| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Wheelset Press |

|---|---|

| Brand Name: | Heqiang Machinery |

| Model Number: | HQ01-AF400 |

| Certification: | ISO9001 |

| Place of Origin: | China |

| MOQ: | One set |

| Price: | Negotiable |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 20 sets per year |

| Delivery Time: | 180 days after advance payment & design finalization |

| Packaging Details: | Standard export packing |

| Application: | Railway depots and rolling stock enterprises |

| Usage: | Mount and dismount railway wheelsets |

| Pressing force: | 400t |

| Ram cylinder: | Double cylinders |

| Support trolley: | One set |

| Operation mode: | Fully Automatic |

| Oil injection system: | 1set for oiling pressing |

| After-sales service: | Engineer available to service machiney oversea |

| Company Info. |

| Hubei Heqiang Machinery Development Limited by Share Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

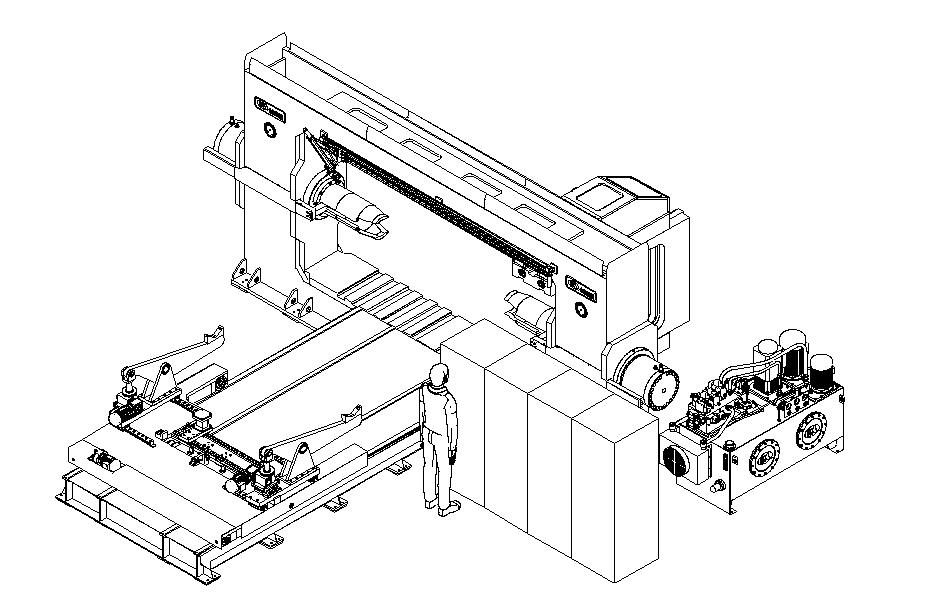

400t Locomotive Automatic Wheel Press With Double Cylinders With Oil Injection System

Hubei Heqiang Machinery is the leading manufacturer of wheel set press machines in China. It offers the most advanced wheel set pressing equipment available in the railway and other relevant industry. The wheelset presses are used to mount and dismount all of the elements on the axle (wheel discs, brake discs, gears and bearings). With both single and double cylinder version available for option and capacity range from 200 to 800 tons. Our vast range of machines can satisfy all customer requirements in both maintenance and mass production applications.

Application scope:

This Automatic Wheel Press Machine is mainly used for the mounting (colding pressing and oiling pressing), dismounting and back pressure testing of locomotive wheelset wheel discs and driven gears of the HXD series locomotive wheelsets. It can generate, record, save and print the pressing curve (Pressure vs displacement, pressure vs time). A rotation device is supplied with the machine to perform wheel back-to-back, axial run-out and radial run-out measurements after the mounting process has been completed.

Technical parameters:

| Pressing force | 400t |

| Ram cylinder | Double head cylinders |

| Maximum ram stroke | 900mm |

| Ram approach speed | 0~20 mm/s, adjustable |

| Ram pressing speed | 0~4 mm/s, adjustable |

| Return speed | 0~24 mm/s, adjustable |

| Max load of the centring devices | 10000 kg |

| Wheelset support trolley | 1 set, Electrical type |

| Max trolley load | 8000 kg |

Hydraulic system pressure | Maximum 31.5 MPa |

| Noise level during working | Not more than 75 dB |

| Main power supply | 3 phase, AC, 380V/50HZ |

| Total installed power | Not more than 30 kW |

| Pressure sensor accuracy | Not more than 0.1% FS |

| Inner distance control accuracy | Not more than ±0.2 mm |

| Wheel position difference control accuracy | Not more than 0.2 mm |

| Ram positioning accuracy | Not more than ±0.01 mm |

| Ram re-positioning accuracy | Not more than 0.025 mm |

| Resolution of measuring elements | Not more than 0.01 mm |

| Pressing cycle time | Not more than 12 minutes per axle |

| Maximum Wheelset weight | 8000 kg |

| Axle length | 2200 ~ 2500 mm |

| Wheel diameter | Φ700 ~ Φ1350 mm |

(*Above parameters are indicative, and can be modified as per customer's requirements.)

Machine features:

Cooperation contact:

If you are interested in our wheel presses or any assistance required, please feel free to contact with me by email or Whatsapp,Wechat, Skype. We'll give you feedback in the first time.

|