| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Alu Alu Blister Packing Machine |

|---|---|

| Brand Name: | Rich Packing |

| Model Number: | DPP-260r |

| Certification: | CE/ISO 9001/SGS |

| Place of Origin: | Guangzhou, China |

| MOQ: | 1 pcs |

| Payment Terms: | L/C, D/P, T/T, Western Union |

| Supply Ability: | 50 pcs/month |

| Delivery Time: | 5-8 working days |

| Packaging Details: | Standard export wood case the machine is first wrapped with a transparent film, and then bound in a wooden box to ensure the safety of the machine during transportation. |

| Production capacity: | 1.8~236,000 grains/hour |

| Number of blanking: | 20~180 boards/min |

| Maximum forming area: | 160×250*15mm |

| Maximum depth: | 26mm (customized) |

| Standard Travel Range: | 40-160mm |

| Standard plate: | 80*57mm |

| PVC thickness/width: | 260×0.15~0.45mm |

| PTP aluminum foil thickness/width: | 260×0.02~0.03mm |

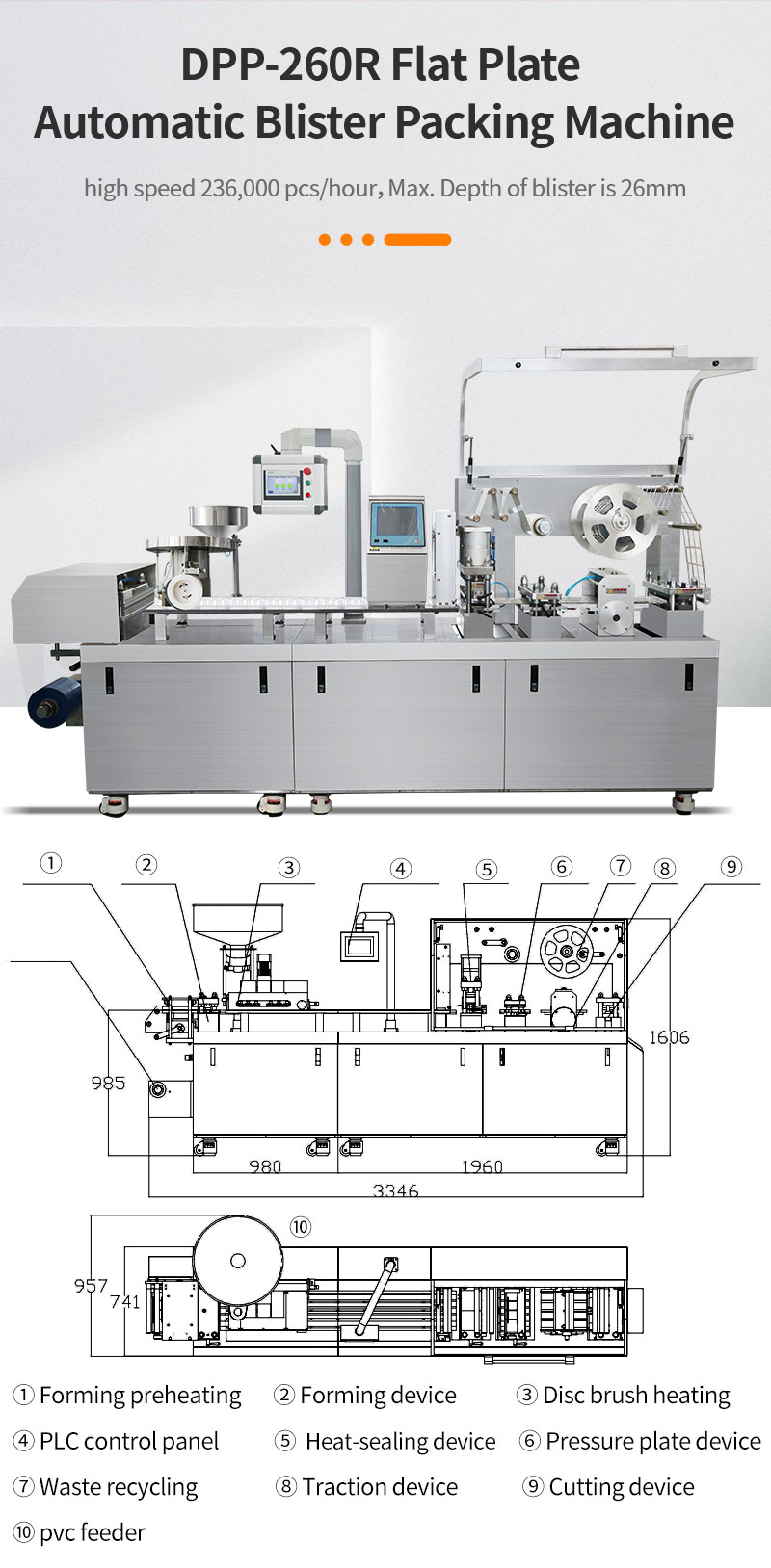

DPP260r Alu Alu Blister Packing Pharmaceutical Alu Plastic Blister Machine

Following the pace of scientific life, our professionals have realized new technology on 260r alu plastic packing machine. The 260r alu plastic packing machine has a well-known configuration and excellent functions, making it a general-purpose machine for production in all walks of life.

The 260r alu plastic packing machine has won praises from many customers in terms of quality and is famous for its convenient operation of the machine. Why is 260r alu plastic packing machine easy to operate? Because you only need to prepare materials, you can work on the machine at other times. This kind of production process can save manpower and staff costs, and can also improve the production efficiency of products, which is suitable for large and medium-sized production industries.

At present, people are increasingly using aluminum plastic machines, the most commonly used of course are medicines and cosmetics. And now the technology is advanced, and the demand for machine production is increasing.

| Model | alu plastic packing machine |

| The production capacity | 1.8~236,000 grains/ hour |

| The maximum molding area and depth | 160 × 250 * 15.1mm |

| Maximum depth | 26 mm (can custom) |

| The main motor power | 1.5 KW |

| The total power(kw) | 6.0 kw |

|