Supply Ability: | 10000 Piece/Pieces per Month |

| Delivery Time: | 25 days |

| Packaging Details: | Box, Carton, Wooden, Bag etc. Customized package |

| Product name: | High Hardness Low Density Alumina Ceramic Plate |

| Material: | Alumina Ceramic |

| Application: | Industrial Ceramic |

| Length: | 3mm ~ 2000mm |

| Water Absorption: | 0% |

| Electrical Insulation: | excellent |

| Density: | 3.9g/cm3 |

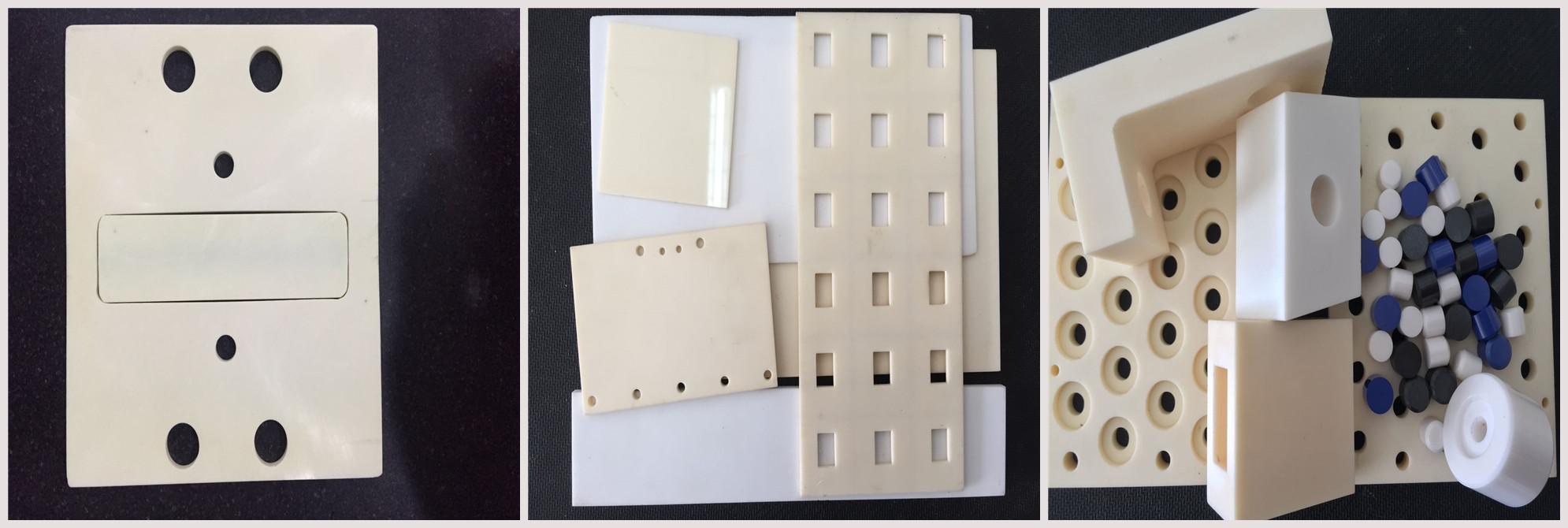

High Hardness Low Density Alumina Ceramic Plate

Description:

The alumina plate is made of aluminum oxide ceramics. Alumina is a ceramic material with high thermal conductivity, compressive strength, and thermal shock resistance. It also has a low thermal expansion, making it a suitable material for furnace use in the crucible, tube, and thermocouple sheath form. Aluminum oxide ceramic plates can withstand high temperature and maintain high strength and hardness.

Technical Parameters:

| Test item/Unit | Numerical Value | Test item/Unit | Numerical | ||||

| Product Material | Alumina | Zirconia | Product Material | Alumina | Zirconia | ||

| Component Content % | ≥99% | ≥95% | ≥90% | Volume Resistance MM | >1012 | >1012 | >1012 |

| Sintering Temp ℃ | 1780-1800 | 1650-1680 | 1550-2600 | Bending Strength Mpa | 400 | 320 | 1100 |

| Specific Gravity g/cm3 | ≥3.8 | ≥3.6 | >6 | Thermal Expansion Coefficient'10' | 6.8-8.0 | 6.2-8.5 | 6.9-10 |

| Breakdown Voltage Strength kv/mm | 15 | 15 | 15 | Roughness um | ≤0.8 | ≤0.8 | ≤0.8 |

| Bibulous Rate% | <0.01 | <0.01 | <0.01 | Mirror Polished Ra | ≤0.05 | ≤0.1 | ≤0.05 |

| Anti Pressure Mpa | 3700Mpa | 2400Mpa | 5000Mpa | Thermal Conductivity W/m.k | 25 | 20 | 25 |

| Hardness Hra | ≥88 | ≥82 | ≥88 | Temperature Resistance ℃ | 1700 | 1600 | 1800 |

Advantages:

1.High thermal conductivity of more than 170W/m. K.

2.High resistivity.

3.Low dielectric loss.

4.Good insulation.

5.Some other excellent properties.

Application:

1.Ceramics, mines and other grinding equipment lining.

2·Material thansfer equipment.

3·inside and outside surface of powder separating equipment on iron and steel works.

4·Thermal and power plants.

More pictures:

|