| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Lost Wax Precision Casting |

|---|---|

| Brand Name: | SJNB |

| Model Number: | SJ7292217 |

| Certification: | TUV;PED |

| Place of Origin: | China |

| MOQ: | 1000 |

| Price: | Negotiation |

| Payment Terms: | T/T |

| Supply Ability: | 30,000-50,000 pcs per month |

| Delivery Time: | 30 days |

| Packaging Details: | Wood BOX |

| Part Name: | Machinery and equipment investment castings |

| Application: | Industrial Machinery and equipment |

| Standards available: | Carbon steel 1.4308 |

| Production process: | investment casting,precision casting, machining |

| type: | Carbon steel precision casting |

| Size: | customized |

Lost Wax Casting Castings Investment Casting Foundry ISO 9001

Product parameter

| Product name | Carbon steel Lost Wax Investment Casting |

| Application | Construction hardware Auto parts and accessories Boat parts and Marine hardware |

| Standards available | Carbon steel |

| Production process | investment casting,precision casting, machining etc. |

| Size | customized by your requirement . |

| Acceptable drawing formats | DWG,DXF,IGES,STEP,PDF |

| MOQ | 1000 PCS |

| Packing | Standard export plywood case . |

| Delivery time | 30 days normally. |

| Payment | T/T, L/C,D/P,Paypal. |

| Port | Ningbo, China |

| Certifications | ISO9001;2008,TS16949:2016 |

| Main Market | America, Australia, European ,Japanese , Middle east etc. |

| Production capacity | 10,000,000 pcs/year |

Ningbo Suijin havs lost wax investment casting technology for a variety of materials,Stainless steel casting, Alloy steel casting,Carbon steel casting,Bronze and Brass casting, Aluminum casting. We can supply OEM service(custom service) in precision investment casting,which are also called lost wax casting, We have been committed to this technique from 2003 . Our precision investment casting Heat treatment procedures include Annealing,Solution,Normalizing,Tempering,Quenching,Induction hardening and Hardening and tempering.Our precision investment casting machining procedures include Drilling, Reaming and tapping,CNC,Turning machining,CNC Milling machining and Wire EDM.Our precision investment casting Surface treatment procedures include Manual polishing,Electro-polishing,Electro-plating,Power coating,Tumbling.Our specialized engineer can provide you the full-service of technology advice and products improving projection,and also reduce the cost of the parts.

If you need us to submit a quotation,

1. Please provide drawing or sample, The format of the drawing can be PDF, IGS, DWG, STEP, etc.

2.Together with relevant information, such as quantity, weight, material, material grade, tolerance, machining demands, surface treatment, heat treatment, mechanical property requirements, etc.

3. Our specialized engineer will check and quote for you, we would appreciate the opportunity and will respond in 3-5 working days or less.

4. If you do not have a drawing, we can duplicate your sample and make drawing for your confirmation.

lost wax precision castings Packing

Technique: Precision casting, Investment casting, Lost wax casting, Stainless steel precision casting

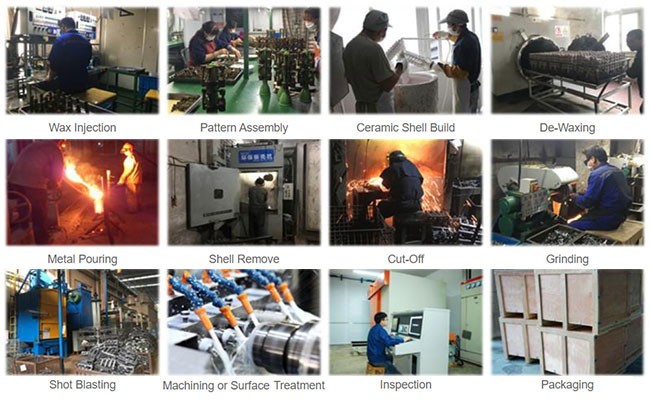

Lost wax castings parts Process flow chart

Wax Injection→Make Wax pattern and repair→Inspection→Shell Making→De-waxing→Roasting Shell and Melting Steel→Composition Inspection→Pouring→De shelling→Cutting and Grinding the pouring gate→Inspection→Heat treatment→Shotblasting→Machining→Anti-Corrosion→Final Inspection→Shipping

Our company and factory

We manufactured all kinds of lost wax investment castings and machining parts or called precision investment castings , material including carbon steel, alloy steel, and stainless steel. we also can according to the customers' requirement to compound the material, Our factory has a floor space of 33,000 square meters and another 18000 square meters of building area, which contain both casting foundries and CNC machining area. Our advanced lost wax casting and investment casting production lines have a capacity of 5000 tons lost wax castings and 1000 tons investment castings per year.

|