| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Plastic Granulating Line |

|---|---|

| Brand Name: | LIANDA |

| Certification: | CE,ISO9001 |

| Place of Origin: | CHINA |

| MOQ: | 1set |

| Payment Terms: | T/T, L/C |

| Delivery Time: | 5~8weeks |

| Supply Ability: | 100 sets/year |

| Voltage: | Customized |

| Applied: | PE,PP film |

| Warranty period: | 12 months |

| Service: | 24 hours |

| Company Info. |

| LIANDA Machinery Co.,Ltd. |

| View Contact Details |

| Product List |

Film compacting granulating machine line,PP Jumbo bag granulating machine, PP/PE Film Recycling machine

| No | Machine Name | Quatity (set) |

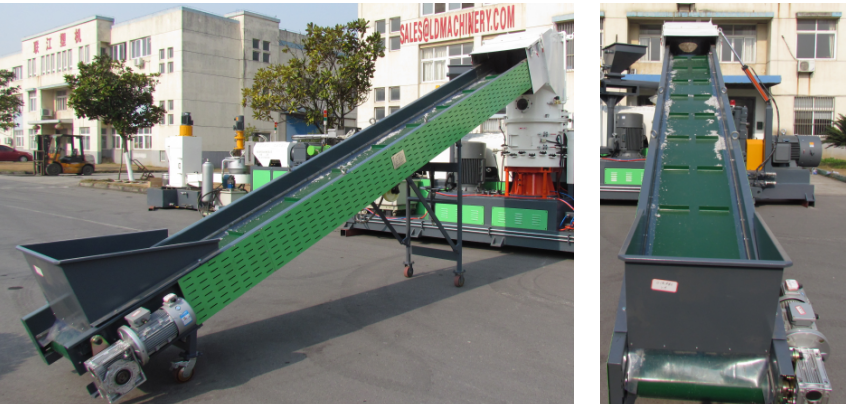

| 1 | Belt conveyor | 1 |

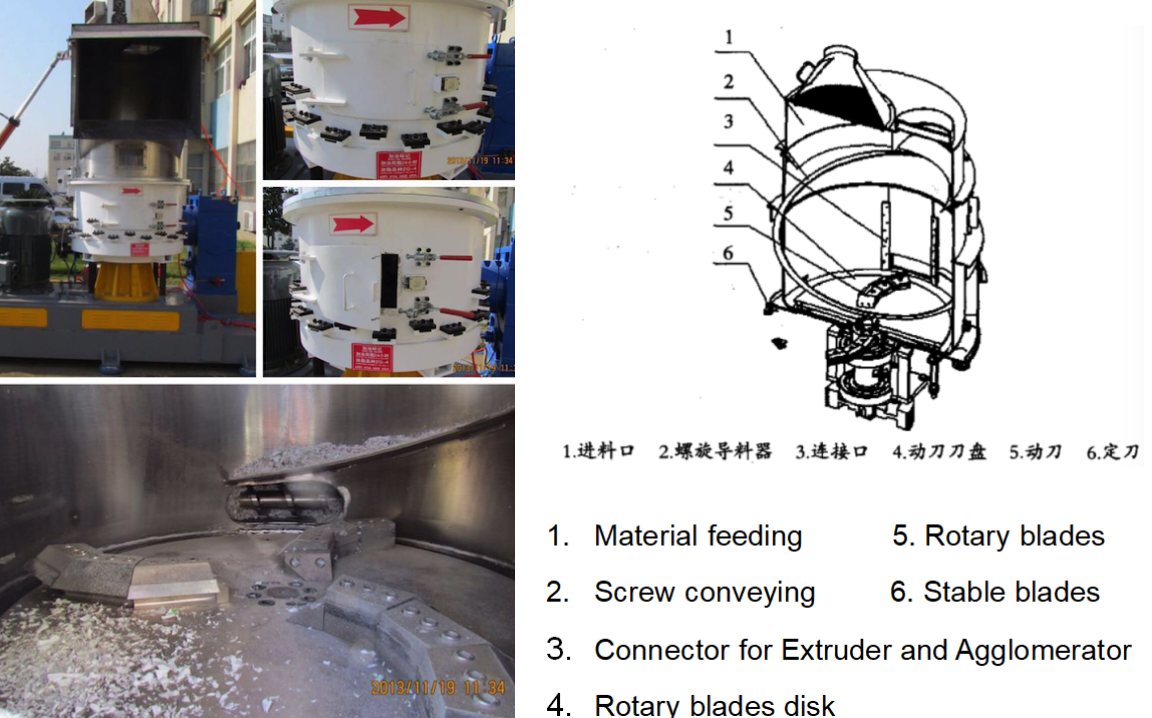

| 2 | Film compactor/Agglomerator | 1 |

| 3 | Single Screw Extruder (Single or Double step ) | 1 |

| 4 | Vacuum degassing system | 1 |

| 5 | Hydraulic screen changer filteration system | 1 |

| 6 | Water-ring pelletizing system | 1 |

| 7 | Dewatering machine | 1 |

| 8 | Vibrating sieve | 1 |

| 9 | Air conveying system | 1 |

| 10 | Control system | 1 |

| Model | Screw diameter First step (mm) | Screw diameter Second step (mm) | Main motor kw | Second motor kw | Output Kg/h |

| 85/100 | 85 | 100 | 45/55 | 22 | 200 |

| 100/120 | 100 | 120 | 75/90 | 37 | 350 |

| 130/140 | 130 | 140 | 132 | 45 | 600 |

| 160/180 | 160 | 180 | 185 | 55 | 850 |

| 180/200 | 180 | 200 | 220-335 | 75 | 1200 |

3.Working processing

1.Belt conveyor will convey the material to Film Compactor/ Agglomerator

2.Film compactor/Agglomerator will cut film and compact the film by friction

3.The compacted film will be fed to Extruder by special design drop guide

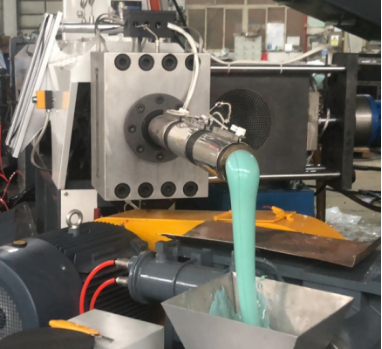

4.The screw extruder will have the processing of Plastified while the material fed to the extruder. And the vacuum degassing system will remove the water moisture of the material and clearance of low molecular to improve the quality of finished pellets

Advantage of he machine line

| Advantages | |

| 1 | Automatic design Siemens PLC control system |

| 2 | The Film compaction/ agglomerator is designed with observation window to facilitate customers to open,clean and change the blades

|

| 3 | The speed of the cutting motor of the compaction cylinder is adjustable to realize the closed-loop control of the speed of the extruder |

| 4 | The specially designed valve structure on the entrance of screw extruder, which effectively controls the moisture of the material entering the extruder, ensuring the stability of the discharge and the quality of the raw material

|

| 5 | Realize the continuous production of film transportation, crushing, compaction, extrusion, pelletizing, dehydration, collection and other processes, which saves electricity, improves product quality, and reduces labor intensity of workers; |

| 6 | The simultaneous recycling of leftovers and production waste saves customers storage space; |

|