| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Aluminum Strip |

|---|---|

| Brand Name: | Yongsheng |

| Model Number: | ALuminum strip |

| Certification: | SGS |

| Place of Origin: | Henan China |

| MOQ: | 1 tons |

| Price: | USD2500tons |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, |

| Supply Ability: | 5000tonspermonth |

| Delivery Time: | 20workdays |

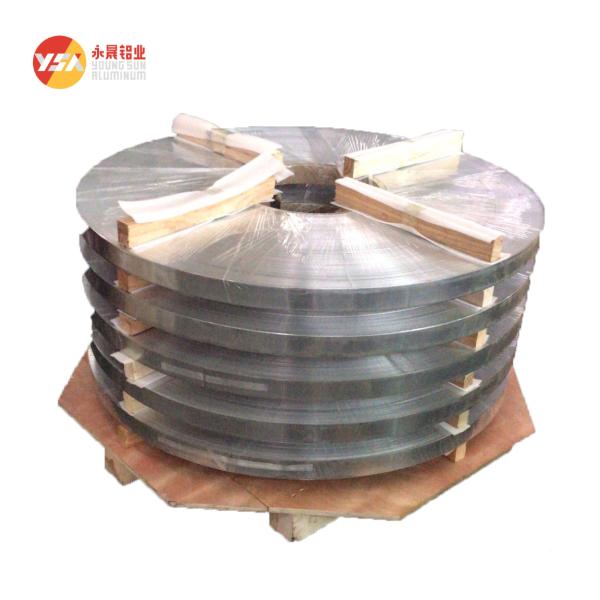

| Packaging Details: | wooden package |

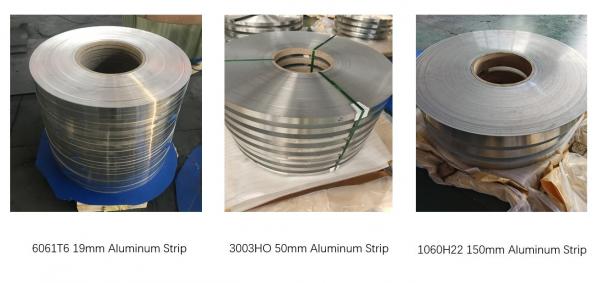

| alloy: | 1000series-8000series |

| temper: | O-H112,T3-T8 |

| thickness: | 0.13mm-6.5mm |

| width: | 3mm-2600mm |

| length: | as your requirements |

| application: | industry、decoration、building、packing、pressing |

| Company Info. |

| Henan Yongsheng Aluminum Industry Co.,Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Product Name : 1060 3003 5052 6061 Thin Aluminum Coil Strip 1mm 2mm

20mm

Aluminum Strip Description

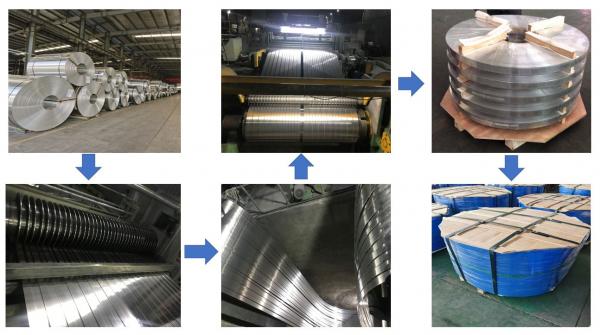

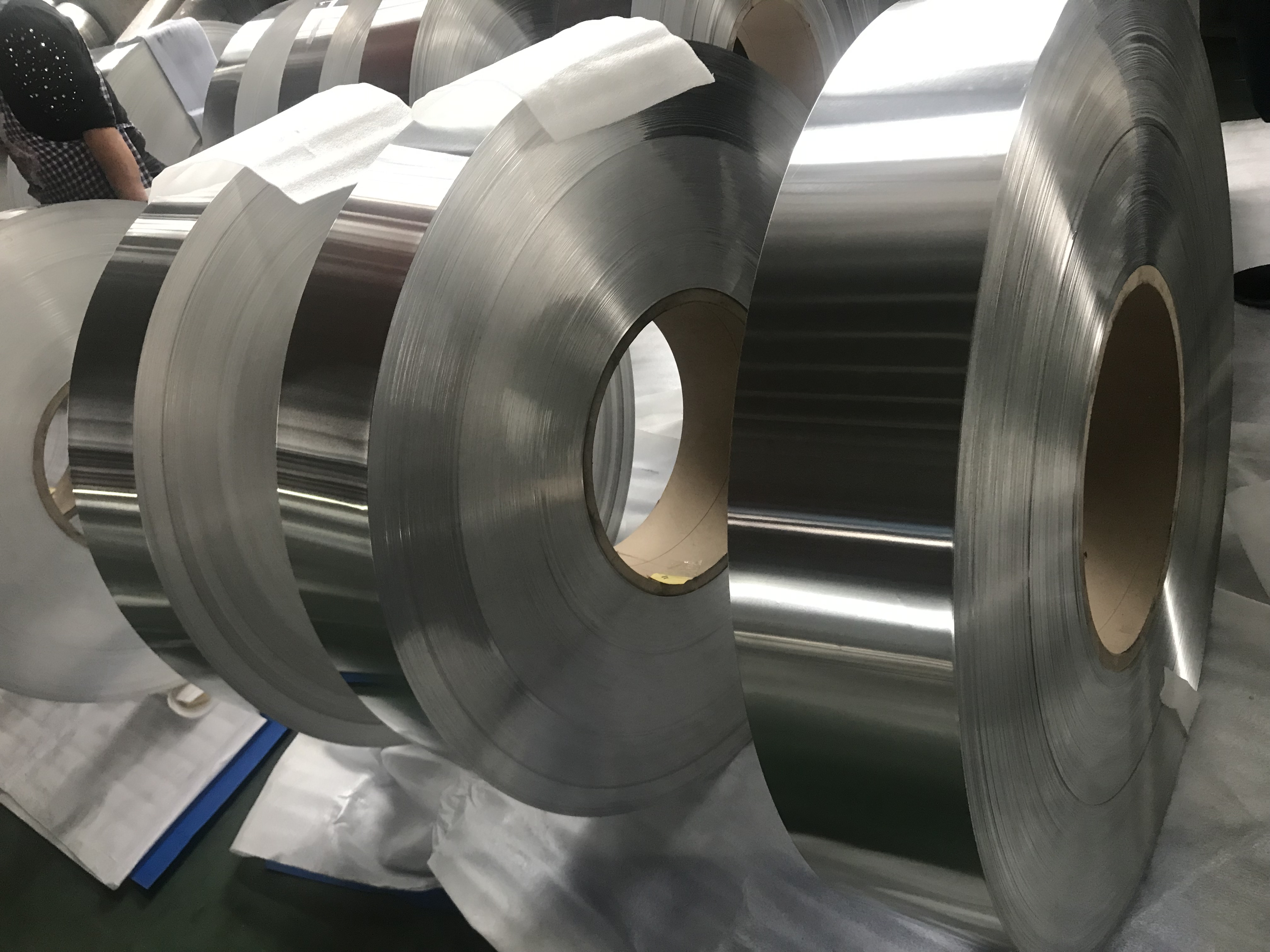

The raw material of the aluminum strip is pure aluminum or aluminum

alloy cast rolled aluminum coil , hot rolled aluminum coil , by the

cold rolling machine rolling into different thickness , width of

the sheet aluminum coil , and then according to the use , by the

slitting machine longitudinal cutting into different width of the

aluminum strip . Our equipment is more advanced in the industry ,

our engineers have many years of practical experience , and have

professional operation skills . The raw materials are produced and

processed by our factory , and the technical standards , chemical

composition and physical properties can be precisely controlled .

The aluminum strip produced by our company has the advantages of

high precision and stable product quality , and has been well

received by customers for many years .

Aluminum Strip Technical Data

Aluminum Strip Use

Aluminum Alloy Belt Categories :

| Alloy | State | Thickness(mm) | Tensile Strength | The Yield Strength(Mpa) | elongation | hardness |

| 1060 (1050) | 0 | >0.2-0.5 | 60-100 | ≥15 | ≥20 | 20-30 |

| >0.5-1.0 | ≥30 | |||||

| >1.0-4.0 | ≥35 | |||||

| H22 | >0.2-0.5 | 80-120 | ≥60 | ≥12 | 30-40 | |

| >0.5-1.0 | ≥15 | |||||

| >1.0-4.0 | ≥18 | |||||

| H24 | >0.2-0.5 | 95-135 | ≥70 | ≥6 | 35-45 | |

| >0.5-1.0 | ≥8 | |||||

| >1.0-4.0 | ≥10 | |||||

| H26 | >0.2-0.5 | 110-155 | ≥75 | ≥2 | 43-55 | |

| >0.5-1.0 | ≥4 | |||||

| >1.0-4.0 | ≥6 | |||||

| H18 | >0.2-0.5 | ≥125 | ≥85 | ≥2 | 50-65 | |

| >0.5-1.0 | ≥3 | |||||

| >1.0-4.0 | ≥4 | |||||

| 1100 (1200) | 0 | >0.2-0.5 | 75-105 | ≥25 | ≥18 | 25-30 |

| >0.5-1.0 | ≥30 | |||||

| >1.0-4.0 | ≥35 | |||||

| H22 | >0.2-0.5 | 95-130 | ≥75 | ≥12 | 30-40 | |

| >0.5-1.0 | ≥15 | |||||

| >1.0-4.0 | ≥18 | |||||

| H24 | >0.2-0.5 | 110-145 | ≥95 | ≥6 | 38-40 | |

| >0.5-1.0 | ≥8 | |||||

| >1.0-4.0 | ≥10 | |||||

| H26 | >0.2-0.5 | 130-165 | ≥115 | ≥2 | 45-60 | |

| >0.5-1.0 | ≥4 | |||||

| >1.0-4.0 | ≥6 | |||||

| H18 | >0.2-0.5 | ≥150 | ≥130 | ≥2 | 55-70 | |

| >0.5-1.0 | ≥3 | |||||

| >1.0-4.0 | ≥4 |

|