| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Injection Molding Mold |

|---|---|

| Brand Name: | Bokda |

| Model Number: | BKD00088 |

| Certification: | ISO9001 |

| Place of Origin: | Sichuan---The hometown of Panda |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | T/T, Western Union, MoneyGram, Alipay, Credit card etc. |

| Supply Ability: | 20 sets per month |

| Delivery Time: | Based on the detailed item and quantity |

| Packaging Details: | Plastic bubble and wooden box. |

| Product name: | Customized injection mold |

| Surface treatment: | High gloss polishing, texture etc. |

| Cavity: | Single or multi |

| Runner: | Hot runner or cold runner |

| Shaping mode: | Injection molding |

| Application: | Medical parts, auto parts, elctronic fiitings, instrument componnets etc. |

| Gate type: | Side gate |

| Design software: | UG, CAD |

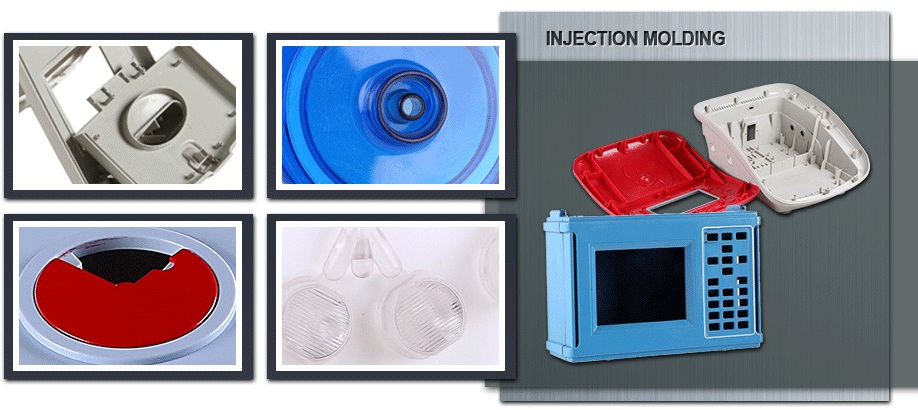

Custom Types Of Injection Molding Mold For Electronics Connectors Auto Parts

Molds (mú jù) are various molds and tools used in industrial production to obtain desired products by injection molding, blow molding, extrusion, die-casting or forging molding, smelting, and stamping. In short, a mold is a tool used to make molded objects. This tool is composed of various parts, and different molds are composed of different parts.

Product Parameters:

Product Description | Precision injection molding mould for kinds of plastics |

Plastic Materials | PS, ABS, PP, PVC etc. |

Certificate: | ISO9001:2005 |

Other materials: | Rubber, Slilconce rubber, LSR,Aluminum, Zinc,Copper...Metal...etc. |

Quality: | RoSH and SGS standard |

Feature: | Non marking and Non flash |

Size: | According to your 2D, 3D Drawing |

Color,Quantity,Unit price,Tooling cost,Tooling size: | Negotiable |

Package: | Standard exported Wooden box |

Mold Building Lead Time: | T1, 4-5 weeks, Part measurement report (upon required). |

Prducts Show:

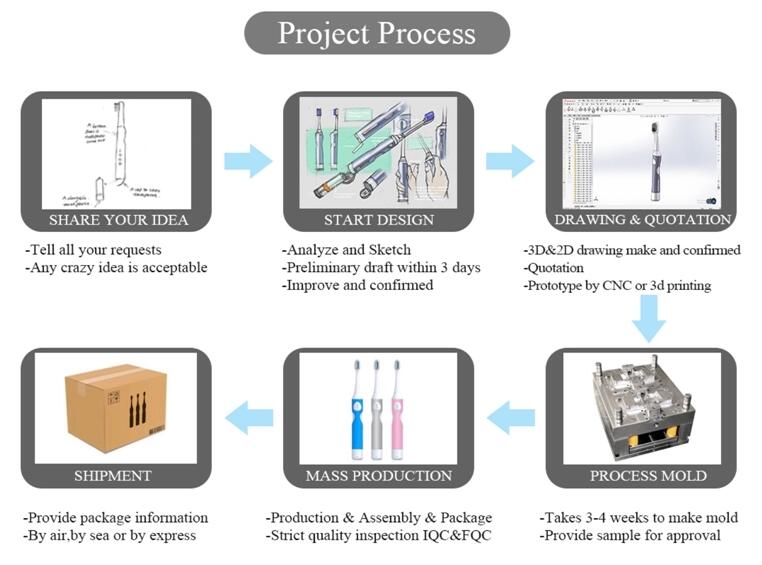

Project process:

Company information:

Since its establishment, the company has been committed to the

technology accumulation and research and development of the mold

industry. It has experienced R & D, design team and senior

technical personnel, equipped with advanced high-precision CNC

processing, production, testing and other equipment, with a

complete and scientific quality management system and mature

production technology.

|