| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Dust Collector Filter Bags |

|---|---|

| Brand Name: | AUSTIN FILTER |

| Model Number: | F80-1 |

| Certification: | ISO9001-2008 |

| Place of Origin: | MADE IN CHINA |

| MOQ: | 100 pcs |

| Price: | Negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union |

| Supply Ability: | 1000 pcs per day |

| Delivery Time: | 3 days |

| Packaging Details: | Pallet , Carton box,knitting bags |

| Material: | 100% super fine Fiberglass |

| Scrim: | 100% PTFE scrim |

| Bag size: | DN 130x 6000 mm |

| Work temp.: | 260 degree |

| Air permeability: | 15-30 m3/m2.m |

| Application: | all kinds dust collector |

| Name: | High temperature resistance filter bag |

| Filtration efficiency: | < 20mg/Nm3 |

| Life: | 36 months |

| Treatment: | PTFE dipping and coating |

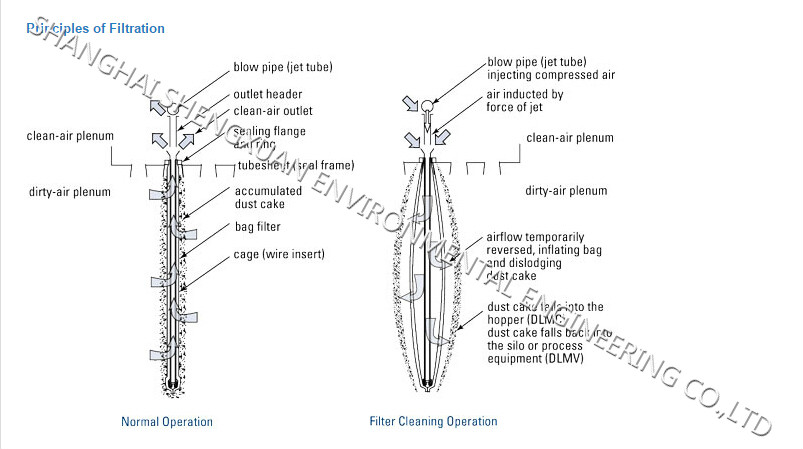

The pulse-jet or reverse-pulse baghouse is ubiquitous in industrial dust collection. These industry workhorses boast no moving parts in their basic configurations and allow collection efficiencies greater than 99.9%. In the pulse jet dust collector, the dusty airstream usually enters from below the bags or filters and is pulled upwards through the filters where dust is captured on the exterior surface and clean gas passes through to the clean air plenum side for exhaust. When fabric filters are used, the bags are supported by internal wire cages. The pulse-jet cleaning cycle is controlled by a solid-state timer which sequentially pilots “pulses” of compressed air in the reverse direction of filtering, into blow pipes mounted above each row of filters. When activated, the reverse pulse air pulses travel down the length of each bag in the given row, causing a ripple effect, dislodging and releasing the caked dust into the hopper at the base. A main advantage of the pulse jet baghouse is that it does not have to be taken off-line to clean the filters. With the dust removal programmed for regular or on-demand intervals, the system offers more complete cleaning and reconditioning of the filter bags than the other systems. Operating costs are minimal outside of the cost for compressed air for cleaning.

There are a few commonly used industrial dust collector filter bag medias used with industrial dust collectors. Polyester, Aramid, Fiberglass, P84, and PTFE are all common options that are available at different price points and have varying characteristics such as maximum operating temperature, resistance to chemicals and acids, ability to withstand abrasion and more.

| Article name | Weight | Thickness | Air permeability | Working temp. |

| Polyester | 450-700gsm | 1.6-2.2mm | 8-18 m3/m2.m | 130 degree |

| Polypropylene | 400-600gsm | 1.8-2.2mm | 8-20 m3/m2.m | 80 degree |

| Acrylic | 450-600gsm | 1.6-2.2mm | 8-20m3/m2.m | 125 degree |

How to choose the filter bag ?

The filter bag plays a key role in the dust-cleaning process, so it is very important to do the filter selection, which should be based on its performance and the nature of the smoke, so as to have a rational and optimized scheme.

The Factors that affecting the selection of the filter medium

The Select Indication of the Filter medium

A. Temperature

B. Chemical Property

C. Concentration of the dust content

D. Filter Gas Speed

Test Item & Test Standard

| SL.No. | Item | Test Standard |

| 1 | Area Weight | FZ/T60003-91 |

| 2 | Air Permeability | GB/T5453-1997 |

| 3 | Tensile Strength | GB/T3923.1-2013 |

| 4 | Elongation | GB/T3923.1-2013 |

| 5 | Burst | GB/7742.1-2005 |

| 6 | Liquid Repellent | GB/4745-2012 |

Post Treatment For Filtering Materials

Singeing, calendaring,Heat setting

Water and oil repellent

PTFE Dispersion treatment

PTFE surface Coating treatment

Fire Retardant treatment

Package detail and Delivery time

Samples delivery time : 1 ~ 2 days

Normal products : Available stock

LCL orders delivery time : 7~10 days

FCL orders delivery time : 15~20 days

Shipping way & Loading Port :

By sea / air / express

Shanghai / Ning Bo/Tianjin

|