| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | 5 Gallon Water Bottling Machine |

|---|---|

| Brand Name: | BOTTLING MACHINERY |

| Model Number: | QGF-1500 |

| Certification: | CE/ISO9001-2008 |

| Place of Origin: | Zhangjiagang city Jiangsu provice China |

| MOQ: | 1 |

| Price: | 20,000-100,000USD |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 1sets per month |

| Delivery Time: | 20-25 working days |

| Packaging Details: | Sea shipping Wooden case |

| Application: | 5 gallon Bottle water filling |

| Capavity: | 1500 bottles per hour(for 18.9L bottle) |

| Filling heads: | 14pcs |

| Automatic De-capper: | 1200*500*2100 mm 180kg |

| Linear type external washer: | 3500*1200*2100mm 1000kg |

| Monoblock jar rinser: | 13000*2300*2500mm 5500kg |

| Automatic rotary jar filler: | 3000*2300*2200mm 3000kg |

| Automatic cap lifter-washer: | 800*800*3000mm 130kg |

Description of 1500BPH Stainless Steel 3 / 5 gallon water bottling machine

Linear type external washer:

The machine is controlled by PLC and used for gallon jar outside

brush washing; When the jars are sent into the machine by the

conveyor, the brushes inside driven by motor will rotate quickly.

The main brush shape is made according to jar shape and size which

the jar neck and shoulder will be washed completely. Water showing

will be done at the same time of brush washing.

No air compressor needed, it is easy for production and

maintenance;

Parameters:

Dimension: 3500*1200*2100mm

Weight: 1000kg

Power: 3 KW

Main brush :20pc

Bottom brush :10pcs

Water tank:1pc

With the protect barrel function

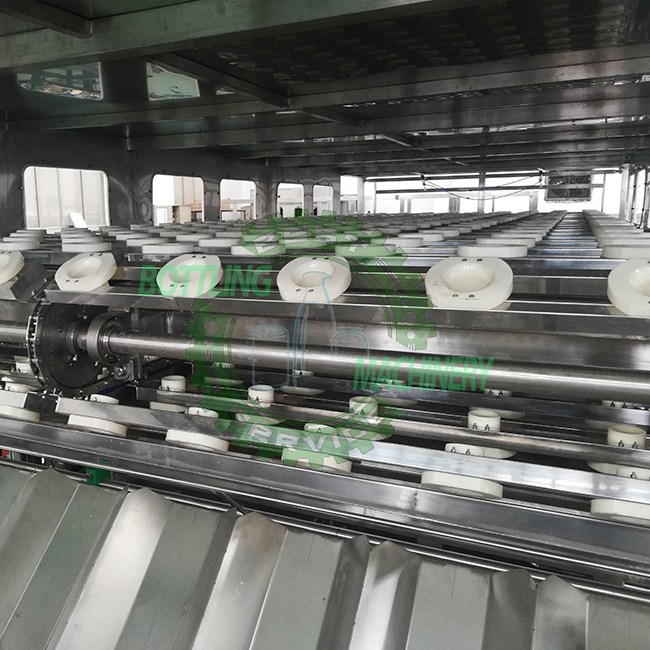

Monoblock jar rinser(with up-down type rinsing heads)

When the power is turned on, PLC was electric start work, the

flushing and chain conveyor electrical work, then automatic bottle

makes the bottle gradually into each process starts flushing

(flushing time and lye temperature can be adjusted via the touch

screen), flushing is completed, bottle after bottle rack down to

fall on the conveyor.

The machine has four tanks: 2pcs hot alkaline water tank(different

target temperature), 1pc of disinfect water tank, 1pc back water

tank. a funnel with a Plexiglas cover, you can inside the water

level monitoring.

Tank has a low level alarm, when too much water, it can overflow

through the overflow port; alkali tanks are equipped with

thermostatically controlled heater.Each tank has a bottom drainage,

mix water is discharged through the outlet via the drainage duct.

Pure water is not equipped with a water tank, direct access to

NanFang water pumps.Each pump outlet has a valve, flush the water

off automatically guarantee pass; does not work when the outlet

water from the valve to return to their tank (finished water back

to the pump before the pipeline), to avoid the pump frequent

starting, improved life of the pump.

Bottle unloading mechanism consists of propping bucket, bottle rack

stand, vertical cylinders and other components, bottle washing is

completed, after falling off the bottle, directly on the conveyor.

Parameters:

Plate thickness: 2mm SUS 304

Water pump: NanFang

Motor: SANLI

Cylinder: AIRTAC

Photo sensor: Autonics

Air consumption: 0.6M3/min; 0.6Mpa

Heating Power: 18KW, other parts Power: 6KW

Dimension: 13000*2300*2500mm

Weight: 5500kg

Automatic rotary jar filler

Parameters:

Power: 5KW

Filling heads: 14pcs

Dimension: 3000*2300*2200mm

Weight: 3000kg

Automatic Arm rotary type stacker

It adopts slide-type self-gravity roller conveyor to transfer the

barrel, no power consumption in standby;

The automatic palletizer can stack five gallons of finished water

into 3 layers, each with 16 barrels, that is, 16*3=48 barrels, and

the speed can reach -2000 barrels/H, which not only saves the area

of finished water, but also greatly saves Number of labor and labor

intensity of workers;

This product has the advantages of perfect performance, simple

operation, stable and reliable work, reasonable structure,

convenient maintenance, and high degree of automation. It meets the

requirements of food hygiene and is the most ideal product for

5-gallon barrel drinking water manufacturers.

Equipment list of 1500BPH 5 gallon bottle packing line:

| Items | Name of machine | Model | Size(mm) | Qty. | |

| 1500BPH 5 gallon water packing line | |||||

| 1.1 | Automatic De-capper | BG-3 | 1200*500*2100 | 1set | |

| 1.2 | Linear type external washer | LXT-10 | 3500*1200*2100 | 1set | |

| 1.3 | Monoblock jar rinser | CXJ-24 | 13000*2300*2500 | 1set | |

| 1.3.1 | Automatic jar loading-unloading device | ST-6 | / | 1set | |

| 1.4 | Automatic rotary jar filler and capper | TG-14 | 3000*2300*2200 | 1set | |

| 1.4.1 | Automatic cap lifter-washer | SG-1 | 800*800*3000 | 1set | |

| 1.5 | Sleeve labeling machine | TB-50 | 1500*800*2000 | 1set | |

| 1.5.1 | Steam shrink tunnel | / | 600*600*1000 | 1set | |

| 1.5.2 | Connection conveyor system and motor for shrink labeling system part | 6m | |||

| 1.6 | Checking Light | CL-1 | 1000*100*450 | 1pc | |

| 1.7 | Conveyor Belt(254mm)*14meters+corner belt conveyor*1pcs+ Motor (0.75KW)*2sets+roller conveyor*4meters+corner roller conveyor*1pcs | 1suit | |||

| 1.8 | Ink jet code printer | OH-338 | 347*220*100 | 1set | |

| 1.9 | Automatic Arm rotary type stacker | RMD-2000 | 2500*1850*2600 | 1set | |

Monoblock jar rinser:

|