| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Injection Molding Medical Parts |

|---|---|

| Brand Name: | Bokda |

| Model Number: | BKD0032 |

| Certification: | ISO, ZTC |

| Place of Origin: | Sichuan---The hometown of Panda |

| MOQ: | 100 pieces |

| Price: | Negotiable |

| Payment Terms: | T/T, Western Union, MoneyGram, Alipay, Credit card etc. |

| Supply Ability: | It's up to the detailed products |

| Delivery Time: | Determined by the quantity |

| Packaging Details: | Plastic bags, carton and wooden box |

| Molding type: | Injection molding |

| Material: | ABS, PVC, PEEK etc. |

| Product name: | Plastics parts injection molding medical parts |

| Color: | Natural and customized |

| Size: | According to the equipment |

| Application: | Medical equipments |

| ODM: | Acceptable |

| Surface finish: | Texture, printing etc. |

| Design software: | Solidworks, UG etc. |

| Process: | Precision mold process |

Medical Grade Injection Molding Medical Parts Plastics Precision Components

Product parameters

Company introduction:

Bokda owns two manufacturing plants, and the area of new plant over 14,000 square meters. Among them, the steel structure workshop area is more than 6,600 square meters.

At Bokda, our custom industrial molding solutions assist clients in a variety of industries, including military industry, medical, food processing, mining, oil and gas, waste-water management, electronic appliances, health care & beauty etc.

Our comprehensive services:

1.Product design

We can develop new products based on your ideas, sketch, samples or

prototypes.

2.Mold analysis

This is a very important process,because we need to understand the

possibility of production in advance so as to avoid some potential

problems , such as air trap, trace, shrinkage... To save cost,

control quality and guarantee production time.

3.Prototyping

Many clients are not sure whether the products they develop can accurately match the equipment, so many times they need to use 3D molding technology before making molds.

4.Injection mold

We can make the injection mold with different requests, and our mold life can reach at least 300000 shots.

5.Injection molding

We have more than 35 sets of injection machines, from dozens of tons to thousands of tons.

6. Mold storage

We'd like to store clients' molds for future production, and we have saved more than a thousand sets of molds for previous clients. If the mold exceeds its service life, we provide free mold repair service to save cilents' time and cost.

Key words: ABS plastic molding, prototype tooling, custom plastic injection molding

Products Show:

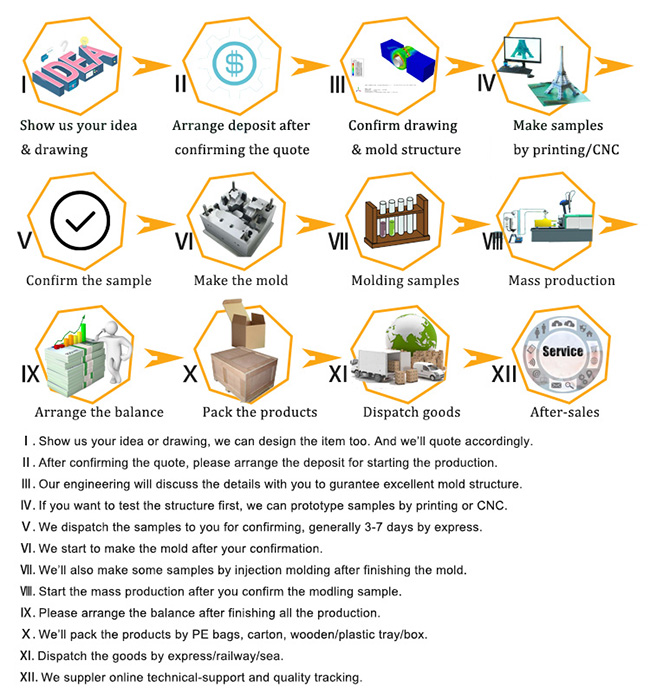

Business process:

|