| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Carbide Punch Pin |

|---|---|

| Brand Name: | PM |

| MOQ: | 1 |

| Payment Terms: | L/C, T/T |

| Delivery Time: | 10 working days |

| Product material: | tungsten carbide,100% Original Carbide |

| Product: | Mold Parts |

| Grade: | MD40A |

| Application: | For Upper and Lower dies,Stamping and Cutting |

| Type: | Any Type |

| Advantage: | Electrochemical corrosion resistance;Hip sintered, high hardness, high wear resistance;Tunable residual stress; |

| Surface treatment: | Polishing |

| Usage: | For mould, Stamping Work, Cemented carbide dies, |

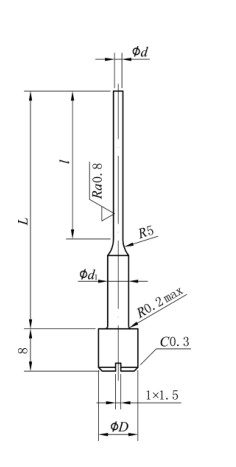

Stacking Ejector Pins TYPE B

High performance cemented carbides for molding;Standard Specification For Square Material and Standard Specifications Of The Rings. Also we can produce the your drawing of ring.

Polarization curve (corrosion current reduced, corrosion rate decreased significantly, corrosion resistance improved significantly)

Our advantages

1. High quality

2. Reasonable price

3. On time delivery

4. Good After-sale service

5. Strict quality control

| Grade | Co% | WC Grain size | Hardness | Density | Flexural Strength | Fracture Toughness | Elastic Modulus | Coefficient of Thermal Expansion | |

| HRA | HV30 | g/cm3 | MPa | N/mm2 | GPa | 10-6/℃ | |||

| MD40B | 12 | Fine | 89.5 | 1380 | 14.2 | 3800 | 17 | 470 | 5.7 |

| MD40C | 12 | Fine | 89.7 | 1400 | 14.1 | 3800 | 16 | 470 | 5.7 |

| MD40A | 12 | Medium | 88.9 | 1310 | 14.2 | 3700 | 27 | 470 | 5.7 |

| MD45A | 15 | Medium | 87.9 | 1200 | 13.9 | 3600 | - | 430 | 6.3 |

| TYPE D | |||||

| d ±0.002 | D±0.002 | D1±0.05 | L+0.5 +0.3 | l1 | l2 ±0.02 |

| 1.0 | 5.5 | 3.5 | 55,60 | 18,20 | 18,20 |

| 1.2 | 5.5 | 3.5 | 55,60 | 18,20 | 18,20 |

| 1.5 | 5.5 | 3.5 | 55,60 | 18,20 | 18,20 |

| 1.8 | 6.0 | 4.0 | 55,60 | 18,20 | 18,20 |

| 2.0 | 6.0 | 4.0 | 55,60 | 18,20 | 18,20 |

|