| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Aluminum Spare Parts |

|---|---|

| Brand Name: | Trumony |

| Certification: | IATF16949 |

| Place of Origin: | China |

| MOQ: | 500kg |

| Price: | Negotiation |

| Delivery Time: | 25days |

| Packaging Details: | Fumigated pallet specialized for export |

| Production process: | Extrusion,CNC machining,Milling,Welding,Punching,Cutting |

| Fin height: | 95mm;140mm |

| Bottom plate thickness: | 16mm |

| Fin space: | 2-5mm |

| Processing accuracy: | Linear tolerances +/-0.01mm within 130mm |

| Application: | Electric vehicles,Power Electronics,Solar, Wind power, IT, Medical |

| Company Info. |

| Trumony Aluminum Limited |

| View Contact Details |

| Product List |

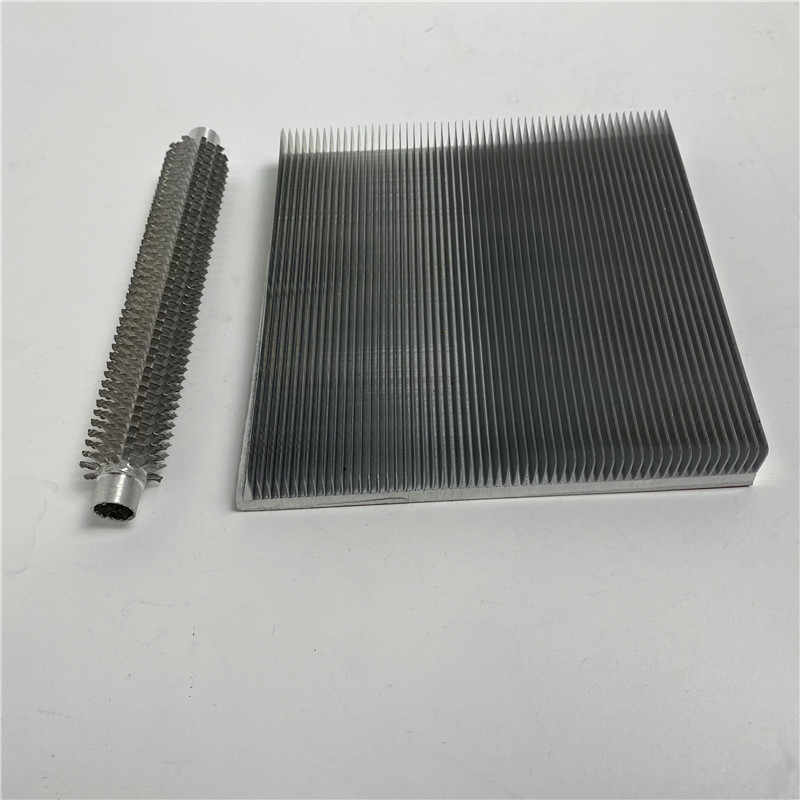

Aluminum-Copper Composite Heatsink Aluminum Spare Parts For High Power Inverters

Products introduction:

Our traditional heatsink are including Aluminum heatsink,Metal

stamping parts,Copper heatsink.Besides,we are also having new

heatsink,including Riveted Insert Fin Heatsink,Extrusion Skiving

Heatsink,Friction Welding Heatsink,Copper Aluminum Embedded

Heatsink

Co-Al welding heatsink,Heat pipe heatsink,Module Heatsink.

We are supplying the heatsink and hardware solution for following

industrial:

1) Communication Electronic (LCD, ADSL)

2) Power Electronic (UPS, Variable Frequency)

3) Green Energy (Wind & Solar)

4) Electric Automobile

Our production equipment list:

1) Fully automatic teething machine

2) Friction mixing welding machine

3) Automatic cutting machine

4) CNC processing center

5) High-precision pneumatic punch

6) Ultrasonic cleaning machine and a large number of professional processing machines

Our testing equipment list:

1) Common test capability is used to monitor out-going quality

2) CMM

3) Water cooled plate PressureTester

4) Thermal performance test equipment

Product specifications:

| Item | Description |

| Product name | Aluminum spare parts |

| Aluminum extrusion parts | |

| Heatsink | |

| Aluminum stamping parts | |

| CNC machining parts | |

| Manufacturing process | Extrusion |

| Stamping | |

| Punching | |

| CNC machining | |

| Welding | |

| Milling | |

| Bending | |

| Wire-cutting | |

| Production machines | automatic teething machine |

| friction mixing welding machine | |

| automatic cutting machine | |

| CNC processing center | |

| high-precision pneumatic punch | |

| ultrasonic cleaning machine |

Our advantage

1. Keep up with the changes of market environment (new energy, 5G

market and other new industries' demand for heat dissipation);

2. It has innovative advantages and a professional thermal

evaluation and R & D team.

3. The entry of management mode such as continuous improvement.

Brief MFG process:

Extrusion-Saw cutting-Stamping-Drill/Tap-Riveting-Assembly/Packing/Shipping-CNC Machning

|